I am installing F3ZE Cobra GT40 heads with stock valve train on the ‘95 F150 roller cam 5.0 in my 73 Bronco. I wanted to check pushrod length, as I’m not sure if they’ve been resurfaced. I came across this discussion:

https://classicbroncos.com/forums/showthread.php?t=51328

“I'm assuming you're working on a stock 302 in the '72 EB listed in your

profile? from the factory that engine would have positive stop

(non-adjustable) lifters. the procedure for those would be to bottom

the nut (i.e. turn it until the pivot bottoms and turning torque increases)

then final torque the nut to 17-23 ft.lbs.

if you think your pushrod length and lifter preload is out of spec due to

engine changes then checking involves: turn crank/cam until valve being

checked has lifter on the cam base circle; tighten the nut down until you

achieve zero lash; then count the number of additional turns until the

nut bottoms out. if it takes 0.8 to 1.75 to go from zero lash to

bottoming then things are within spec and lifter is at proper pre-load.

otherwise you need +-0.060" pushrods“

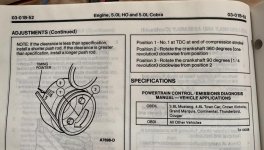

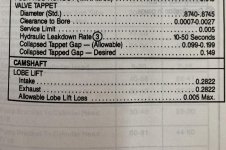

I tried doing that, but my results vary in and out of spec considerably depending on where I call zero lash (my lifters are bled down). The ‘95 Mustang manual calls out a procedure where the lifter is bottomed out and the rocker/valve stem clearance is measured (see manual excerpt).

The problem with that procedure is that it calls out a tool T71P-6513-B, which is kinda expensive (170$). Australians sell a less expensive variant, a Toledo 304032 or a T&E 92120, $40-60 US + shipping, works out to a C note.

At this point I’m thinking of trying to pump up my lifters by priming the oil pump, in order to get a more precise zero lash, vs fabbing a bleed down tool vs blowing it off, and torquing to 20 ft lbs and calling it done.

Any suggestions?

https://classicbroncos.com/forums/showthread.php?t=51328

“I'm assuming you're working on a stock 302 in the '72 EB listed in your

profile? from the factory that engine would have positive stop

(non-adjustable) lifters. the procedure for those would be to bottom

the nut (i.e. turn it until the pivot bottoms and turning torque increases)

then final torque the nut to 17-23 ft.lbs.

if you think your pushrod length and lifter preload is out of spec due to

engine changes then checking involves: turn crank/cam until valve being

checked has lifter on the cam base circle; tighten the nut down until you

achieve zero lash; then count the number of additional turns until the

nut bottoms out. if it takes 0.8 to 1.75 to go from zero lash to

bottoming then things are within spec and lifter is at proper pre-load.

otherwise you need +-0.060" pushrods“

I tried doing that, but my results vary in and out of spec considerably depending on where I call zero lash (my lifters are bled down). The ‘95 Mustang manual calls out a procedure where the lifter is bottomed out and the rocker/valve stem clearance is measured (see manual excerpt).

The problem with that procedure is that it calls out a tool T71P-6513-B, which is kinda expensive (170$). Australians sell a less expensive variant, a Toledo 304032 or a T&E 92120, $40-60 US + shipping, works out to a C note.

At this point I’m thinking of trying to pump up my lifters by priming the oil pump, in order to get a more precise zero lash, vs fabbing a bleed down tool vs blowing it off, and torquing to 20 ft lbs and calling it done.

Any suggestions?

Attachments

-

9EA1692E-A3B8-4A86-B22F-FD86057BE9AE.jpg122.8 KB · Views: 38

9EA1692E-A3B8-4A86-B22F-FD86057BE9AE.jpg122.8 KB · Views: 38 -

B707157E-5DFC-4EC8-9849-9A2F35102908.jpg178.7 KB · Views: 35

B707157E-5DFC-4EC8-9849-9A2F35102908.jpg178.7 KB · Views: 35 -

DA230053-1EBA-4F97-B297-35464805C72B.jpg113.4 KB · Views: 35

DA230053-1EBA-4F97-B297-35464805C72B.jpg113.4 KB · Views: 35 -

12481518-0357-42C6-B74C-E6237EC7FE06.jpg103.2 KB · Views: 25

12481518-0357-42C6-B74C-E6237EC7FE06.jpg103.2 KB · Views: 25 -

32EF45AC-2F6D-4A06-B077-524ED3A4F46E.jpg101.3 KB · Views: 30

32EF45AC-2F6D-4A06-B077-524ED3A4F46E.jpg101.3 KB · Views: 30