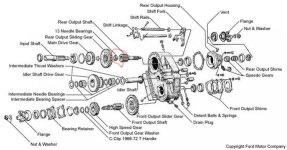

Need help on putting roller bearings back in output shaft. How far do they go in. do they ride on first part of shaft or second. See pictures.

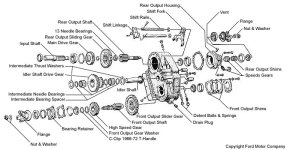

Advice needed. should i have install adapter to transfer before installing to transmission?

Advice needed. should i have install adapter to transfer before installing to transmission?