Rustytruck

Bronco Guru

- Joined

- Feb 24, 2002

- Messages

- 10,875

Fluid Leak down on the bore probably wont tell you any thing with the open ring end gaps. It will probably drain out very fast.

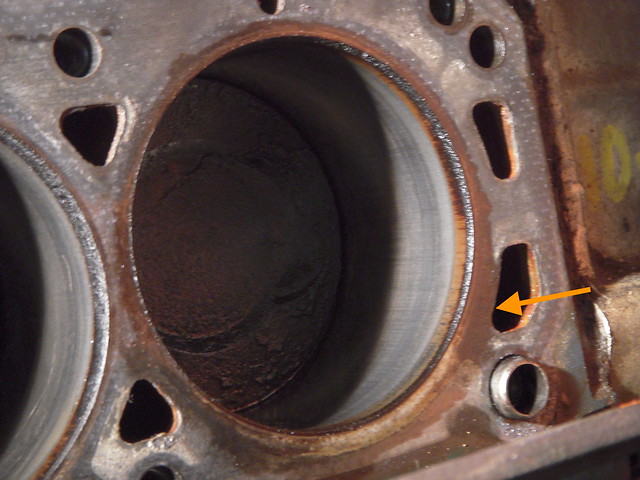

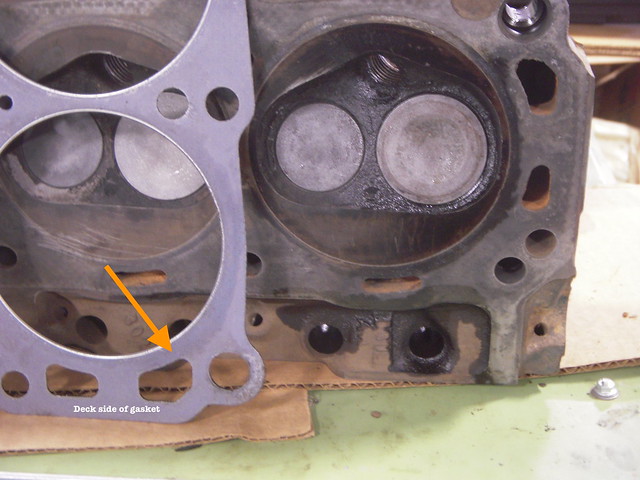

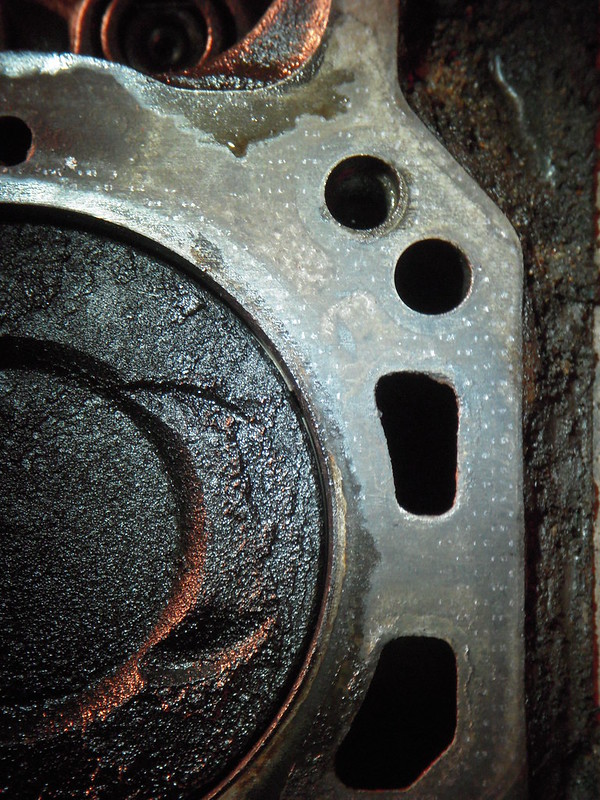

Once you get the head back on and valve train hooked up do a compression test before you put the intake back on. Saves a set of gaskets. Me I would just replace the other head gasket. What you going to do with 1 head gasket? They come in pairs. Make sure you get the head gaskets on right. The front marked on them is towards the radiator. In most cases there is a pretty side and an ugly side. When installed one side will be pretty side up and the other will be ugly side up. They will be stamped or printed front make sure both fronts are towards the front even if the gasket seems upside down and you cant read front unless you turn over the the gasket.

Look at the pictures on post 325 on this thread. properly installed head gaskets

http://classicbroncos.com/forums/showthread.php?t=287403&page=22

Once you get the head back on and valve train hooked up do a compression test before you put the intake back on. Saves a set of gaskets. Me I would just replace the other head gasket. What you going to do with 1 head gasket? They come in pairs. Make sure you get the head gaskets on right. The front marked on them is towards the radiator. In most cases there is a pretty side and an ugly side. When installed one side will be pretty side up and the other will be ugly side up. They will be stamped or printed front make sure both fronts are towards the front even if the gasket seems upside down and you cant read front unless you turn over the the gasket.

Look at the pictures on post 325 on this thread. properly installed head gaskets

http://classicbroncos.com/forums/showthread.php?t=287403&page=22