Community

Message Forum

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Photo Gallery

Event Calendar

Book Reviews

Bronco Wallpaper

Bronco FAQ

Link Back to CB!

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Install the app

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

9" Gear Setup Experts

- Thread starter drewloch

- Start date

- Joined

- Oct 22, 2003

- Messages

- 1,020

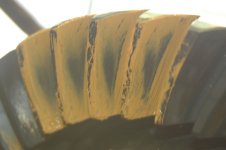

I think your pinion is a little too far out. Maybe you should adjust the carrier to get the pinion a little closer. Is your backlash in spec?

This Yukon instruction book has a pretty good explanation of contact pattern and adjustments.

http://www.ringpinion.com/downloads/yukoninstman.pdf#search="yukon gear"

I had to make several adjustments before I got mine to look like I thought it should. You can probably center the pattern up on the tooth a little better too. Sometimes they won't center up but mine looked just like that and a couple of moves later it was like this. I don't really know if this is a particularly good pattern but I have gotten a lot of miles out of it in the last two years without any problems.

This Yukon instruction book has a pretty good explanation of contact pattern and adjustments.

http://www.ringpinion.com/downloads/yukoninstman.pdf#search="yukon gear"

I had to make several adjustments before I got mine to look like I thought it should. You can probably center the pattern up on the tooth a little better too. Sometimes they won't center up but mine looked just like that and a couple of moves later it was like this. I don't really know if this is a particularly good pattern but I have gotten a lot of miles out of it in the last two years without any problems.

Attachments

The backlash was set to around .010 inches in that picture.

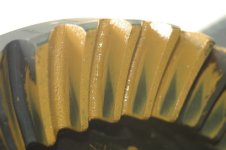

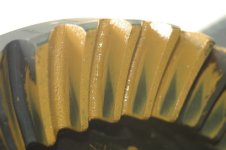

I thought it looked like the pinion was a little far out as well. I tried moving it in closer, but the pattern did not change as I expected. The below pictures show it .06 closer. I may just have to play with the backlash some more to see how that affects the pattern.

My other concern is that the backlash can be different up to .006 at different locations around the ring gear.

Thanks for the feedback.

Andrew

I thought it looked like the pinion was a little far out as well. I tried moving it in closer, but the pattern did not change as I expected. The below pictures show it .06 closer. I may just have to play with the backlash some more to see how that affects the pattern.

My other concern is that the backlash can be different up to .006 at different locations around the ring gear.

Thanks for the feedback.

Andrew

- Joined

- Oct 22, 2003

- Messages

- 1,020

That's a pretty big variation in backlash as you go around the gear. Is it seated on the carrier properly? I had some problems getting mine seated flat when I pressed it on the first time. I actually had to push it off and start over once. You probably should make another move. I know its irritating but it should eventually come into line a little better.

00gyrhed

Bronco Guru

- Joined

- Aug 3, 2006

- Messages

- 2,428

That is not the best pattern, you should try get it better, but sometimes normal wear will distort a proper pattern. If you go one way with the pinion and then back the other and it gets worse that may be the best you can get. I am not a gear expert I have only done about 10-15 setups. Most of the time you can get real nice picture perfect patterns. The resaon I responded is that I had that exact pattern in my 9" when I rebuilt it a few months ago. I took out shims and set back lash it got worse. I added shimms and adjusted backlash and it even made noise turning it by hand so after a full day of trying everything I could and much digust I left it with the pattern you have. Funny thing it was the exact shims that it came from Ford with. It runs quiet and cool.

I had the same problem as you are having with the varing backlash. The original Ford Manual says to set backlash between .008 and .012. The maximum variation in backlash arround the whole circle is not supposed to exceed .003. Ring gear runout is not to exceed .003 also. You are exceeding the backlash variation.

Here what I did because I am cheap not becuse it is right so no one flame me. I had no measurable ring gear runout when measured on the back of the ring gear. Obviously the problem was in the cut of the ring gear or possibly wear from runnot caused by the carrier I replaced?? Or possibly and I say this based on years on dinking with ford products (again do not flame me or I will send you a very long list of crap that left the factory way out of spec), It left the factory that way and ran 70K miles with no problem. Could be the pattern problem?? So in my cheapness I decided to set it up so that at my tightest backlash I had .008 (do not set it lower) and at my highest backlash I had .0013. I got the best pattern I could with that set up. Yes it took all day and the final pattern looked just like yours.

I am not happy with it. Even once it has 100K miles on it I will still worry that I should have just got another gear set and not been so cheap. My father was a greyhound mechanic in the 60's. They threw things together to keep the buses on the road. He always laughs at the convolutions I go through worring over patterns. His opinion is if it is quite it is good.

Once upon a time I had a 55 chevrolet with a 4.10 R&P. Very bad wear from the PO running it without oil. Close to the same design as the 9" only much weaker. I could not get it close. All the experts said the throw it away but the 4.10's were hard to come by (cheap anyway) so I decided to put it together the best I could and run it. It howled like a dog. Took it apart and adjusted it to the best drive pattern I could get, while ignoring the coast pattern. It was quiet in drive and howled in coast. Ran it behind the inline six standard tranmission for about 60K then put in a hopped up 350/700R4 Corvette TPI and ran it another 120K. Never had a problem, Pulled it apart twice and checked my magnet for abnormal metal wear. Never had a problem other than the howl in coast. After a while you learn how to drive it to keep it quiet.;D

If you are still with me check the ring gear runnout, and decide if you are cheap like me and willing to take a chance or if you want everything to be perfect and by the book.

I had the same problem as you are having with the varing backlash. The original Ford Manual says to set backlash between .008 and .012. The maximum variation in backlash arround the whole circle is not supposed to exceed .003. Ring gear runout is not to exceed .003 also. You are exceeding the backlash variation.

Here what I did because I am cheap not becuse it is right so no one flame me. I had no measurable ring gear runout when measured on the back of the ring gear. Obviously the problem was in the cut of the ring gear or possibly wear from runnot caused by the carrier I replaced?? Or possibly and I say this based on years on dinking with ford products (again do not flame me or I will send you a very long list of crap that left the factory way out of spec), It left the factory that way and ran 70K miles with no problem. Could be the pattern problem?? So in my cheapness I decided to set it up so that at my tightest backlash I had .008 (do not set it lower) and at my highest backlash I had .0013. I got the best pattern I could with that set up. Yes it took all day and the final pattern looked just like yours.

I am not happy with it. Even once it has 100K miles on it I will still worry that I should have just got another gear set and not been so cheap. My father was a greyhound mechanic in the 60's. They threw things together to keep the buses on the road. He always laughs at the convolutions I go through worring over patterns. His opinion is if it is quite it is good.

Once upon a time I had a 55 chevrolet with a 4.10 R&P. Very bad wear from the PO running it without oil. Close to the same design as the 9" only much weaker. I could not get it close. All the experts said the throw it away but the 4.10's were hard to come by (cheap anyway) so I decided to put it together the best I could and run it. It howled like a dog. Took it apart and adjusted it to the best drive pattern I could get, while ignoring the coast pattern. It was quiet in drive and howled in coast. Ran it behind the inline six standard tranmission for about 60K then put in a hopped up 350/700R4 Corvette TPI and ran it another 120K. Never had a problem, Pulled it apart twice and checked my magnet for abnormal metal wear. Never had a problem other than the howl in coast. After a while you learn how to drive it to keep it quiet.;D

If you are still with me check the ring gear runnout, and decide if you are cheap like me and willing to take a chance or if you want everything to be perfect and by the book.

Thanks for the information, it is certainly helpful.

This is a brand new Yukon ring and pinion set and a new ARB locker so I would like to determine why I am getting the variation in backlash around the ring gear. When mounting the ring gear I did as the directions indicated and heated the ring gear up in the oven to 200 degrees. The ring gear slipped onto the carrier and it sure looks like it is sitting evenly. I will measure the runout as it is mounted now and see if I need to try and remount the ring gear.

I have tried 6 different shim thicknessess and none of the patterns look as good as examples I have seen.

I too will be kicking myself for years if I think I could have done a better job and got a better pattern if I only tried some different settings.

I guess this weekend I will be spending lots of time playing with different shims and backlash.

Andrew

This is a brand new Yukon ring and pinion set and a new ARB locker so I would like to determine why I am getting the variation in backlash around the ring gear. When mounting the ring gear I did as the directions indicated and heated the ring gear up in the oven to 200 degrees. The ring gear slipped onto the carrier and it sure looks like it is sitting evenly. I will measure the runout as it is mounted now and see if I need to try and remount the ring gear.

I have tried 6 different shim thicknessess and none of the patterns look as good as examples I have seen.

I too will be kicking myself for years if I think I could have done a better job and got a better pattern if I only tried some different settings.

I guess this weekend I will be spending lots of time playing with different shims and backlash.

Andrew

- Joined

- Oct 22, 2003

- Messages

- 1,020

Funny, I used to live next to an older guy that had been a mechanic for many years. He worked on everything from heavy equipment to lawn mowers on a regular basis. he probably did hundreds of gear set ups and said the same thing 00gyrhed's dad said. If its quiet its good. Maybe those guys have it right.

I would try again and see what happens. If you just can't get a better pattern I would give it a try. I would also set the backlash at minimum at the tightest spot around your gear and let the other spots float wider as it turns. In a perfect world everything would be set just like the books say. It never actually works out that way. I grew up on a catle ranch in the middle of nowhere Wyo and we had a bunch of beater ranch trucks we were always putting back together. It was common for us to pull a driveline and use a rattle gun to tighten up a loose pinion. We just went until it "felt right". In all of the years we did that I can't remember a single failed gear set. Obviously, backlash wasn't in spec after that kind of treatment.

I would try again and see what happens. If you just can't get a better pattern I would give it a try. I would also set the backlash at minimum at the tightest spot around your gear and let the other spots float wider as it turns. In a perfect world everything would be set just like the books say. It never actually works out that way. I grew up on a catle ranch in the middle of nowhere Wyo and we had a bunch of beater ranch trucks we were always putting back together. It was common for us to pull a driveline and use a rattle gun to tighten up a loose pinion. We just went until it "felt right". In all of the years we did that I can't remember a single failed gear set. Obviously, backlash wasn't in spec after that kind of treatment.

00gyrhed

Bronco Guru

- Joined

- Aug 3, 2006

- Messages

- 2,428

There are expert rear end guys that will tell you that patterning R&P is an exact science, and that only the perfectly centered patch located low on the ring gear is acceptable. It needs to be low so that as load is applied the contact rises up the ring gear and not off the edge. I used to have an older book circa 1940's from Dana or Rockwell with good pictures of acceptable gear patterns. They vary more than the charts you see today. Did we get smarter or more anal? The main thing is that your patch when turned under load does not overlap the edge of the gear. Good rear end rebuilders will tell you that most of these "acceptable" patterns are no good. There is a well respected rear end guy here in Dallas that told me that they check every rear end they work on before they tear it down and that over 75% of the rear ends that leave the factory are not properly set up. Kind of makes you wonder. Some how they run quietly for hundreds of thousands of miles without problems without proper set up.

- Joined

- Oct 22, 2003

- Messages

- 1,020

I vote for more anal. The basic design and service requirements of a typical automotive rear end haven't changed much since the '40s. They can and will still take the same misalignments and abuse they always did.

I agree that a perfect contact pattern will provide optimal performance. Somewhere around here I have an old machine design text book that will go on forever about gear design and theory. The bottom line is that there is optimal performance and acceptable performance for any given service. Obviously, the OEMs have decided to shoot for acceptable performance. It must be good enough or they would be having warranty problems.

drewloch, I still think you get it as good as you can and give it a try. As long as it isn't an obviously bad contact pattern you should be fine.

I agree that a perfect contact pattern will provide optimal performance. Somewhere around here I have an old machine design text book that will go on forever about gear design and theory. The bottom line is that there is optimal performance and acceptable performance for any given service. Obviously, the OEMs have decided to shoot for acceptable performance. It must be good enough or they would be having warranty problems.

drewloch, I still think you get it as good as you can and give it a try. As long as it isn't an obviously bad contact pattern you should be fine.

I pulled the ring gear off and measured the runout on the new ARB locker.

There is .009" of runout on the locker. I was careful on how I mounted the ring gear on the locker, so I don't think I somehow warped the carrier. I would hope that isn't even possible.

I am going to try to rotate the ring gear to different positions on the carrier to see if any runout on the ring gear cancels out the carrier.

Has anyone ever heard of that amount of runout on an ARB carrier?

Thanks.

Andrew

There is .009" of runout on the locker. I was careful on how I mounted the ring gear on the locker, so I don't think I somehow warped the carrier. I would hope that isn't even possible.

I am going to try to rotate the ring gear to different positions on the carrier to see if any runout on the ring gear cancels out the carrier.

Has anyone ever heard of that amount of runout on an ARB carrier?

Thanks.

Andrew

- Joined

- Oct 22, 2003

- Messages

- 1,020

drewloch said:I pulled the ring gear off and measured the runout on the new ARB locker.

There is .009" of runout on the locker. I was careful on how I mounted the ring gear on the locker, so I don't think I somehow warped the carrier. I would hope that isn't even possible.

I am going to try to rotate the ring gear to different positions on the carrier to see if any runout on the ring gear cancels out the carrier.

Has anyone ever heard of that amount of runout on an ARB carrier?

Thanks.

Andrew

I haven't heard of any specific problems with ARB units in the past. However, I have done a fair amount of machine work over the years and .009" of runout on something as small as a carrier is terrible. Based on the way you installed the gear I would be very surprised if you warped the carrier. At least the runout is the same as you had with the ring installed. That indicates that the ring gear has basically zero runout, assuming you took your measurement at about the same radius from centerline.

How about the bearings? Are they seated properly? One of those slightly out could cause the carrier to wobble. Its a long shot on that but a possibility.

00gyrhed

Bronco Guru

- Joined

- Aug 3, 2006

- Messages

- 2,428

If your bearings are seated, which thay probably are, you need to take it back and make whoever you bought it from replace it. Do not deal with it anymore. .09 run out is way out of spec. Like minor said it is too much for a small part like that.

Similar threads

City: New York

Price: $Offers

- Replies

- 1

- Views

- 104

- Replies

- 4

- Views

- 1K