Ford's 6R80 is a super tough, 6 speed automatic that can easily handle 850/850 RWHP & torque all in a package almost identical in size to a 4R70W

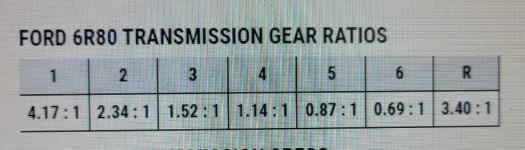

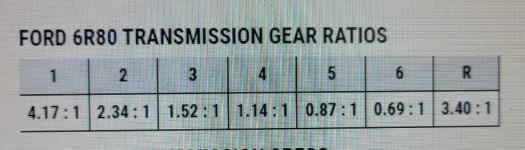

The 6R80 trans you want for a Bronco comes from an F150, with a 5.0, and must be a 4x4 model. It comes in 2009 through 2017 Ford F-150 pickups and other Fords. However, you do not want a 2011 or earlier model as they have several huge issues making them incompatible to a swap. So, the best years are '15 & up by far. The 6R has torque converter lockup capabilities in all 6 gears. The transmission has a 4.17 1st gear and with two overdrive gears, the highest of which is 0.69:1 making this a fantastic off road trans.

The 4.17;1 first gear is a huge boost for going slow while crawling or just plain helping you get going with larger tires and a taller gear ratio. Got your interest yet?

Swapping it into a SBF means using an adapter because the 6R is mated to Ford modular engines (the only one you want for the swap is the 5.0) so the bellhousing bolt pattern is not the same. Currently there are 2 companies making adapters: Performance Auto and Speed Gems. There are some very important differences between the 2 styles which I will address later.

The 6R will need a self-contained transmission controller to operate it in a Bronco behind a SBF. There is currently one reliable controller on the market. US Shift Quick6 allows complete control of all functions of the trans. From shift points, to line pressures, TC lockup or not, to shift harshness, the ability to use the trans in full automatic mode like a "normal" transmission right down to being able to put it into "manual" mode and operate the trans as if it was a stick but without a clutch. FULL manual control on every shift. Amazing what you can do with this trans. It gives you the best of both worlds- full auto or full manual or both. I've used US Shift (Baumann) controllers for 11 yrs. Great service with a great product. I highly recommend their product.

I will show pics of most of the modifications I needed to install one in my Bronco. I will also describe some of the major drawbacks with one of the bellhousing adapters used to mount it to a SBF and the problems caused by this adapter type & how to overcome some of those design problems.

What is amazing is the package size. The 6R80 & 4R70W are almost identical even with 2 more gears in the 6R. The bottom of the 6R is slightly wider than a 4R but the top is over an inch wider and the top of the trans sits higher than a 4R. My t-case cable shifter had over an inch of clearance with the 4R and now the 6R is touching the cable shifter bracket mounted to the tunnel. I think you will need at least a 1" BL or more for the 6R, it could be very tight fit with only 1" but you could easily raise the flat part of your tunnel height instead of more body lift. Essentially the 6R dimensions are a little wider at the top & up closer to the bellhousing end of it.

There are definitely a couple tight clearance spots when installing the 6R where a body lift won't help at all.

The front driveshaft clearance to the very most rearward, drivers side corner of the trans housing is close.. 1310 double carden joints clear, but some 1350 double carden joints can be more troublesome at best. I will show pics of mine clearing that corner of the case by less than the thickness of a steel rule and I know some that have ground that corner of the 6R case down for clearance. My front axle is not stock (HP D60) but I know for a fact that 6R's fit w/ stock D44's with driveline modifications.

The other tight spots are between the driveshaft and the shifter cable housing and where the shifter linkage is attached to the pan bolts can be a clearance issue. The last spot here is where the shifter cable actually attaches to the shifter mechanism on the side of the trans can also be tight. I have seen driveshafts made out of smaller diameter tubing to help clear these spots on Coyote installs with D44's.

6R to SBF Adapter choices: this gets detailed and long but I feel it's extremely important so you can make an informed decision before choosing an adapter

Performance Automatic was the first SBF to modular 6R80 mass produced adapter that I am aware of. I was looking to convert 5 yrs ago but US Shift was still testing their controller and bellhousing adapters weren't available yet.

The newcomer is Speed Gems which has recently released a SBF to modular 6R80 adapter (along with several others).

Here are a couple faults with the PA adapter.

1. First most obvious "fault" is you have to cut a hole in the bellhousing for your stock SBF starter to fit. Yeah, this one kept me from doing the swap for several years. I run a very healthy 460 SBF with 600hp/710ftlbs torque and I was (and still am) concerned about the starter fitment hole. I know enough guys running this adapter and so far no failures from the big HP Broncos with that hole.

I run a very healthy 460 SBF with 600hp/710ftlbs torque and I was (and still am) concerned about the starter fitment hole. I know enough guys running this adapter and so far no failures from the big HP Broncos with that hole.

Torque converter fitment has two more of these "faults" with the PA adapter. First is the fitment of the stock 6R TC onto the flex plate. There are 4 male/female standoffs in the adapter kit that are needed to space the TC appr. 1/2" farther from the flex plate and in order to do that you use the supplied stud extenders in the kit. These 4 guys screw into your TC in the stock location but the bolt pattern on the flexplate and the TC don't match perfectly. One being SAE and the other a metric pattern. This means that you need to round out, egg out or over drill the holes slightly in your SBF flexplate in order to fit the stock F150 TC that came with your trans. It's close but you need to do this or it won't fit and you'd better get the TC centered or you could wear out the front pump, the front seal and/or possibly have some vibration issues.

3. TC button or snout. This is the other TC "fault" with the PA adapter. The engine end of all TC's have a "button" that fits into the end of the crankshaft for centering it. PA's kit includes an "extender" that fits over the snout of the TC so when you bolt the 3/4" thick adapter ring to the block this snout extender in theory, fits over the TC snout and then fits into the end of the crankshaft. It must do this to compensate for the extra 3/4" you just bolted to the engine block AND to center it. Well, theory is theory. I now know of six of these 6R swaps with the PA adapter and not one of TC extenders when placed on the end of the TC fits into the end of the crank- not one. PA has been made aware of this (they denied anyone had called them when I did) and they say some of the converters are different, so they don't fit. Let me clarify- Ford doesn't put different sized torque converters with different lengths in the same trans in the same year, sorry PA, don't shine us along.

Performance Auto recommends NOT using the snout adapter if it interferes with the fit. PA says it's ... "common to not have a TC snout mounted in the end of a crankshaft ... and it will be fine". PA wants you to hang the TC on those 4 stud extenders in the holes you enlarged. Gotta be a reason why every OE manufacturer wants the end of the TC in the crankshaft right? I made some changes to the length of the TC snout in the pic below to make sure it would fit in the end of the crank.

4. The spacer ring that bolts up between engine block and trans bellhousing has 3 yes, three different size bolts mixed and matched between SAE and metric. PA, why design a new spacer that uses so many types and sizes and thread pitches? Also, this is a 2 pc adapter, see pic below. Not a big deal but definitely not a professionally engineered, well thought out design IMO.

The adapter ring doesn't seal at the back of the bellhousing between the top two bellhousing bolts because the adapter is made of two pcs and they don't meet at the top of the bellhousing. Why, other than the cost of another 5oz of alum, would any engineer leave the top of the bellhousing open to the elements? You can see that the left & right sides of the adapter stop just past the upper bellhousing bolts. Besides debri possibly getting in when wheeling any nut, bolt, small wrench, fittings ANY thing could drop into this opening when working and get stuck between the flexplate and block or TC possibly requiring transmission removal to remove. Poor design IMO. In my install I found a piece of extremely dense black self stick foam, trimmed it to fit and it completely fills this gap and looks decent too-stayed in place during the 7 times I R&R'd this while mocking up. Really? Foam to fill a hole for a $600 adapter kit? I asked PA and they said "filling the hole" wasn't needed. Come on guys.

Lot's here to wade thru but I have talked to 6 or 7 Bronco owners who have called me and/or emailed me about the issues listed above who have experienced the same issues with this adapter.

The standoffs used to space the TC back 1/2" are a design flaw. These spacers do not have enough footprint to spread the load of 710 ft lbs of torque and therefore the torque applied thru them from the flexplate to the TC puts undue amounts of stress in an extremely small footprint on the flexplate and this in turn causes the flexplate to crack around the shoulder of where these 4 stand offs bolt to the flex plate.

To make sure the next pic doesn't happen to you, you have several choices and none of the solutions are offered by the adapter kit made by PA.

Personally I think if you are running a stock SBF through these 4 stand off's, you might be fine. However, my 460SBF and a buddy with a 427 stroker have both had our flexplates crack severely or just break apart from these attachment points. To exaggerate the stress load a little, picture this: imagine two 12" discs attached by 4 evenly spaced pencils. One disc is the Flex plate and the other disc is the TC. Rotating one disc now transfers the energy into the pencils and to the other disc (a pencil length away) thru the pencils. Imagine the load on the edges of the pencil where they are attached to both discs when either of them are rotated. Tremendous load over an extremely small surface area. Major design flaw in my opinion. A couple friends are building their own TC to flexplate mounts described below.

There are two ways to fix this issue:

1- buy a custom-made longer TC so the pads that normally bolt up against a flexplate now do so like in a stock application. This will spread the load out and not crack the flexplate. I called but couldn't find any with a stall speed of less than 3500rpm.

2- weld 1/2" thick spacers to your F150 TC in the correct attachment point

locations and tap threads into those spacers to bolt your flexplate securely to it. This will give you the 1/2" spacing needed AND it will give your bolt together attachment points (btw TC & flexplate) a large contact surface area so your flex plate is not continually stressed & flexed. This will now make it easier to bolt your TC to your flexplate since you will be using bolts instead of studs.

I used an extremely HD SFI flexplate which was 50% thicker than the SFI flexplate that cracked so badly in my case, and I am hoping I don't have to go through this again. Heads up- don't think all SFI flexplates are the same because my first one that cracked apart was also SFI but it was almost 1/2 the thickness of my new one. I am hoping it is thick enough that it won't flex when load is put through the 4 TC spacer standoffs. I had 4 days before the Bronco Moab Safari and wasn't going to miss it . I hadn't thought of other ways to alleviate this design flaw yet as I was just trying to get my rig ready for Moab. A couple months later a friend had a trans shop tig 1/2" blocks of steel to his TC for mounting it to the flexplate. His is working great.

. I hadn't thought of other ways to alleviate this design flaw yet as I was just trying to get my rig ready for Moab. A couple months later a friend had a trans shop tig 1/2" blocks of steel to his TC for mounting it to the flexplate. His is working great.

TC snout- to overcome the ill-fitting adapter extension that is supposed to fit over the end of the TC snout and fit into the end of the crank, I had a friend machine a round piece of steel which would was welded onto the existing snout of the TC and would fit into the end of the crank/ We allowed approximately .001" clearance for centering it in the crank. This effectively lengthens the TC by 1/2" so it can and will be centered/supported in the end of the crank. He did the work in a lathe so it would be centered perfectly. I then carefully redrilled holes in my flexplate with a step bit appr .004" larger so the TC would be centered on the flexplate.

Last drawback of the PA adapter is the large opening at the bottom of the adapter (bottom of the flexplate). Like the top of the TC/bell housing area it is open to the elements. Like I mentioned above, without modifying the PA adapter, both the top of the bell housing area is open to the elements and so is the bottom.

Speed Gems adapter

Here are comments and faults with their adapter.

I have followed their design since their first couple "look what we're building" pics. The Speed Gem adapter between the block and trans is literally a single piece of alum approx 2" thick. It easily solves the hole at the top & bottom of the issue. As you can see in the 2nd pic its design gives a large mounting pad with lots of surface area for the TC to bolt on to. You might say "what the heck is that big thing with the 4 holes in it" but that is the spacer to mount the TC to so it orients it properly and you can see the snout extension on this piece which allows the TC to fit into the end of the crank and it's all made out of a single pc of billet aluminum. With a single pc of alum they improved upon the cracking flexplate issue and the support & potential alignment issue by having to enlarge the holes in your flexplate on the PA adapter

The Speed Gem adapter does cover the entire TC & behellhousing all 360 degrees with a removable access plate on the bottom (like some OE applications).

There are two drawbacks to this Speed Gem design from a design standpoint and talking to guys that have used it.

1- The weight of the spacer that the TC mounts to is 13 #'s. Racers know that instant throttle response and less mass (always determined by whether the weight is close to the center or farther from the center) in the drivetrain quickens ET's. Well, we aren't racers but 13 #'s in addition to the TC does affect inertia and it takes some torque to get that extra weight moving. Speed Gems said they worked hard at reducing the spacer ring weight to a minimum and they say they have zero issues with excessive HP/torque handling abilities. A friend pointed out the comparison to a heavy flywheel, clutch and disc for a manual trans. I have not weighed the difference btw these two (including a TC) but it is what it is and we will go from there.

2- You must use their proprietary "made in USA" starter. I don't see this as a real reason to not buy it but I would tear this starter apart and find all the wear items in this starter and carry replacements at all times. You don't want to be out on vacation a thousand miles from home and need a starter you have to order from only one company that hopefully is still in business, open that day or even has the parts in stock!! When you can't purchase a proprietary starter locally and having the possibility of being "broke down" for a week isn't what you want then I suggest you buy a spare for cheap insurance- keep it at camp maybe.

Hope this wasn't too much info but this 6R80 swap isn't inexpensive and having expensive surprises popup midway through your installation isn't what you want.

Let's move to the output end of the 6R and the adapters that allow you to hang an Atlas or 205 to it. Ford doesn't seem to want to help hot rodders often the last 90 years with interchangeability since Ford changes parts, bellhousing bolt patterns, engine balancing weight amounts, wiring, etc, etc so often but they STILL have 31 spline output shafts and the standard 6 bolt pattern on their 4x4 tranny's for a transfer case to hang on. Nice, thx Ford.

Advance Adapters makes an adapter that allows an Atlas to fit on the 6R or a D20 to fit. I was told with very slight modifications in your home shop you can use the D20 adapter to install your NP205 if you want some Beef!

Atlas makes 2 adapters that fit a "Ford" 6R. I chose the longer of the two offered by AA because when bolted together the longer shaft (remember, this does not change the overall length of the adapter/trans assembly) gives my stroker almost one more inch of shaft engagement making it less likely that my 600hp/710ftlbs of torque will strip off any splines. SInce it doesn't add any length, I thought I'd give it a try and you can see in the pics that it fits perfectly with a little clearancing. AA unless asked specifically will sell the shorter one so inexperienced people might not just force it together and try "stucking it up".

Fitment issues:

I briefly mentioned that fitment becomes an issue due to the rear of the case being slightly wider than a 4R and it is a bit taller also. Your driveshaft will be extremely close to the drivers side, rear corner of the 6R case and the tube part of the driveshaft will be extremely close to your shift cable and bracket. There are creative ways to work around this but I thought I would mention this ahead of time and include pic's of what's working for me. High pinion differentials, D60's, narrowed or full width front ends, stock D20, NP205's or Atlas t-cases and how they are clocked all add a lot of variables to potential interference. Some builders are using smaller diameter tube drivelines up front to help add more clearance for the shifter

Obviously, since the 6R is a different trans and the mounts are different, you will need to make a crossmember. Seems like Coyote guys like to spend more $$ than SBF guys because several of the vendors offer crossmembers for the Coyote swap but I haven't seen any crossmembers for mounting a 6R behind a SBF swap- yet. lol

because several of the vendors offer crossmembers for the Coyote swap but I haven't seen any crossmembers for mounting a 6R behind a SBF swap- yet. lol

When installing the torque converter prior to installing the tranny make sure the TC is seated ALL the way back on the input shaft. It usually takes 3 distinct "clicks" before the TC is seated properly. If you've only felt the TC slide back and stop 2x, t is NOT seated all the way back. Slide it off and do it again. If you try installing and bolting it up w/o it being seated properly you will ruin the pump. When seated properly upon installation you should have at least .050" gap between the TC & flexplate surface mounting areas. In other words the TC needs to be able to slide forward and back at least .050" when the bellhousing is bolted up tight. If it doesn't you don't have the TC slid back far enough and might have ruined the front pump already.

Besides doing a visual check of my 30,000 mile 2015, 6R80 used trans I installed a new filter and I decided to install a Sure Cool Temp Control Bypass Valve to allow full coolant flow at all times. OE defaults to closed loop which eliminates coolant flow to any oil coolers therefore burning up your trans if or when it fails. Talked to SureCool and the sales guy says they send more than 10 of these a week in the summer to Saudi Arabia!!! lol I hope to have the same reliable no over heating issue with my 6R that I enjoyed with my 4R for 11 yrs even with one less cooler.

On the outside of the engine on the drivers side there are two oil coolant lines. These MUST be adapted to 1/2" lines or -8AN lines. Do not reduce the ID to anything smaller. There are some really well built adapters allowing the use of AN fittings directly to the coolant lines so you don't have to use metal lines. What I heard from Karl at USShift was this, "it is extremely important to use the 1/2" lines for the 6R80. Think of it this way, have you ever heard of any auto manufacturer to ever spend more money on a part than needed"?? Why would they use 1/2" lines when 3/8" lines and fittings are cheaper." Good point Karl.

Ford says "who needs a dip stick"? Since it costs money, they were dropped!! Kind of explains why Ford spent the extra money on 1/2" lines-if it's needed, then they spend the money! IF it's not, then don't! lol . To check the trans fluid level you need to get under your rig and in the front passenger side corner of the trans there is a 17mm cap that comes off to reveal a short "dipstick" to show fluid level. The 6R holds appr 12 1/2 qts of Mercon LV. It's full synthetic and isn't cheap at appr $10 qt.

This is one sweet trans. It has smooth, close shifts and offers many driving & shifting options with the 6R controller from USShift that were unheard in earlier auto trannys. I have had 7 different trannys in my same Bronco. A stock 3spd, 3spd w/OD, C4, 4spd toploader, ZF. 4R70w and now my favorite, the 6R. Several of these over the decades were coupled to doublers. But this 6R80 to me is the best trans for a Bronco in all driving situations. The super low first gear, 2 overdrives, close gear ratios, torque converter multiplication that essentially increases your gearing by 2x, compact size, full manual shifting ability, handles amazing power input in stock form, fits our Broncos w/o too many mod's... I like it and hope you do too.

Please check out my build thread that I did here on CB detailing this 6R swap and many other upgrades, go to this page https://classicbroncos.com/forums/showthread.php?t=278607&page=22

and scroll down to Post # 329. There will be more posts, more pics and more unusable information for ya to look at!

Good luck with your 6R80 swap

The 6R80 trans you want for a Bronco comes from an F150, with a 5.0, and must be a 4x4 model. It comes in 2009 through 2017 Ford F-150 pickups and other Fords. However, you do not want a 2011 or earlier model as they have several huge issues making them incompatible to a swap. So, the best years are '15 & up by far. The 6R has torque converter lockup capabilities in all 6 gears. The transmission has a 4.17 1st gear and with two overdrive gears, the highest of which is 0.69:1 making this a fantastic off road trans.

The 4.17;1 first gear is a huge boost for going slow while crawling or just plain helping you get going with larger tires and a taller gear ratio. Got your interest yet?

Swapping it into a SBF means using an adapter because the 6R is mated to Ford modular engines (the only one you want for the swap is the 5.0) so the bellhousing bolt pattern is not the same. Currently there are 2 companies making adapters: Performance Auto and Speed Gems. There are some very important differences between the 2 styles which I will address later.

The 6R will need a self-contained transmission controller to operate it in a Bronco behind a SBF. There is currently one reliable controller on the market. US Shift Quick6 allows complete control of all functions of the trans. From shift points, to line pressures, TC lockup or not, to shift harshness, the ability to use the trans in full automatic mode like a "normal" transmission right down to being able to put it into "manual" mode and operate the trans as if it was a stick but without a clutch. FULL manual control on every shift. Amazing what you can do with this trans. It gives you the best of both worlds- full auto or full manual or both. I've used US Shift (Baumann) controllers for 11 yrs. Great service with a great product. I highly recommend their product.

I will show pics of most of the modifications I needed to install one in my Bronco. I will also describe some of the major drawbacks with one of the bellhousing adapters used to mount it to a SBF and the problems caused by this adapter type & how to overcome some of those design problems.

What is amazing is the package size. The 6R80 & 4R70W are almost identical even with 2 more gears in the 6R. The bottom of the 6R is slightly wider than a 4R but the top is over an inch wider and the top of the trans sits higher than a 4R. My t-case cable shifter had over an inch of clearance with the 4R and now the 6R is touching the cable shifter bracket mounted to the tunnel. I think you will need at least a 1" BL or more for the 6R, it could be very tight fit with only 1" but you could easily raise the flat part of your tunnel height instead of more body lift. Essentially the 6R dimensions are a little wider at the top & up closer to the bellhousing end of it.

There are definitely a couple tight clearance spots when installing the 6R where a body lift won't help at all.

The front driveshaft clearance to the very most rearward, drivers side corner of the trans housing is close.. 1310 double carden joints clear, but some 1350 double carden joints can be more troublesome at best. I will show pics of mine clearing that corner of the case by less than the thickness of a steel rule and I know some that have ground that corner of the 6R case down for clearance. My front axle is not stock (HP D60) but I know for a fact that 6R's fit w/ stock D44's with driveline modifications.

The other tight spots are between the driveshaft and the shifter cable housing and where the shifter linkage is attached to the pan bolts can be a clearance issue. The last spot here is where the shifter cable actually attaches to the shifter mechanism on the side of the trans can also be tight. I have seen driveshafts made out of smaller diameter tubing to help clear these spots on Coyote installs with D44's.

6R to SBF Adapter choices: this gets detailed and long but I feel it's extremely important so you can make an informed decision before choosing an adapter

Performance Automatic was the first SBF to modular 6R80 mass produced adapter that I am aware of. I was looking to convert 5 yrs ago but US Shift was still testing their controller and bellhousing adapters weren't available yet.

The newcomer is Speed Gems which has recently released a SBF to modular 6R80 adapter (along with several others).

Here are a couple faults with the PA adapter.

1. First most obvious "fault" is you have to cut a hole in the bellhousing for your stock SBF starter to fit. Yeah, this one kept me from doing the swap for several years.

Torque converter fitment has two more of these "faults" with the PA adapter. First is the fitment of the stock 6R TC onto the flex plate. There are 4 male/female standoffs in the adapter kit that are needed to space the TC appr. 1/2" farther from the flex plate and in order to do that you use the supplied stud extenders in the kit. These 4 guys screw into your TC in the stock location but the bolt pattern on the flexplate and the TC don't match perfectly. One being SAE and the other a metric pattern. This means that you need to round out, egg out or over drill the holes slightly in your SBF flexplate in order to fit the stock F150 TC that came with your trans. It's close but you need to do this or it won't fit and you'd better get the TC centered or you could wear out the front pump, the front seal and/or possibly have some vibration issues.

3. TC button or snout. This is the other TC "fault" with the PA adapter. The engine end of all TC's have a "button" that fits into the end of the crankshaft for centering it. PA's kit includes an "extender" that fits over the snout of the TC so when you bolt the 3/4" thick adapter ring to the block this snout extender in theory, fits over the TC snout and then fits into the end of the crankshaft. It must do this to compensate for the extra 3/4" you just bolted to the engine block AND to center it. Well, theory is theory. I now know of six of these 6R swaps with the PA adapter and not one of TC extenders when placed on the end of the TC fits into the end of the crank- not one. PA has been made aware of this (they denied anyone had called them when I did) and they say some of the converters are different, so they don't fit. Let me clarify- Ford doesn't put different sized torque converters with different lengths in the same trans in the same year, sorry PA, don't shine us along.

Performance Auto recommends NOT using the snout adapter if it interferes with the fit. PA says it's ... "common to not have a TC snout mounted in the end of a crankshaft ... and it will be fine". PA wants you to hang the TC on those 4 stud extenders in the holes you enlarged. Gotta be a reason why every OE manufacturer wants the end of the TC in the crankshaft right? I made some changes to the length of the TC snout in the pic below to make sure it would fit in the end of the crank.

4. The spacer ring that bolts up between engine block and trans bellhousing has 3 yes, three different size bolts mixed and matched between SAE and metric. PA, why design a new spacer that uses so many types and sizes and thread pitches? Also, this is a 2 pc adapter, see pic below. Not a big deal but definitely not a professionally engineered, well thought out design IMO.

The adapter ring doesn't seal at the back of the bellhousing between the top two bellhousing bolts because the adapter is made of two pcs and they don't meet at the top of the bellhousing. Why, other than the cost of another 5oz of alum, would any engineer leave the top of the bellhousing open to the elements? You can see that the left & right sides of the adapter stop just past the upper bellhousing bolts. Besides debri possibly getting in when wheeling any nut, bolt, small wrench, fittings ANY thing could drop into this opening when working and get stuck between the flexplate and block or TC possibly requiring transmission removal to remove. Poor design IMO. In my install I found a piece of extremely dense black self stick foam, trimmed it to fit and it completely fills this gap and looks decent too-stayed in place during the 7 times I R&R'd this while mocking up. Really? Foam to fill a hole for a $600 adapter kit? I asked PA and they said "filling the hole" wasn't needed. Come on guys.

Lot's here to wade thru but I have talked to 6 or 7 Bronco owners who have called me and/or emailed me about the issues listed above who have experienced the same issues with this adapter.

The standoffs used to space the TC back 1/2" are a design flaw. These spacers do not have enough footprint to spread the load of 710 ft lbs of torque and therefore the torque applied thru them from the flexplate to the TC puts undue amounts of stress in an extremely small footprint on the flexplate and this in turn causes the flexplate to crack around the shoulder of where these 4 stand offs bolt to the flex plate.

To make sure the next pic doesn't happen to you, you have several choices and none of the solutions are offered by the adapter kit made by PA.

Personally I think if you are running a stock SBF through these 4 stand off's, you might be fine. However, my 460SBF and a buddy with a 427 stroker have both had our flexplates crack severely or just break apart from these attachment points. To exaggerate the stress load a little, picture this: imagine two 12" discs attached by 4 evenly spaced pencils. One disc is the Flex plate and the other disc is the TC. Rotating one disc now transfers the energy into the pencils and to the other disc (a pencil length away) thru the pencils. Imagine the load on the edges of the pencil where they are attached to both discs when either of them are rotated. Tremendous load over an extremely small surface area. Major design flaw in my opinion. A couple friends are building their own TC to flexplate mounts described below.

There are two ways to fix this issue:

1- buy a custom-made longer TC so the pads that normally bolt up against a flexplate now do so like in a stock application. This will spread the load out and not crack the flexplate. I called but couldn't find any with a stall speed of less than 3500rpm.

2- weld 1/2" thick spacers to your F150 TC in the correct attachment point

locations and tap threads into those spacers to bolt your flexplate securely to it. This will give you the 1/2" spacing needed AND it will give your bolt together attachment points (btw TC & flexplate) a large contact surface area so your flex plate is not continually stressed & flexed. This will now make it easier to bolt your TC to your flexplate since you will be using bolts instead of studs.

I used an extremely HD SFI flexplate which was 50% thicker than the SFI flexplate that cracked so badly in my case, and I am hoping I don't have to go through this again. Heads up- don't think all SFI flexplates are the same because my first one that cracked apart was also SFI but it was almost 1/2 the thickness of my new one. I am hoping it is thick enough that it won't flex when load is put through the 4 TC spacer standoffs. I had 4 days before the Bronco Moab Safari and wasn't going to miss it

TC snout- to overcome the ill-fitting adapter extension that is supposed to fit over the end of the TC snout and fit into the end of the crank, I had a friend machine a round piece of steel which would was welded onto the existing snout of the TC and would fit into the end of the crank/ We allowed approximately .001" clearance for centering it in the crank. This effectively lengthens the TC by 1/2" so it can and will be centered/supported in the end of the crank. He did the work in a lathe so it would be centered perfectly. I then carefully redrilled holes in my flexplate with a step bit appr .004" larger so the TC would be centered on the flexplate.

Last drawback of the PA adapter is the large opening at the bottom of the adapter (bottom of the flexplate). Like the top of the TC/bell housing area it is open to the elements. Like I mentioned above, without modifying the PA adapter, both the top of the bell housing area is open to the elements and so is the bottom.

Speed Gems adapter

Here are comments and faults with their adapter.

I have followed their design since their first couple "look what we're building" pics. The Speed Gem adapter between the block and trans is literally a single piece of alum approx 2" thick. It easily solves the hole at the top & bottom of the issue. As you can see in the 2nd pic its design gives a large mounting pad with lots of surface area for the TC to bolt on to. You might say "what the heck is that big thing with the 4 holes in it" but that is the spacer to mount the TC to so it orients it properly and you can see the snout extension on this piece which allows the TC to fit into the end of the crank and it's all made out of a single pc of billet aluminum. With a single pc of alum they improved upon the cracking flexplate issue and the support & potential alignment issue by having to enlarge the holes in your flexplate on the PA adapter

The Speed Gem adapter does cover the entire TC & behellhousing all 360 degrees with a removable access plate on the bottom (like some OE applications).

There are two drawbacks to this Speed Gem design from a design standpoint and talking to guys that have used it.

1- The weight of the spacer that the TC mounts to is 13 #'s. Racers know that instant throttle response and less mass (always determined by whether the weight is close to the center or farther from the center) in the drivetrain quickens ET's. Well, we aren't racers but 13 #'s in addition to the TC does affect inertia and it takes some torque to get that extra weight moving. Speed Gems said they worked hard at reducing the spacer ring weight to a minimum and they say they have zero issues with excessive HP/torque handling abilities. A friend pointed out the comparison to a heavy flywheel, clutch and disc for a manual trans. I have not weighed the difference btw these two (including a TC) but it is what it is and we will go from there.

2- You must use their proprietary "made in USA" starter. I don't see this as a real reason to not buy it but I would tear this starter apart and find all the wear items in this starter and carry replacements at all times. You don't want to be out on vacation a thousand miles from home and need a starter you have to order from only one company that hopefully is still in business, open that day or even has the parts in stock!! When you can't purchase a proprietary starter locally and having the possibility of being "broke down" for a week isn't what you want then I suggest you buy a spare for cheap insurance- keep it at camp maybe.

Hope this wasn't too much info but this 6R80 swap isn't inexpensive and having expensive surprises popup midway through your installation isn't what you want.

Let's move to the output end of the 6R and the adapters that allow you to hang an Atlas or 205 to it. Ford doesn't seem to want to help hot rodders often the last 90 years with interchangeability since Ford changes parts, bellhousing bolt patterns, engine balancing weight amounts, wiring, etc, etc so often but they STILL have 31 spline output shafts and the standard 6 bolt pattern on their 4x4 tranny's for a transfer case to hang on. Nice, thx Ford.

Advance Adapters makes an adapter that allows an Atlas to fit on the 6R or a D20 to fit. I was told with very slight modifications in your home shop you can use the D20 adapter to install your NP205 if you want some Beef!

Atlas makes 2 adapters that fit a "Ford" 6R. I chose the longer of the two offered by AA because when bolted together the longer shaft (remember, this does not change the overall length of the adapter/trans assembly) gives my stroker almost one more inch of shaft engagement making it less likely that my 600hp/710ftlbs of torque will strip off any splines. SInce it doesn't add any length, I thought I'd give it a try and you can see in the pics that it fits perfectly with a little clearancing. AA unless asked specifically will sell the shorter one so inexperienced people might not just force it together and try "stucking it up".

Fitment issues:

I briefly mentioned that fitment becomes an issue due to the rear of the case being slightly wider than a 4R and it is a bit taller also. Your driveshaft will be extremely close to the drivers side, rear corner of the 6R case and the tube part of the driveshaft will be extremely close to your shift cable and bracket. There are creative ways to work around this but I thought I would mention this ahead of time and include pic's of what's working for me. High pinion differentials, D60's, narrowed or full width front ends, stock D20, NP205's or Atlas t-cases and how they are clocked all add a lot of variables to potential interference. Some builders are using smaller diameter tube drivelines up front to help add more clearance for the shifter

Obviously, since the 6R is a different trans and the mounts are different, you will need to make a crossmember. Seems like Coyote guys like to spend more $$ than SBF guys

When installing the torque converter prior to installing the tranny make sure the TC is seated ALL the way back on the input shaft. It usually takes 3 distinct "clicks" before the TC is seated properly. If you've only felt the TC slide back and stop 2x, t is NOT seated all the way back. Slide it off and do it again. If you try installing and bolting it up w/o it being seated properly you will ruin the pump. When seated properly upon installation you should have at least .050" gap between the TC & flexplate surface mounting areas. In other words the TC needs to be able to slide forward and back at least .050" when the bellhousing is bolted up tight. If it doesn't you don't have the TC slid back far enough and might have ruined the front pump already.

Besides doing a visual check of my 30,000 mile 2015, 6R80 used trans I installed a new filter and I decided to install a Sure Cool Temp Control Bypass Valve to allow full coolant flow at all times. OE defaults to closed loop which eliminates coolant flow to any oil coolers therefore burning up your trans if or when it fails. Talked to SureCool and the sales guy says they send more than 10 of these a week in the summer to Saudi Arabia!!! lol I hope to have the same reliable no over heating issue with my 6R that I enjoyed with my 4R for 11 yrs even with one less cooler.

On the outside of the engine on the drivers side there are two oil coolant lines. These MUST be adapted to 1/2" lines or -8AN lines. Do not reduce the ID to anything smaller. There are some really well built adapters allowing the use of AN fittings directly to the coolant lines so you don't have to use metal lines. What I heard from Karl at USShift was this, "it is extremely important to use the 1/2" lines for the 6R80. Think of it this way, have you ever heard of any auto manufacturer to ever spend more money on a part than needed"?? Why would they use 1/2" lines when 3/8" lines and fittings are cheaper." Good point Karl.

Ford says "who needs a dip stick"? Since it costs money, they were dropped!! Kind of explains why Ford spent the extra money on 1/2" lines-if it's needed, then they spend the money! IF it's not, then don't! lol . To check the trans fluid level you need to get under your rig and in the front passenger side corner of the trans there is a 17mm cap that comes off to reveal a short "dipstick" to show fluid level. The 6R holds appr 12 1/2 qts of Mercon LV. It's full synthetic and isn't cheap at appr $10 qt.

This is one sweet trans. It has smooth, close shifts and offers many driving & shifting options with the 6R controller from USShift that were unheard in earlier auto trannys. I have had 7 different trannys in my same Bronco. A stock 3spd, 3spd w/OD, C4, 4spd toploader, ZF. 4R70w and now my favorite, the 6R. Several of these over the decades were coupled to doublers. But this 6R80 to me is the best trans for a Bronco in all driving situations. The super low first gear, 2 overdrives, close gear ratios, torque converter multiplication that essentially increases your gearing by 2x, compact size, full manual shifting ability, handles amazing power input in stock form, fits our Broncos w/o too many mod's... I like it and hope you do too.

Please check out my build thread that I did here on CB detailing this 6R swap and many other upgrades, go to this page https://classicbroncos.com/forums/showthread.php?t=278607&page=22

and scroll down to Post # 329. There will be more posts, more pics and more unusable information for ya to look at!

Good luck with your 6R80 swap