rednck21

Newbie

- Joined

- Feb 27, 2002

- Messages

- 3,915

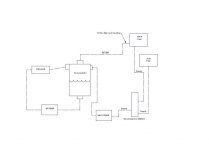

im using two aftermarket tanks, two carter lp pumps, bcb 6 way valve, bcb accumulator, and F250 hp pump. can anyone point me in the direction of a plumbing diagram for this setup?? ive looked and looked, but cant seem to find anything...

also, will 5/16 line be enough for a 331?? ...or should i go with 3/8?

also, will 5/16 line be enough for a 331?? ...or should i go with 3/8?