Our classic traction bars are still very popular. We have found that they do a very well with most eb guys. We also sell them to every Bronco year and model as well as Rangers, explorers and many pickups. I have not heard any negative feed back or had a return on them from the result of poor performance. If there was a flaw or a limitation in the design from its intended use and purpose it has not been brought to my attention in the last 2 years. I honestly think this is mostly because we direct a customer to better option like our Torque Tamer when they need more traction control or like to wheel hard.

The classic traction bars will work great for light wheeling and we have had customers running 400hp motors in their eb use them. I personally don't know how well they stand up to 400+ hp. IMO deep gearing kills traction bars quicker than big horsepower. I had a 76 EB with 105 hp to the rear wheels that had 5:13 gears. It ate up my Heavy Duty DIY traction bars in high range on the street. To be 100% transparent I was trying to break them ;D

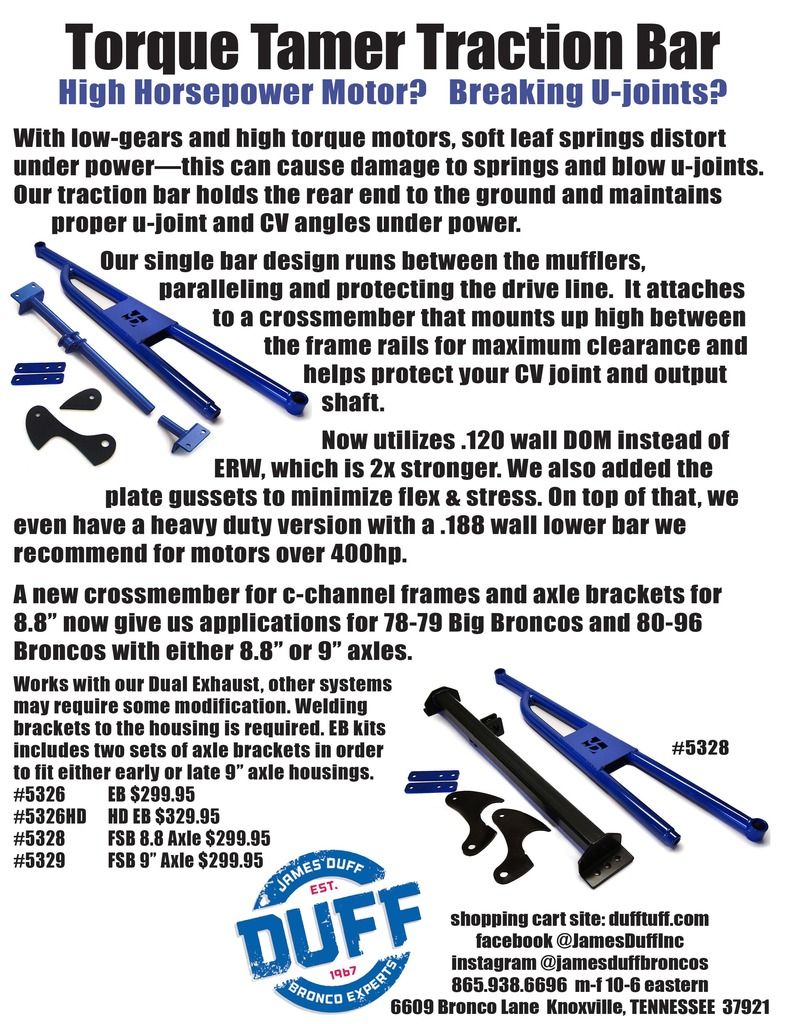

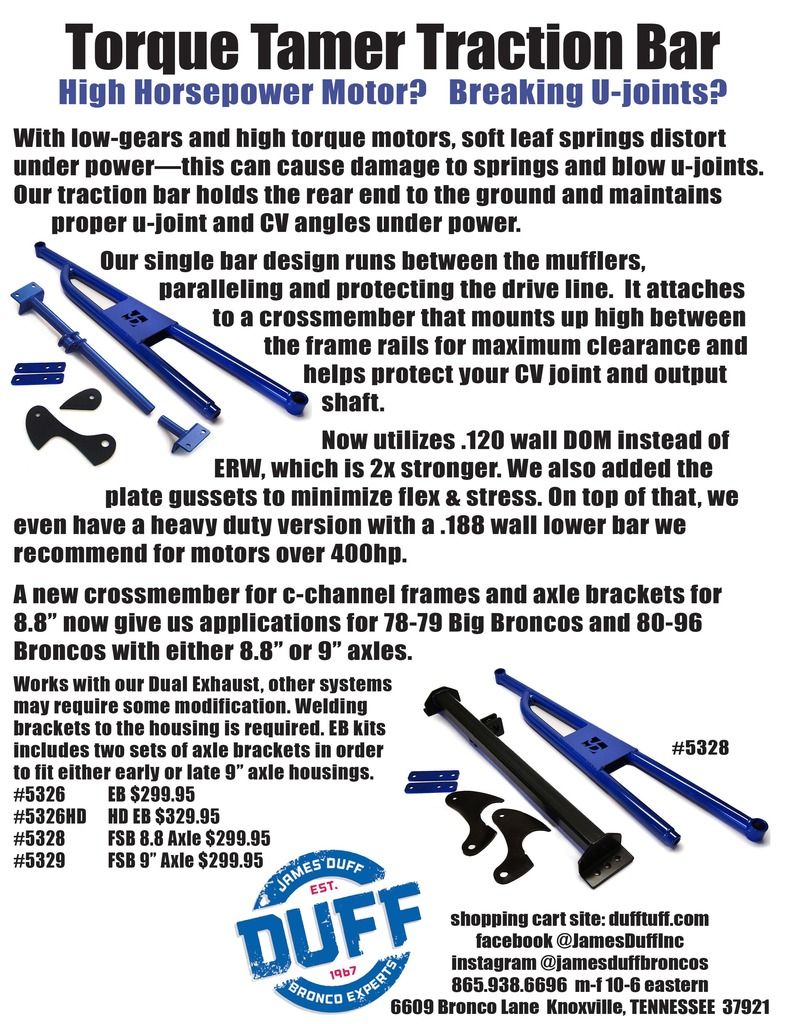

If you need a anti wrap bar that can prevent axle wrap without limiting articulation then our Torque Tamer is a great fit. I've spent a lot of time in the last year making this product better, stronger and now available to to Broncos from 66-96 (not including the B2) and it is now available in an HD version for guys with big horsepower and/or guys who like to play in the rocks. Since the torque tamer came out 15 years ago we saw it was time to make some improvements, a lot has changed. Broncos are getting twice the horsepower, huge tires, deep gearing and going places that would make a Billy goat puke! The new Torque Tamer design is comprised of 100% DOM tube. The main bar and cross member is sleeved in the critical areas for a total wall thickness of .250 (1/4"). I also added a double shear gusset to the main bar to eliminate flex and fatigue. I beefed up the main axle bracket from 1/4" to 3/8" we saw a few guys break the 1/4". I also modified the main fixture and built another fixture that prevents the bars from moving during the weld process. Some customers have struggled installing the main bar to the axle bracket. We eliminated that issue.

When looking at our Torque Tamer vs a similar made DIY kit my research shows that cost is almost the same. Ours is $299 the DIY is $280. Yes there are pros and cons to either way you decide to go. If your building a Bronco with big tires, deep gears and HD axles that is going to get beat to snot on the trails, see a lot of rock damage and you're already a big fan of DIY options then you may need a DIY anti wrap bar. If you're not doing that you may really like a product like ours that is already professionally assembled, welded and powder coated. It's designed for your Bronco so it bolts right in. Our setup only uses one heim joint to allow for maximum articulation. The other connection points are polyurethane bushings to prevent excessive movement and heim chatter. You will still have to weld the axle bracket on but the whole project can be done in a couple hours. Remember if you choose the DIY route this is one of those parts that have to be welded very well. Anti Wrap bars will find the weak link in a big hurry so make sure your welder is dialed in and you are fully penetrating the base metal. One disclaimer I want to point out for any anti wrap bar that runs along side the drive line is exhaust routing may need to be modified. If you use our exhaust kit everything works together.

As always I'm looking for feed back from the community to make our products the best. I hope this explanation better illustrates the value and effectiveness of our product.

Torque Tamer:

http://www.dufftuff.com/Long_Travel_Traction_Bar_1966_77_Bronco_p/5326.htm