sp71eb

Sr. Member

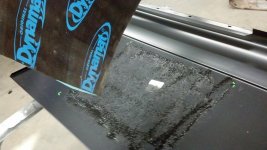

Hello everyone, I thought I would do a quick write up about skinning a bronco door. I am using a Dynacorn 68-77 Skin that I got from broncoparts4u. The bottom of the skin was rusted through and the door had molding holes that I didn't want to weld up, it also random dents and dings. The total of things wrong with the door made it a good candidate for a skin. From the factory the skin is single sided spot welded around the lip of the skin and also tack welded near the door frame and hinge mounts. There are two sets of three spot welds under where the vent window mounts. It is best to start by looking the door over and finding all of the welds and marking them.