yakelys69

Sr. Member

- Joined

- Nov 20, 2006

- Messages

- 756

This thread is a spin off rom the "Windsor 5.0 Explorer Motor Wiring with Waste-Spark Coils" in the chat section. Im starting this to help Moddz67 on his installation, hopefully this will be a step by step thread with minimal rabit holes.

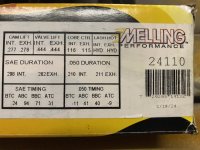

Moddz67 is starting with kit 550-1316 "HOLLEY EFI TERMINATOR X MAX - 2V FORD MOD MOTOR"

* 554-153 Term X Max

* 558-108 Main Engine Harness

* 558-314 Ignition Harness

* 558-209 Injector Harness

* 558-470 Trans Harness

* 558-108 Main Engine Harness

* 558-314 Ignition Harness

* 558-209 Injector Harness

Using the Holley site if you search for each part number individually for the most part you can get the diagrams for that harness. In this case the 558-314 Ignition Harness is included in the 558-108 Main Engine Harness diagram.

The reason to use this kit 550-1316 (or alternatively the 550-1216 if you have a manual transmission) is that it includes the coil drivers needed to make the waisted spark coil packs work. The modular engine used dumb coils rather than smart coils. Smart coils have the coil driver integrated in the coil itself.

It's possible to get this setup to work with 2 wire crank and cam sensors, I don't recommend it, n my opinion and limited experience you will waist hours and it will be unreliable.

To get started you will need a 3 wire crank and cam sensor.

For the cam sensor the solution I used was to purchase a ford cam synchronizer & sensor for 98 5.0 Explorer. The old explorers had 3 wire sensors.

Note: You can't just change the sensor (top) as the synchronizer is different (according to my notes) Also for whatever its worth upto 2008 on the ford 6 cylinder 4.2 the sensor is the same but the synchronizer is a different length.

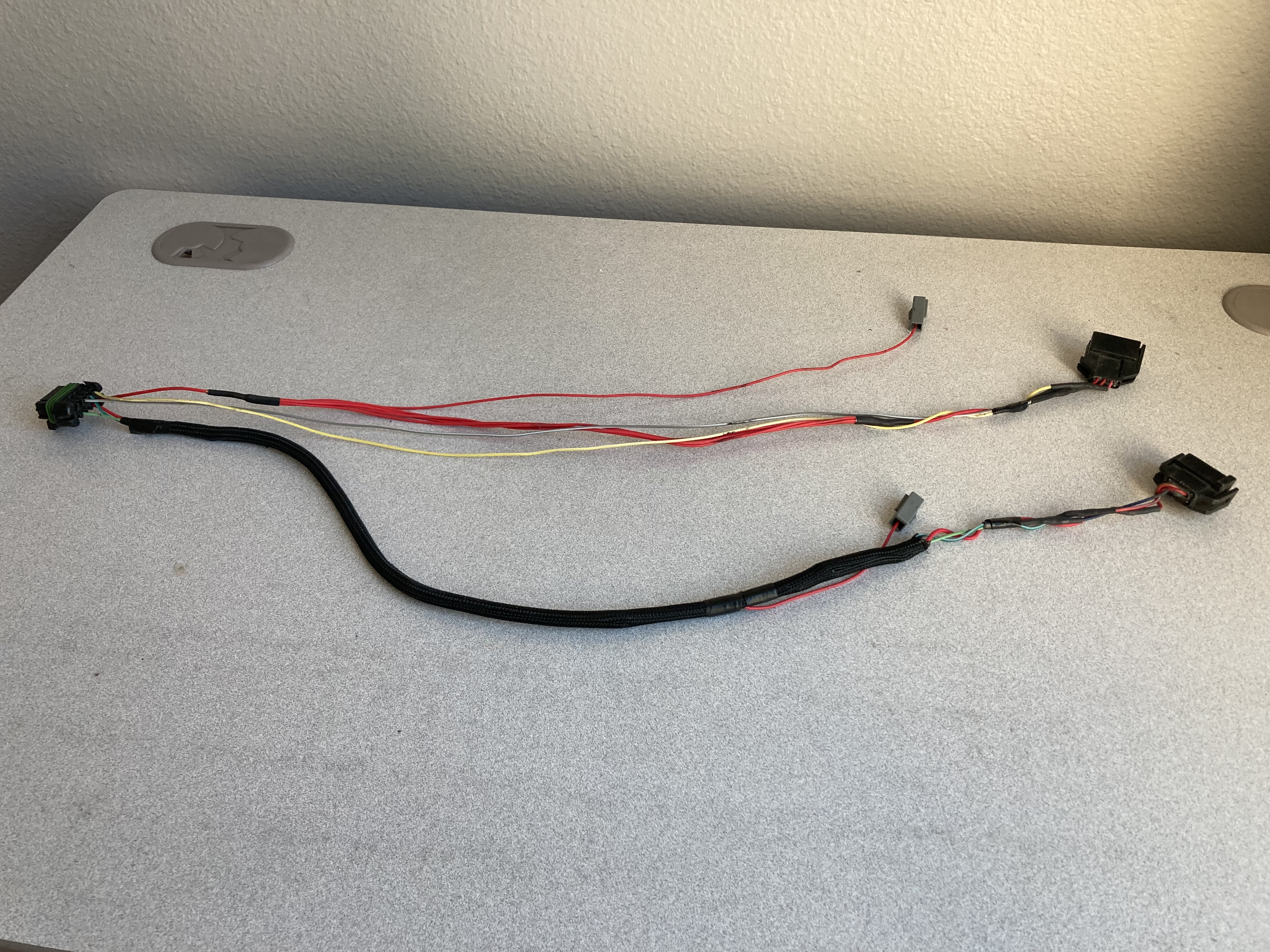

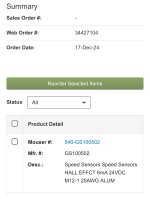

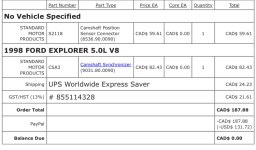

For the Crank sensor you need to obtain a three wire sensor and find a way to mount it, kits probably exist from megasquirt or something but i never looked into it. Holley sells one but I dont know much about that. What I did was Purchase a "Cherry - Gs100502 - Geartooth Hall Effect Sensor." Now it's a "ZF Gs100502". (Part number: ZF Gs100502 or Gs100502 )

I cut the bolt ears off the ford pickup to keep the spacing, then attached an aluminum l bracket to keep the pickup in the stock ford location and retain the timing pointer. paying attention to the clearance from the instructions on the new pickup. Just used whatever was on my bench at the time. Perhaps welding a ridged metal bracket would have also worked fine. See img

Moddz67 is starting with kit 550-1316 "HOLLEY EFI TERMINATOR X MAX - 2V FORD MOD MOTOR"

5.0 Explorer Motor Wiring with Waste-Spark Coils & 4R70W/75W 98+ trans

550-1316 kit* 554-153 Term X Max

* 558-108 Main Engine Harness

* 558-314 Ignition Harness

* 558-209 Injector Harness

* 558-470 Trans Harness

5.0 Explorer Motor Wiring with Waste-Spark Coils & manual transmission

550-1216 kit* 558-108 Main Engine Harness

* 558-314 Ignition Harness

* 558-209 Injector Harness

Using the Holley site if you search for each part number individually for the most part you can get the diagrams for that harness. In this case the 558-314 Ignition Harness is included in the 558-108 Main Engine Harness diagram.

The reason to use this kit 550-1316 (or alternatively the 550-1216 if you have a manual transmission) is that it includes the coil drivers needed to make the waisted spark coil packs work. The modular engine used dumb coils rather than smart coils. Smart coils have the coil driver integrated in the coil itself.

It's possible to get this setup to work with 2 wire crank and cam sensors, I don't recommend it, n my opinion and limited experience you will waist hours and it will be unreliable.

To get started you will need a 3 wire crank and cam sensor.

For the cam sensor the solution I used was to purchase a ford cam synchronizer & sensor for 98 5.0 Explorer. The old explorers had 3 wire sensors.

Note: You can't just change the sensor (top) as the synchronizer is different (according to my notes) Also for whatever its worth upto 2008 on the ford 6 cylinder 4.2 the sensor is the same but the synchronizer is a different length.

For the Crank sensor you need to obtain a three wire sensor and find a way to mount it, kits probably exist from megasquirt or something but i never looked into it. Holley sells one but I dont know much about that. What I did was Purchase a "Cherry - Gs100502 - Geartooth Hall Effect Sensor." Now it's a "ZF Gs100502". (Part number: ZF Gs100502 or Gs100502 )

I cut the bolt ears off the ford pickup to keep the spacing, then attached an aluminum l bracket to keep the pickup in the stock ford location and retain the timing pointer. paying attention to the clearance from the instructions on the new pickup. Just used whatever was on my bench at the time. Perhaps welding a ridged metal bracket would have also worked fine. See img

Last edited: