Repurposed a tool I made to remove the crankshaft pulley on my land cruiser. Flat stock from Home Depot & some holes.

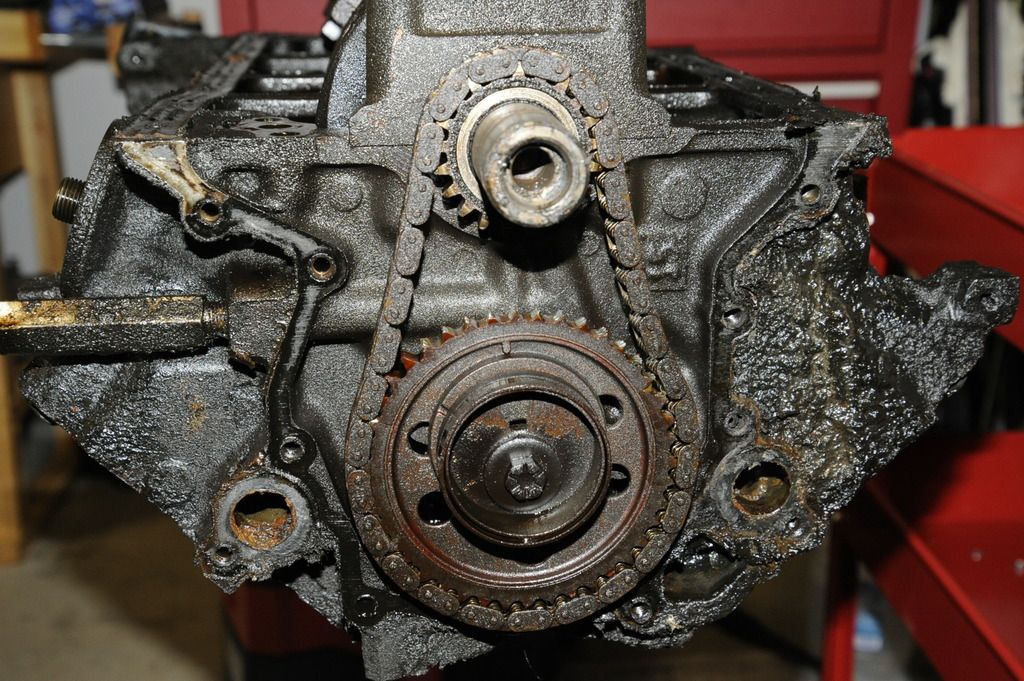

Nylon timing gear is worn to the aluminum. I'll take some closeups later.

Also, very slack chain.

The rearmost camshaft bearing had a lip which prevent me from pulling the camshaft out. I had to improvise another tool to draw it out. Bolt through large socket...

Nylon timing gear is worn to the aluminum. I'll take some closeups later.

Also, very slack chain.

The rearmost camshaft bearing had a lip which prevent me from pulling the camshaft out. I had to improvise another tool to draw it out. Bolt through large socket...