Nothing Special

Sr. Member

- Joined

- Nov 25, 2016

- Messages

- 805

I'm setting up new gears in a Dana 44 high pinion for my '71 Bronco. I changed a differential once before, but since I didn't move the pinion it was quite a bit simpler. This time I'm starting from scratch.

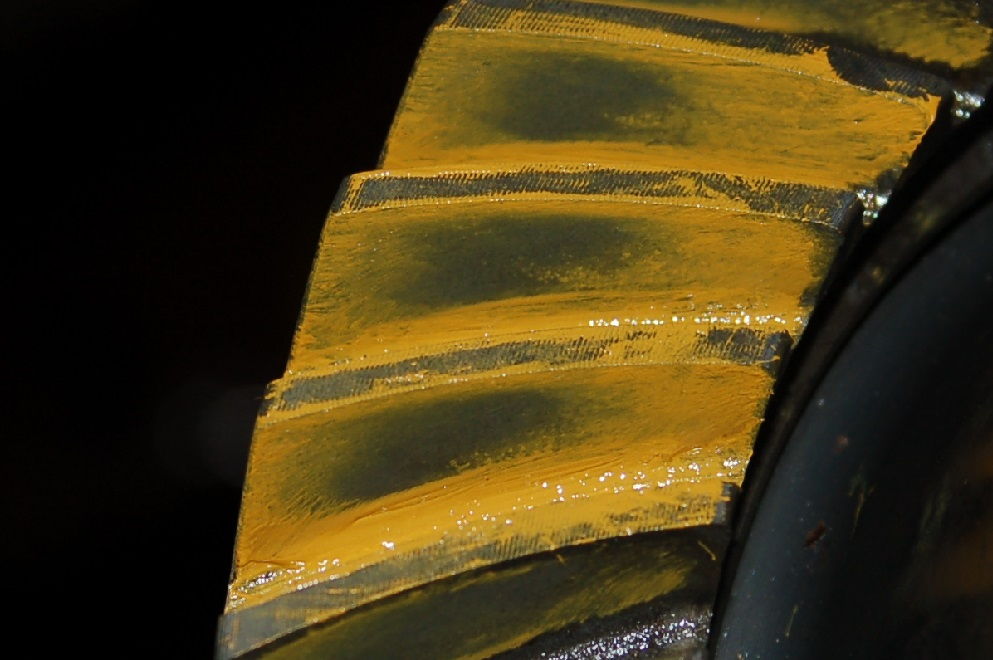

Here's my first attempt at a pattern. I know the backlash needs adjusting (it's at .004", should be .006" - .010"). And the total torque to turn is only 5 lb-in above the pinion torque to turn (should be 5 - 15 lb-in). So it could use a little more case preload. But I thought I'd take a look at the pattern and see if my first shot at pinion depth was anywhere close.

I'm thinking this looks pretty close, but maybe I could increase the pinion depth a little to get the pattern a little lower on the tooth.

Drive side:

Coast side:

What do people think? Should I get the backlash and case preload dialed in better before making any pinion depth adjustments? And does it look like increasing the pinion depth would be a good direction to go?

Thanks

Here's my first attempt at a pattern. I know the backlash needs adjusting (it's at .004", should be .006" - .010"). And the total torque to turn is only 5 lb-in above the pinion torque to turn (should be 5 - 15 lb-in). So it could use a little more case preload. But I thought I'd take a look at the pattern and see if my first shot at pinion depth was anywhere close.

I'm thinking this looks pretty close, but maybe I could increase the pinion depth a little to get the pattern a little lower on the tooth.

Drive side:

Coast side:

What do people think? Should I get the backlash and case preload dialed in better before making any pinion depth adjustments? And does it look like increasing the pinion depth would be a good direction to go?

Thanks