- Joined

- Dec 5, 2021

- Messages

- 56

Just a little background - I bought a rusted out '73 in 2021 and have been doing a frame off rebuild. I'd never turned a wrench before this project so everything I do I'm doing for the first time. I've done the fab work on the frame, rebuilt the front and rear ends, rebuilt the t-case, sourced a rebuilt AOD, and now I've build my engine and I'm ready to break in my cam. It's been a lot of fun problem solving.

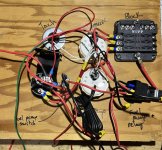

I'm looking for some help with wiring up my run stand. Never crimped a wire in my life before this and I'm trying to avoid a garage fire. What I've got here is pieced together from various youtube examples.

Power from battery to fuse block. This wire has a 30A inline fuse.

1st circuit to batt terminal of ignition switch

2nd circuit to fuel pump on/off switch (Carter P4070)

3rd circuit to fuel pump relay

For the 3 gauges the light bulb wires (white) are combined and then to the batt terminal of the ignition switch.

The ground wires from the gauges (black) are combined and will be grounded to the run stand frame, along with the fuel pump relay and fuel pump on/off switch ground wires.

The ignition terminal of the ignition switch has connections to power the tach, the electric choke on the carb, and the ignition coil.

There is nothing on the accessory terminal of the ignition switch

The start terminal of the ignition switch has a connection to the starter relay.

I have the gear reduction starter from WH and a starer relay/solenoid from summit. The starter relay does not have any markings for the poles, are these directional?

The left pole has a wire to the starter and I need to connect a wire to this pole directly from the battery as well (I think..?).

The furthest right pole has a wire that connects to the starter as well (this is the wire that came with the starter).

I think the pole 2nd from the left that has nothing on it in this image is where I connect the wire from the start terminal of the ignition switch (?)

I think the pole 2nd from the right that has a black wire on it right now either connects to the positive terminal of my ignition coil, or I just leave that pole empty (?).

I’m using a pertronix billet distributor with an igniter 2 module, and an igniter 2 coil.

A couple other questions:

When is the batt terminal of the ignition switch excited? Will the gauge bulbs be on as soon as the battery is connected or will the key in the ignition switch need to be popped to the right?

If you were going to add wiring to this system for a 4g alternator how would you do that? or will it be able to run for the 20-30min break in period with just a charged battery?

I would appreciate some help here so I can get thing fired up!

Thank you

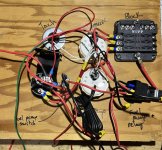

I'm looking for some help with wiring up my run stand. Never crimped a wire in my life before this and I'm trying to avoid a garage fire. What I've got here is pieced together from various youtube examples.

Power from battery to fuse block. This wire has a 30A inline fuse.

1st circuit to batt terminal of ignition switch

2nd circuit to fuel pump on/off switch (Carter P4070)

3rd circuit to fuel pump relay

For the 3 gauges the light bulb wires (white) are combined and then to the batt terminal of the ignition switch.

The ground wires from the gauges (black) are combined and will be grounded to the run stand frame, along with the fuel pump relay and fuel pump on/off switch ground wires.

The ignition terminal of the ignition switch has connections to power the tach, the electric choke on the carb, and the ignition coil.

There is nothing on the accessory terminal of the ignition switch

The start terminal of the ignition switch has a connection to the starter relay.

I have the gear reduction starter from WH and a starer relay/solenoid from summit. The starter relay does not have any markings for the poles, are these directional?

The left pole has a wire to the starter and I need to connect a wire to this pole directly from the battery as well (I think..?).

The furthest right pole has a wire that connects to the starter as well (this is the wire that came with the starter).

I think the pole 2nd from the left that has nothing on it in this image is where I connect the wire from the start terminal of the ignition switch (?)

I think the pole 2nd from the right that has a black wire on it right now either connects to the positive terminal of my ignition coil, or I just leave that pole empty (?).

I’m using a pertronix billet distributor with an igniter 2 module, and an igniter 2 coil.

A couple other questions:

When is the batt terminal of the ignition switch excited? Will the gauge bulbs be on as soon as the battery is connected or will the key in the ignition switch need to be popped to the right?

If you were going to add wiring to this system for a 4g alternator how would you do that? or will it be able to run for the 20-30min break in period with just a charged battery?

I would appreciate some help here so I can get thing fired up!

Thank you