Ok, a bit later...

Adding a standard relay to the original non-relay type horn circuits (pre-'74) on a Bronco is relatively straightforward.

Get yourself a 30a or 40a rated (most common) cube relay generally known as a "Bosch Type" or "Hella Type" relay. Some will have just an 87 terminal pin, and some will have both an 87 and an 87A terminal. That's ok, but you will only use the 87 terminal. The 87A terminal is hot only when the switch is off, so you definitely don't want that!

You can literally mount this relay anywhere you want, but it's probably easiest for wiring if you put it near the horn itself. Driver's side within easy reach of the existing horn wire.

One less step in the wiring process this way.

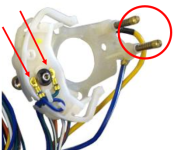

Before you mount the new relay, unplug the wire from the horn and connect it to the #86 pin on the relay. This will give you your mounting location, perhaps right on the wheel well brace that the horn is mounted to, based on the length of available original wire from the harness.

If you don't like this location, or the limitations of the length of the existing wire, now's the time to decide where you really want to mount the relay and then you can splice the needed length of wire to the original Ford horn wire.

Once this mounting process is over, here's where all new wiring starts. Might as well use 12 to 14 gauge wire for this project. A 16-22 gauge wire is fine for 85 and 86, but 30 and 87 need heavier wire. A 14 is probably fine for this, and a 12 is probably a bit overkill.

Up to you...

New wires to create are:

1. Pin #30 - Positive/Battery: A constant hot wire from pin 30 to a constant voltage source such as the battery side of the starter relay.

2. Pin #85 - Negative/Ground: A ground wire for the relay circuit only. Can be as short or as long as you need it to be to get from pin #85 to a well grounded bit of metal.

3. Pin #86 - Switched/Positive 12v: This is where your original horn wire is connected to act as a 12v switched source to energize the relay.

4. Pin #87 - Power to Horn: A wire from pin #87 runs directly to the horn where your old horn wire used to connect.

Done...

All you are doing is converting this so that your horn button now activates a relay (basically just a remote switch) which then powers the horn. Taking power over a shorter distance from the battery to the horn over a larger wire with fewer connections will help ensure that the horn receives full battery voltage any time it's needed. And it also reduces the current that passes through the original horn contacts up at the steering wheel so they no longer carry the full load of the horn. Just the milivolts it takes to energize the relay instead.

Clear as mud? Get the parts and stare at the horn for a minute and it'll all make sense.

Paul