behemoth

Bronco Guru

- Joined

- Jul 2, 2003

- Messages

- 1,736

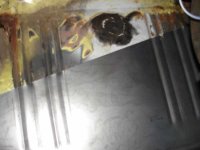

Well I have cut most of the old one out and was test fitting the new panel. There appears to be a fit issue with the panel.

I was thinking about cutting the back edge so that it fits and weld it in place. Now the issue is with the front, now I will have to check to see if it is sitting flat on the floor support.

Also for the front under the pedal any suggestions on welding it, butt weld or lap ?

I would like it to look like it was not there but It is probably to late for that.

I was thinking about cutting the back edge so that it fits and weld it in place. Now the issue is with the front, now I will have to check to see if it is sitting flat on the floor support.

Also for the front under the pedal any suggestions on welding it, butt weld or lap ?

I would like it to look like it was not there but It is probably to late for that.