bearskinner

Full Member

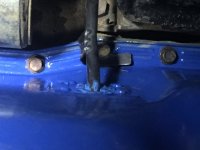

Has anyone braised or silver soldered the pressed in dip stick tube on a stock 302 oil pan? I'm sick of the leaky press in tube, but after taking off the pan, I'm wondering if I can get the pan back on with the tube permantly in place. It looks really tight, just wondering if it will even fit, once I mess with it tomorrow! I'm sure I'm not the only one to go thru this. Thanks for your replys