- Joined

- Jun 28, 2008

- Messages

- 691

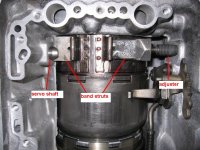

Changing the gaskets on my C4 that were leaking and now I can't get the servo back in. The spring is around the pin with the open mouth, and it feels like I'm stabbing it in there smoothly. I just can't push it in close enough to thread the screws.

Maybe the open mouth is not seating? Can you "feel" that or it's in when you can push the servo all the way in?

Maybe the open mouth is not seating? Can you "feel" that or it's in when you can push the servo all the way in?