krisbassett

Sr. Member

- Joined

- May 18, 2006

- Messages

- 568

Hey guys

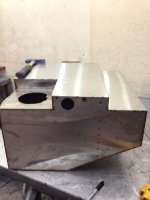

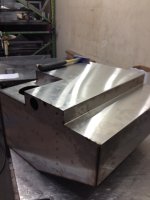

Thinking about building my own gas tank and I'm wondering what the best metal is going to be? I was thinking about 16ga stainless?

Thinking about building my own gas tank and I'm wondering what the best metal is going to be? I was thinking about 16ga stainless?