Community

Buy / Sell

Bronco Tech

3 Arm Wiper Setup

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

Fix Motor Mount

Roll Cage Braces

Throttle Body 65mm

Wheel Alignment

Heat Riser Replacement

Vent Window Repair

Center Console Mount

Straighten Bumper

Ford 6R80 6 spd

More Tech...

-

Welcome to ClassicBroncos! - You are currently viewing the forums as a GUEST. To take advantage of all the site features, please take a moment to register. It's fast, simple and absolutely free. So please join our community today!If you have problems registering or can't log into your account, please contact Admin.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

77 front spindle removal

- Thread starter eslusser

- Start date

- Joined

- Nov 26, 2005

- Messages

- 6,220

- Joined

- Feb 6, 2010

- Messages

- 566

Agree with Apogee the tool with the recessed lugs holds up better.

https://www.wildhorses4x4.com/product/Wheel_Bearing_Nut_Socket/More_Tools

https://www.wildhorses4x4.com/product/Wheel_Bearing_Nut_Socket/More_Tools

garberz

Bronco Influencer

New wheel bearing seals, inspect bearings for excessive heat, repack if they’re ok. Replace if necessary. Do both sides. It’s good preventative maintenance.

Mark

Mark

You do not have to remove a spindle to replace a broken lug bolt. Just remove the hub/rotor assembly, that is where your lug bolts are mounted (from the back side).

Safety 1st. Jack stands, e-brake, tire that came off, under radius arm as back up. Make sure the lock in/out allen head screws heads are very clean, you do not want to strip them. If you do, no need to panic, drill the head off and keep on working. Remove the shaft with vice grips once the lock in/out is off.

Ok so after you take the lock in/out off......FYI this ia a walk thru for my son inlaws 76 Bronco with a F250 low boy D44 axle that the PO cobbed under there, but should be the same as far as taking stuff apart. So bear with me, it also has a 5 lug knuckle swap.

Clean off the outer bunch of grease with spray brake cleaner. There should be a snap ring (a pick and a 90* pick comes in handy here) in the outer edge part of the hub. Use a ratchet strap to keep the hub from rotating as you try to get under it and remove it.

And then remove the snap ring on the end of the axle shaft. Snap ring pliers for that one. Look for a small phillips screw in the inner locking mechanism. Remove it and a gear and spring should come off.....

Next remove the inner locking hub mechanism. You can thread 2 of the lock in/out screws as handles. Then it should come out as an assembly. Depending on your axle and or internal or external lock in/out set up you should have a spring and a large geared ring come off. No worries some one will come along and correct me.

Then yes use ever socket you want, or rented from the parts house that has that tool rental program. I am partial to the old 1/2 drive expose 4 point. Now is the time to take pics and pay attention to how the rest comes apart.

Remove the outer lock nut 1st. Make sure you are pushing straight in with relative force to keep the pins in the 4 grooves of the outer nut.

Once it is loose, thread it off and remove, then use the picks again to remove a washer (with a lot of holes in it) next. Then use the socket again on the inner nut. Once removed, PAY ATTANTION TO WHAT SIDE OF THAT NUT FACES OUT. LOOK/FEEL FOR A SMALL PIN STICKING OUT TOWARDS YOU. Remember that side (with the pin) faces OUT come reinstall time.

With all that removed the hub and rotor should have some play and start to come off, be ready to have the outer bearing come off (in your lap, or on a shop towel), as you pull the hub/rotor assembly off. The bearing races are pressed in the hub and should not come out.

Remove the hub/rotor assembly straight off and FYI the inner wheel bearing is retained in the back side of the hub, by a tap in seal. More on that later.

Tap/hammer out bad lug bolt, install new, carefully tap it a bit to get it started straight, then I stack some washers on the thread side and use a open end lug nut and impact to draw it down and get it fully seated.

Safety 1st. Jack stands, e-brake, tire that came off, under radius arm as back up. Make sure the lock in/out allen head screws heads are very clean, you do not want to strip them. If you do, no need to panic, drill the head off and keep on working. Remove the shaft with vice grips once the lock in/out is off.

Ok so after you take the lock in/out off......FYI this ia a walk thru for my son inlaws 76 Bronco with a F250 low boy D44 axle that the PO cobbed under there, but should be the same as far as taking stuff apart. So bear with me, it also has a 5 lug knuckle swap.

Clean off the outer bunch of grease with spray brake cleaner. There should be a snap ring (a pick and a 90* pick comes in handy here) in the outer edge part of the hub. Use a ratchet strap to keep the hub from rotating as you try to get under it and remove it.

And then remove the snap ring on the end of the axle shaft. Snap ring pliers for that one. Look for a small phillips screw in the inner locking mechanism. Remove it and a gear and spring should come off.....

Next remove the inner locking hub mechanism. You can thread 2 of the lock in/out screws as handles. Then it should come out as an assembly. Depending on your axle and or internal or external lock in/out set up you should have a spring and a large geared ring come off. No worries some one will come along and correct me.

Then yes use ever socket you want, or rented from the parts house that has that tool rental program. I am partial to the old 1/2 drive expose 4 point. Now is the time to take pics and pay attention to how the rest comes apart.

Remove the outer lock nut 1st. Make sure you are pushing straight in with relative force to keep the pins in the 4 grooves of the outer nut.

Once it is loose, thread it off and remove, then use the picks again to remove a washer (with a lot of holes in it) next. Then use the socket again on the inner nut. Once removed, PAY ATTANTION TO WHAT SIDE OF THAT NUT FACES OUT. LOOK/FEEL FOR A SMALL PIN STICKING OUT TOWARDS YOU. Remember that side (with the pin) faces OUT come reinstall time.

With all that removed the hub and rotor should have some play and start to come off, be ready to have the outer bearing come off (in your lap, or on a shop towel), as you pull the hub/rotor assembly off. The bearing races are pressed in the hub and should not come out.

Remove the hub/rotor assembly straight off and FYI the inner wheel bearing is retained in the back side of the hub, by a tap in seal. More on that later.

Tap/hammer out bad lug bolt, install new, carefully tap it a bit to get it started straight, then I stack some washers on the thread side and use a open end lug nut and impact to draw it down and get it fully seated.

Attachments

Last edited:

- Joined

- Jul 1, 2011

- Messages

- 1,868

Look for a small phillips screw in the inner locking mechanism. Remove it and a gear and spring should come off.....

Nice write-up, but there is no screw in my Bronco Dana 44. Maybe it's specific to the F250 Dana 44?

Yea I have a franken-Bronco to deal with at times.

Rustytruck

Bronco Guru

- Joined

- Feb 24, 2002

- Messages

- 10,875

don't draw in the new stud with a lug nut the stress is to high and you risk stressing the stud. support the area around the stud and drive or press in the stud from the back side.

Yes that is the better way of doing things....if you have a press. I used the "support and drive in from behind" method with a HD punch and a 5lb sledge.

And then it seemed like when I was doing the star/criss cross wheel install tightening pattern, that ONE new lug stud was always loose, and always needing more tightening.

And then it seemed like when I was doing the star/criss cross wheel install tightening pattern, that ONE new lug stud was always loose, and always needing more tightening.

Well since finding a bad front axle u joint I figured I would pic document the tear down. Jack and jack stands or jack and then tire under the radius arm for a back up. I use the tire as a safety, since the work floor it gravel. Shame on me I have not been inside this hub in quite a while and it shows.

1. Alan T handle to remove the allen head screws for the Warn lock in/out.

2. Lock in/out removed (soft face hammer tap).

3. Remove axle snap ring (small one) and the large one in the outer rim of the hub. A pick and a small flat tip.

4. One bolt for the brake caliper locking T bar removed.

5. Tap out the locking t bar. drive it IN towards the radius arm.

6. Remove brake caliper. Use a coat hanger to hang caliper from coil spring.

7. Take 4 of the allen head lockin/out bolts and thread them back in the lock in/out. Use them as a handles to get the lock in/out removed.

8. EITHER 3/4 drive hub socket and breaker bar, to break loose the outer spindle nut. Remove it.

9. Use 2 picks to get the washer with all the holes removed. EITHER hub socket and remove the inner nut. Make sure the pin on the nut face, faces you. Clean insp and lay out parts as removed.

11. Grab rotor/hub assembly and remove. Flip it around and you can see the head of the lug studs. Follow thread above advice to replace. Fyi the outer bearing assembly should fall out. You might have a Spring Retainer plate over the bearing.

To get the back seal out (of the back side, that holds in the inner bearing). You just go thru the center hold of the hub and flat tip screwdriver tap it out. Then the bearing will come out. Clean insp and repack. If you were careful you can reuse that seal. othe rwise get new and tap back in place.

1. Alan T handle to remove the allen head screws for the Warn lock in/out.

2. Lock in/out removed (soft face hammer tap).

3. Remove axle snap ring (small one) and the large one in the outer rim of the hub. A pick and a small flat tip.

4. One bolt for the brake caliper locking T bar removed.

5. Tap out the locking t bar. drive it IN towards the radius arm.

6. Remove brake caliper. Use a coat hanger to hang caliper from coil spring.

7. Take 4 of the allen head lockin/out bolts and thread them back in the lock in/out. Use them as a handles to get the lock in/out removed.

8. EITHER 3/4 drive hub socket and breaker bar, to break loose the outer spindle nut. Remove it.

9. Use 2 picks to get the washer with all the holes removed. EITHER hub socket and remove the inner nut. Make sure the pin on the nut face, faces you. Clean insp and lay out parts as removed.

11. Grab rotor/hub assembly and remove. Flip it around and you can see the head of the lug studs. Follow thread above advice to replace. Fyi the outer bearing assembly should fall out. You might have a Spring Retainer plate over the bearing.

To get the back seal out (of the back side, that holds in the inner bearing). You just go thru the center hold of the hub and flat tip screwdriver tap it out. Then the bearing will come out. Clean insp and repack. If you were careful you can reuse that seal. othe rwise get new and tap back in place.

Attachments

Eslusser... I've 50 or 100 of these.

But I'm going to say, If you can find someone who has done 1 or 2 of these. It'd be better to have some looking over your shoulder. Now yes you can do it. Especially if you've done other wheel bearings before. .

But take lots of pictures of How thew pieces are stacked up. . I've been surprised at when I had a actually Ford tech working with me once . He knew how every thing was to fit together. & I'm going to say a lot of what I've taker apart were not really put together correctly the last time some one Packed the bearings.

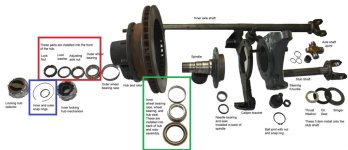

.....Good Luck . & If you can het several of those exploded views they will help also .

But I'm going to say, If you can find someone who has done 1 or 2 of these. It'd be better to have some looking over your shoulder. Now yes you can do it. Especially if you've done other wheel bearings before. .

But take lots of pictures of How thew pieces are stacked up. . I've been surprised at when I had a actually Ford tech working with me once . He knew how every thing was to fit together. & I'm going to say a lot of what I've taker apart were not really put together correctly the last time some one Packed the bearings.

.....Good Luck . & If you can het several of those exploded views they will help also .

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 4

- Views

- 1K