Whoaa

Bronco Guru

- Joined

- Sep 26, 2014

- Messages

- 1,059

I'm filling my little brain with gobs of information that I'm suppose to remeber...

From what I have gathered, it's good to use an X pattern when torqueing the front C caps to the Radius arms. My information shows a touque rate of 90 - 110 ft lbs.

And sometimes you'll get "lean" to side or the other, even using diligence when installing new C bushings. And if/when this happens the correction can be a either changing the position of one fo the C bushing, and/or applying a different torque amount to the bottom or top of the C cap.

So taking all of this into consideration is it "normal/common" for the C bushing's to splay open when you start tightening the C cap?

I just installed new C bushing's and trying my best to get them right. I never did get all the way to 90 ft llbs of torque before the caps were nearly touching thier mate on the radius arm, closer to about 70-75 lbs, but the bushings are splaying open...such as things do when "crushed". I'm 100% certain that the bushings are installed corectly w/ the proper orinentation.

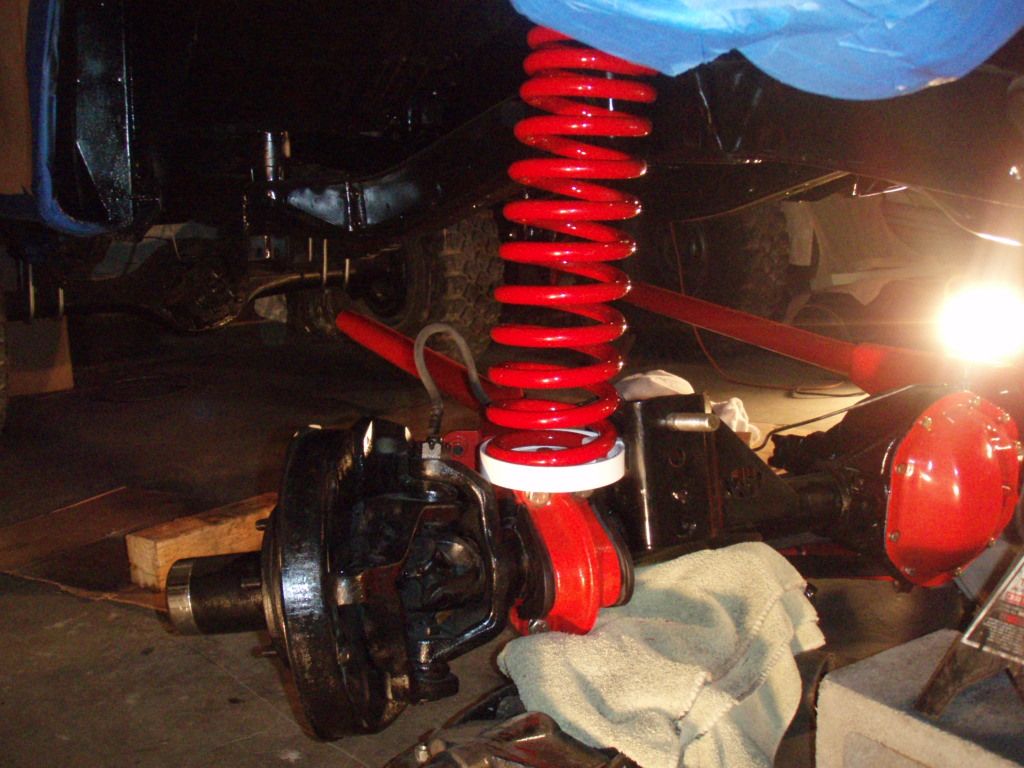

The first pic was for the purpose of a different issue, clerence issues between lower coil cup and trac bar riser, but this pic shows that the housing is pretty close on top. And what it doesn't show is the bottom is touching -radius arm C to the front C cap.

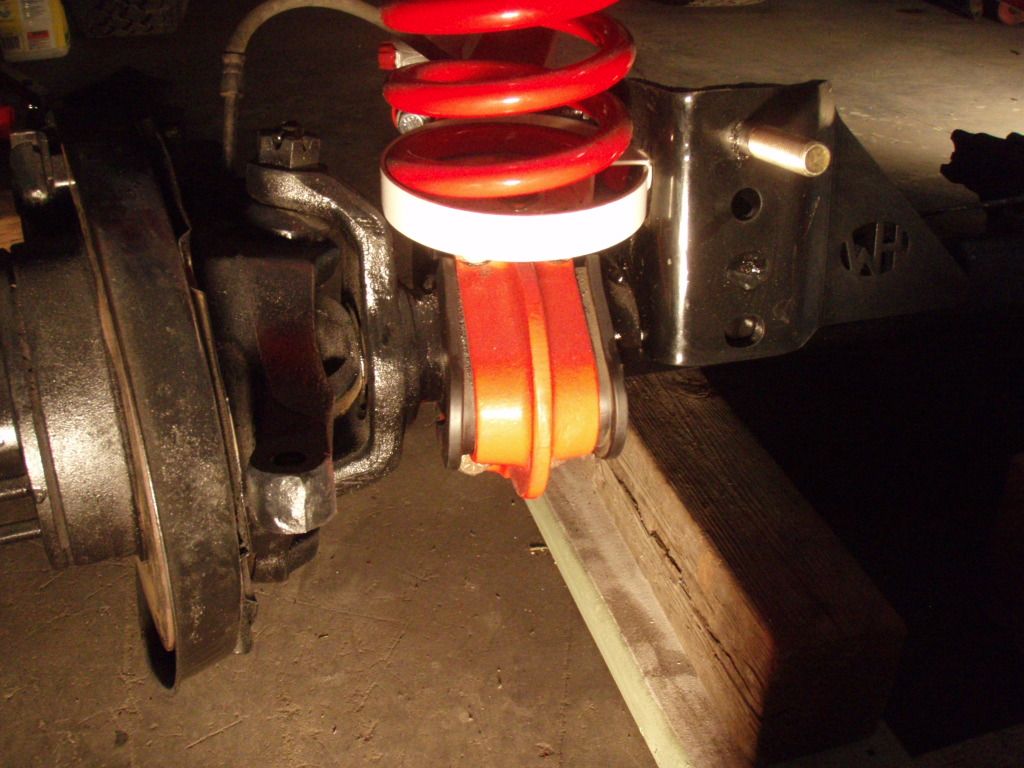

The second pic show the bushing splaying open, but I realize its not the best pic. The bushing ar sticking *out" around 3/8" or so on both sides.

I can get better pic's tommorow from the proper angle..

From what I have gathered, it's good to use an X pattern when torqueing the front C caps to the Radius arms. My information shows a touque rate of 90 - 110 ft lbs.

And sometimes you'll get "lean" to side or the other, even using diligence when installing new C bushings. And if/when this happens the correction can be a either changing the position of one fo the C bushing, and/or applying a different torque amount to the bottom or top of the C cap.

So taking all of this into consideration is it "normal/common" for the C bushing's to splay open when you start tightening the C cap?

I just installed new C bushing's and trying my best to get them right. I never did get all the way to 90 ft llbs of torque before the caps were nearly touching thier mate on the radius arm, closer to about 70-75 lbs, but the bushings are splaying open...such as things do when "crushed". I'm 100% certain that the bushings are installed corectly w/ the proper orinentation.

The first pic was for the purpose of a different issue, clerence issues between lower coil cup and trac bar riser, but this pic shows that the housing is pretty close on top. And what it doesn't show is the bottom is touching -radius arm C to the front C cap.

The second pic show the bushing splaying open, but I realize its not the best pic. The bushing ar sticking *out" around 3/8" or so on both sides.

I can get better pic's tommorow from the proper angle..