67broncorebuild

Sr. Member

Hi guys, i have another question...

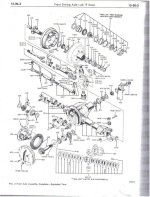

I have a D44 with the 78 bronco disks, with heim joints, rod over knuckle conversion.

I noticed today i have slop in the front wheels. I thought it might be lug nuts loose. I found out that wasnt the case.

I lifted it up, and the wheels have alot of play when i shake the wheel. Both will do this. I noticed the disks play with the wheel, so i made sure everything was tight(heim joints), and it still slops.

I am new to the D44 and componits. I have never opened one up.

Would it be as easy as a spindle nuts working loose?? Ball joints??

Thanks, any sugestions would help

I have a D44 with the 78 bronco disks, with heim joints, rod over knuckle conversion.

I noticed today i have slop in the front wheels. I thought it might be lug nuts loose. I found out that wasnt the case.

I lifted it up, and the wheels have alot of play when i shake the wheel. Both will do this. I noticed the disks play with the wheel, so i made sure everything was tight(heim joints), and it still slops.

I am new to the D44 and componits. I have never opened one up.

Would it be as easy as a spindle nuts working loose?? Ball joints??

Thanks, any sugestions would help