- Joined

- Oct 14, 2004

- Messages

- 5,001

Looking at a refresh of my engine over the winter. It's 15 years old with very low mileage but I'm guessing has sucked in too much grit/dirt during that time off road. Still runs like a scalded ape but has blow by and will smoke if you lay into the throttle. I recently picked up a 351W roller block that started life in 1994 bronco that I plan to use with the internals from my current engine. With that said I will need a roller camshaft, lifters, and I'm guessing probably pushrods.

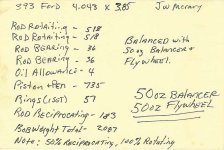

Current engine details from build sheet: (copy & paste)

351W Engine Block(D9AE-6015-ED-18) & Stock 351W Rods

Bored 40 over, honed and prepped with torque plate

Block decked for squareness

Durabond Cam bearings

3.85 stroke crankshaft

ARP rod bolts 150-6004

Stock rods resized

Keith Black KB115 two eyebrow flattop pistons

Clearance Pistons and Block for Crank Throw

Perfect circle rings

King Main bearings

King Rod bearings

Rotating assembly balanced (50 oz Balancer and Flywheel)

Edelbrock RPM aluminum heads with comp cams roller rockers

Edlebrock Performer intake with open 1" spacer

Holley Terminator fuel injection

Holley dual sync distributor (EFI controls timing)

BC Bronco shorty headers with 2in/2 out single magnifllo

Other factors for camshaft selection:

C4 Auto transmission with Transgo Kit, also 15 years old but still performing great.

4.30 gears with D20 Tera Low + Cold Duck doubler

37" tires

My thoughts are to have the 351W roller block bored .040, new cam bearings, and all the prep work done to install the internals from current engine. Obviously replacing all the bearings and new rings. Have the heads checked/done with new valve seals. Plan to ditch the comp cam roller rockers as they are very noisy. I have a set of Trick Flow roller rockers that I hope will be better.

I purposely didn't mention the current cam/specs s thato what is suggested won't have any influence from the current setup. I will say this, it works fine offroad when using lower gearing. On the hwy in 2WD high with 4.30 gearing and 37" tires it has some bog from a standing start that can't be tuned out.

Thanks in advance for recommendations/opinions. I know there have been numerous threads about camshafts but there are not many engines exactly the same. I've emailed a couple of popular Camshaft companies for their input but so far haven't received anything back. Not in a hurry so hoping for several opinions to research and think about before deciding.

Current engine details from build sheet: (copy & paste)

351W Engine Block(D9AE-6015-ED-18) & Stock 351W Rods

Bored 40 over, honed and prepped with torque plate

Block decked for squareness

Durabond Cam bearings

3.85 stroke crankshaft

ARP rod bolts 150-6004

Stock rods resized

Keith Black KB115 two eyebrow flattop pistons

Clearance Pistons and Block for Crank Throw

Perfect circle rings

King Main bearings

King Rod bearings

Rotating assembly balanced (50 oz Balancer and Flywheel)

Edelbrock RPM aluminum heads with comp cams roller rockers

Edlebrock Performer intake with open 1" spacer

Holley Terminator fuel injection

Holley dual sync distributor (EFI controls timing)

BC Bronco shorty headers with 2in/2 out single magnifllo

Other factors for camshaft selection:

C4 Auto transmission with Transgo Kit, also 15 years old but still performing great.

4.30 gears with D20 Tera Low + Cold Duck doubler

37" tires

My thoughts are to have the 351W roller block bored .040, new cam bearings, and all the prep work done to install the internals from current engine. Obviously replacing all the bearings and new rings. Have the heads checked/done with new valve seals. Plan to ditch the comp cam roller rockers as they are very noisy. I have a set of Trick Flow roller rockers that I hope will be better.

I purposely didn't mention the current cam/specs s thato what is suggested won't have any influence from the current setup. I will say this, it works fine offroad when using lower gearing. On the hwy in 2WD high with 4.30 gearing and 37" tires it has some bog from a standing start that can't be tuned out.

Thanks in advance for recommendations/opinions. I know there have been numerous threads about camshafts but there are not many engines exactly the same. I've emailed a couple of popular Camshaft companies for their input but so far haven't received anything back. Not in a hurry so hoping for several opinions to research and think about before deciding.

Last edited: