j.r.nice

Bronco Guru

- Joined

- Feb 8, 2004

- Messages

- 1,615

J.R.Nice,

Can you post any pictures of the flanged sheet metal, especially where the top section is flat? The floor pan replacement should look stock with this method correct?

Thanks for your help

my work is already painted/undercoated over. The Falcon is currently stored off-premise for the winter. I'll see if I can make a piece.

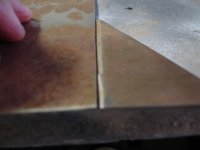

It doesnt look like a butt weld. If you flange the original floor from up top and lay the replacement patch in the flanged area then it will appear stock and flat from up top (inside) The underside looks different than stock, but you will probably be undercoating it anyway.

I'll try to do an exemplar tonight