BBronco

Full Member

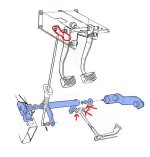

Can someone explain to me, or pictures would be great how this system goes together. I bought the bell crank kit from Tom's and I can't figure out how this goes together.

Also, I do not have the parts that are circled in red in one of the pictures. Where am I able to get them? The piece from pedal to rod, and the bushings for the clutch fork rod.

Thanks in advance!

Brock

Also, I do not have the parts that are circled in red in one of the pictures. Where am I able to get them? The piece from pedal to rod, and the bushings for the clutch fork rod.

Thanks in advance!

Brock