GreggAz

New Member

We have been working on this project for quite a while now, but it is finally a full time project and has some progress to show.

This 74 Bronco is being built of our customer, at All Ways Hot Rods. No we are not a dedicated off road shop, but we have been handling much of this customer's work, and he wanted to see the truck built to our style. It helps to have Driven right around the corner, and the truck would not be where it is now without their help.

We started with what looked to be a clean driver.

The Bronco was torn apart and found to be a little worse than expected.

Once torn apart we had quite a pile of parts that we were not using. All of the parts and interior went to Driven, where Randy can make good use of them.

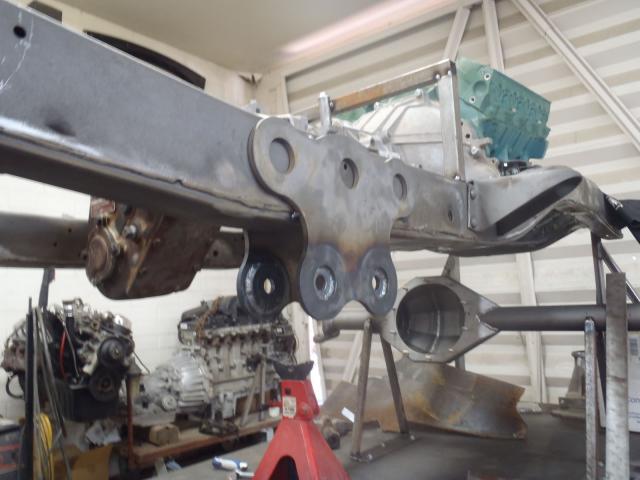

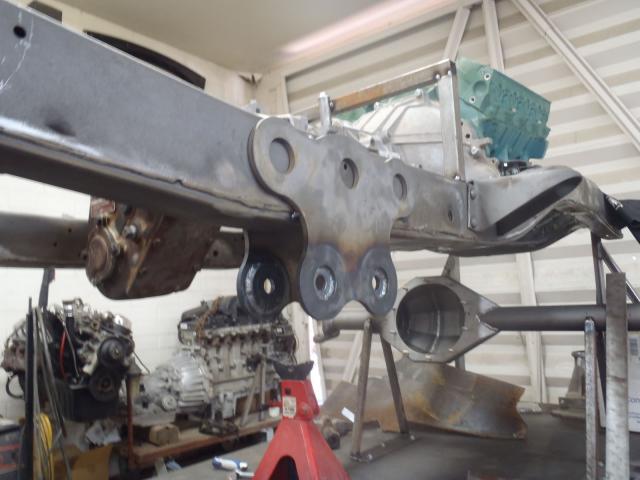

we separated the body and frame, and set the frame up on our table. Stripping off the mounts and brackets we didn't need readied the frame to be positioned on the table.

Currie provided the F9 housings front and rear. The front has D44 Cs, and a High pinion 3rd member.

We moved the front axle forward 1.5" and the rear back 2", and I started laying out the four link for the rear once everything was secure on the table.

I fit up a mockup motor and trans, and worked through advanced adapters not knowing how their own kit goes together.

Contrary to what AA will tell you, a 4R70W/AODE IS longer than an AOD.

Also the trans crossmember needs to move to the rear with this transmission, even though they insist that you can use the stock location.

all together it will not matter as I am going to build a tube crossmember to replace the factory part. I just needed to confirm that the parts were correct, and sitting in their proper location.

Then started fitting the links and brackets.

The engine is a 347 from Smedding, and will see our typical attention to detail.

Im off for lunch here on the 4th, Ill include more soon. We have some different ideas for the body, and finishes, and the Baer brakes showed up Friday, I just need some better photos.

Anybody who is interested can see many more photos here:

http://allwayshotrods.com/fgallery/46

and if you want to follow along as progress is made, I keep regular updates on our facebook page

http://www.facebook.com/pages/All-Ways-Hot-Rods/124908787581949

This 74 Bronco is being built of our customer, at All Ways Hot Rods. No we are not a dedicated off road shop, but we have been handling much of this customer's work, and he wanted to see the truck built to our style. It helps to have Driven right around the corner, and the truck would not be where it is now without their help.

We started with what looked to be a clean driver.

The Bronco was torn apart and found to be a little worse than expected.

Once torn apart we had quite a pile of parts that we were not using. All of the parts and interior went to Driven, where Randy can make good use of them.

we separated the body and frame, and set the frame up on our table. Stripping off the mounts and brackets we didn't need readied the frame to be positioned on the table.

Currie provided the F9 housings front and rear. The front has D44 Cs, and a High pinion 3rd member.

We moved the front axle forward 1.5" and the rear back 2", and I started laying out the four link for the rear once everything was secure on the table.

I fit up a mockup motor and trans, and worked through advanced adapters not knowing how their own kit goes together.

Contrary to what AA will tell you, a 4R70W/AODE IS longer than an AOD.

Also the trans crossmember needs to move to the rear with this transmission, even though they insist that you can use the stock location.

all together it will not matter as I am going to build a tube crossmember to replace the factory part. I just needed to confirm that the parts were correct, and sitting in their proper location.

Then started fitting the links and brackets.

The engine is a 347 from Smedding, and will see our typical attention to detail.

Im off for lunch here on the 4th, Ill include more soon. We have some different ideas for the body, and finishes, and the Baer brakes showed up Friday, I just need some better photos.

Anybody who is interested can see many more photos here:

http://allwayshotrods.com/fgallery/46

and if you want to follow along as progress is made, I keep regular updates on our facebook page

http://www.facebook.com/pages/All-Ways-Hot-Rods/124908787581949