- Joined

- Dec 21, 2019

- Messages

- 77

Does anyone have pictures of how you've mounted 3 point seat belts to a bailie belt family cage? Or would 4 point's be recommended for the rear which attach to the stock floor location?

I have the Toms front/rear seats (headrests) that will be going in. The small kiddos will be in the back, one is still in a car seat for the next year or two.

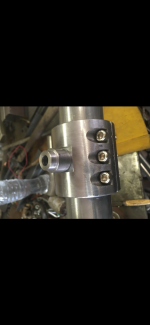

I've scoured the forum and see lots of different discussions. Some say just drill and through bolt. Some say a welded bung is the only way to go, which looks nice but unfortunately I can't weld. I can phone a friend to help with a weld if that the best option.

I want to have a plan before I powder coat the cage.

I have the Toms front/rear seats (headrests) that will be going in. The small kiddos will be in the back, one is still in a car seat for the next year or two.

I've scoured the forum and see lots of different discussions. Some say just drill and through bolt. Some say a welded bung is the only way to go, which looks nice but unfortunately I can't weld. I can phone a friend to help with a weld if that the best option.

I want to have a plan before I powder coat the cage.

Last edited: