|

You may not need all of these parts, it will depend on the condition of your

donor vehicle. My donor Bronco was missing the key retaining screw and

Iíve seen other Broncoís that just use a bolt and washer. All of these parts

can be found at other places for more money if you feel better about a

products quality because it costs more. Not that I donít think ďyou get

what you pay forĒ but in this case I think these are good quality parts.

Once I had all the parts it was time for the fun stuff.

Note: All torque specs are either from the 1973 Ford Truck shop manuals

or from a í73-í79 Haynes Ford Pickup & Bronco manual, unless otherwise

noted. You may want to double check the torque specs for your year.

Removal/Installation procedure

Note: Pay close attention to how things come apart. This will help you

with some of the reassembly. Also almost every part should be labeled

with left (L) or right (R). Left and right are as if you where sitting in the

Bronco. Be sure that you check that youíre on the correct side of the

Bronco for the part you have in your hand. One last thing before you

move one with the conversion, the knuckle stud configuration is setup so

you canít put the correct part on incorrectly. This will become clear during

the assembly of the parts. Take your time and have fun!

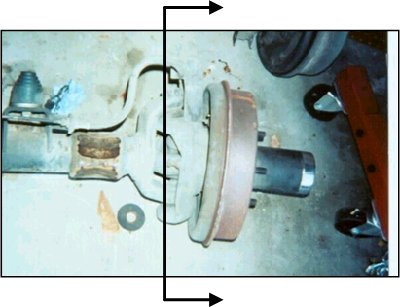

1. Remove the existing wheel locks, drums/brake assembly, spindle

and knuckle. I already had my tie-rod removed so I wonít cover

that piece. This removal of the drums, etc. was done by the shop

that rebuilt my axles so Iíll only be able to detail the pieces I know.

Besides, taking it apart is the easy part Ė right? Remove everything

to the right of the line (on both sides). See the picture just before

step two.

- The removal of the wheel locks should be self explanatory.

- You will need a special socket to remove/install the wheal

bearing locknut and the wheel bearing adjusting nut. I

bought mine at Kragen. There is a lockring washer between

these two nuts that has several holes in it. The wheel

bearing adjusting nut has a small pin that goes into one of

the holes of the retaining washer. You may or may not see

this pin; it may have been pushed into the nut due to

improper assembly. Once you have removed the wheel

bearing adjusting nut you can use a small nail to push the

pin out. This hardware should be interchangeable with the

spindles from your donor vehicle and you can use them if

you want.

- I believe the wheel drum and backing plate will come off as

one piece but I may be wrong. The axle shop did this part (I

asked them to leave it off since I was going to disc brakes. If

it doesn't come off as one piece you'll have to remove the

drum and figure it out, sorry.

- Remove the cotter pin from the upper ball joint and loosen

the castle nut. I believe you can get a wrench on the lower

ball joint's nut without removing your axle; you may have to

turn the yoke on the axle housing to give you a bit more

room. Then to remove the steering knuckle use a hammer

(dead blow, 5 lb sledge, etc) and hit the castle nut on the

upper ball joint. This will, eventually, cause the steering

knuckle to comes loose. Finish removing the nuts on the

upper and lower ball joint while holding the steering knuckle

so it doesn't drop on the outer axle shaft.

2. Before installing any of the new parts from the í79 Bronco I bead

blasted them and then painted.

3. Then I used a ball joint press to remove the old ball joints from the

í79 Bronco knuckles and then install the new ball joints. You can

borrow this tool from Autozone for free. It took a bit to figure out the

best way to use it but once you get it working itís easy. I wish I had

a picture of this but I was so into it once it started working that I

forgot all about the camera. The ball joint press I used looked like a

big C-clamp with a large piece of all-thread. The best tip I can give

you is put the C-clamp piece in a vise so it will hold everything for

you will you use a ratchet/breaker-bar to press the ball joints in/out.

-

The upper ball joints come with a zerk fitting and a plug. The

reason for this you need the zerk fitting to put grease in the

ball joint but you canít leave it in place because it will

interfere with the axle as it turns. You must install the plug

fitting after you put the grease in. The lower ball joint only

comes with a zerk fitting.

4. Install the steering knuckles on your axle. Torque the top ball joint

to 90ft-lbs. I also put 90ft-lbs of torque on the lower ball joint,

though I was unable to find a specific line item stating this setting.

5. At this point I noticed the spindle bore seal on my axle was

weathered and cracked. Autozone didnít even know what it was

even when I showed them the pictures below so I picked it up at the

local Ford dealership. It was cheaper to buy the kit that comes with

the spindle bore seal and a few other parts than to just buy the seal

alone. I actually used one of the other pieces Ė a wheel bearing

spacer. Itís a good thing because one of the original spacers didnít

make it back from the axle shop. Optional - Install the spindle bore

seal and any of the other parts.

6. Install the brake backing plate. They are label left and right and

should only go on at the correct angle. Youíll understand when you

try to install them. See picture in step #8.

7. Install the caliper holder. Again they are labeled and should only

go on one way. See picture in step #8.

8. Install the spindle. Tighten the nuts in a star pattern to make sure it

goes in evenly. Torque the nuts to 30 - 40ft-lbs.

9. Before you can install the hub/rotor assembly you have to install the

inner wheel bearing and seal (I think itís called the inner wheel

bearing seal) listed above, part #012035. If you get the same

hub/rotor assembly as I did youíll notice that both the inner and

outer bearing races are already installed. So you will end up with

four extra bearing races. Be sure and grease the bearings good

before you install them. The inner wheel bearing seal is a bit of a

pain to install. I covered the seal (metal and rubber) with a grease

rag and lightly hit it with a hammer and a 6Ē socket extension until it

was tightly seated.

10. Install the outer wheel bearing, donít forget the grease!

11. Have the wheel bearing adjusting nut on hand for this part. Make

sure the pin is sticking out of the adjusting nut; youíll need it later in

this step. Install the hub/rotor assembly and be careful not to knock

the outer wheel bearing out. Push the hub/rotor into place and you

should feel it seat. Install the wheel bearing adjusting nut and

ďTighten the adjusting nut to 50 ft-lbs while rotating the wheel/hub

assembly to seat the bearings. Back the adjusting nut of

approximately 90 degreesĒ Ė quoted from the Haynes manual (í73

Ford Truck shop manuals say the same thing).

12. The lockring washer goes on next. It has a tongue that will only

allow it to go on the spindle one way. This is trickery than you may

think; the pin on the adjusting nut mentioned in #11 must go

through one of the holes of the lockring. If it does not, remove the

lockring and adjust the wheel bearing adjusting nut to allow the pin

to go through the nearest hole in the lockring.

13. Install the wheel bearing lock nut and torque to 80-100 ft-lbs.

Check this specification for you vehicle. The picture below is the

installed hub/rotor.

14. Now the calipers. Iíve done disc brakes before but I must admit the

Ford floating caliper seems weird. Install the anti-rattle clip in the

bottom of the inner shoe and set the shoe in the caliper holder.

Install the outer shoe in the caliper and place the caliper on the

caliper holder. See the picture below.

15. Take the caliper support spring and key and install them as

described in the picture below. Install the key retaining screw (or a

bolt and washer) and torque 12-20 ft-lbs.

And the final productÖ..

Thatís pretty much it. I am still working on the brake lines; you canít just

buy í79 lines because the lines are to long. I may just cut them down and

put new ends on. Weíll see. Iíll update this document when I do. It

should be in the next week or so. If you have any questions just send me

an e-mail.

Ryan Flud

rflud@itprisms.com

This file also available in PDF format for Adobe Acrobat.

Update Ė 2.22.02

Since I wrote this article I have found the knuckles and spindles from the range of years listed above for much less than the $250 I paid. I have come to the conclusion that the place I purchased my parts from is extremely expensive. Keep an eye out for eBay auctions that are selling these parts and don't forget to check your local newspaper or the wrecking yards in your area. I have seen everything from the knuckle out as low as $40 (for both sides). Naturally this made me sick to my stomach. But the money is spent and the parts are installed. My suggestion Ė be patient and wait for a good deal not an amazing deal. If you wait for the amazing deal you will have drum brake for a very long time.

I was able to use my original brake hard lines. New flex lines from the caliper to the hard lines are required. I purchased the lines from BC Broncos (www.bcbroncos.com). They are stainless steel braided brake lines. You can get regular rubber flex lines for much less, just make sure you get D.O.T (Department of Transportation) certified lines. Take a look at the picture below.

No matter which disc brake conversion you do (Chevy or Ford) you will want to install a proportioning valve. I have yet to do this; I'm still in the process of rebuilding my EB. I've seen proportioning valve range from $50 to $110 depending on the type of proportioning valve. The standard proportioning valve you will see on most trucks (and stock '76-'77 EB's) goes for about $90 to $110. I will be to this point soon and I will include the pictures and install tips in this article when I'm done.

|