BroncoBrandon

Full Member

- Joined

- Apr 2, 2009

- Messages

- 243

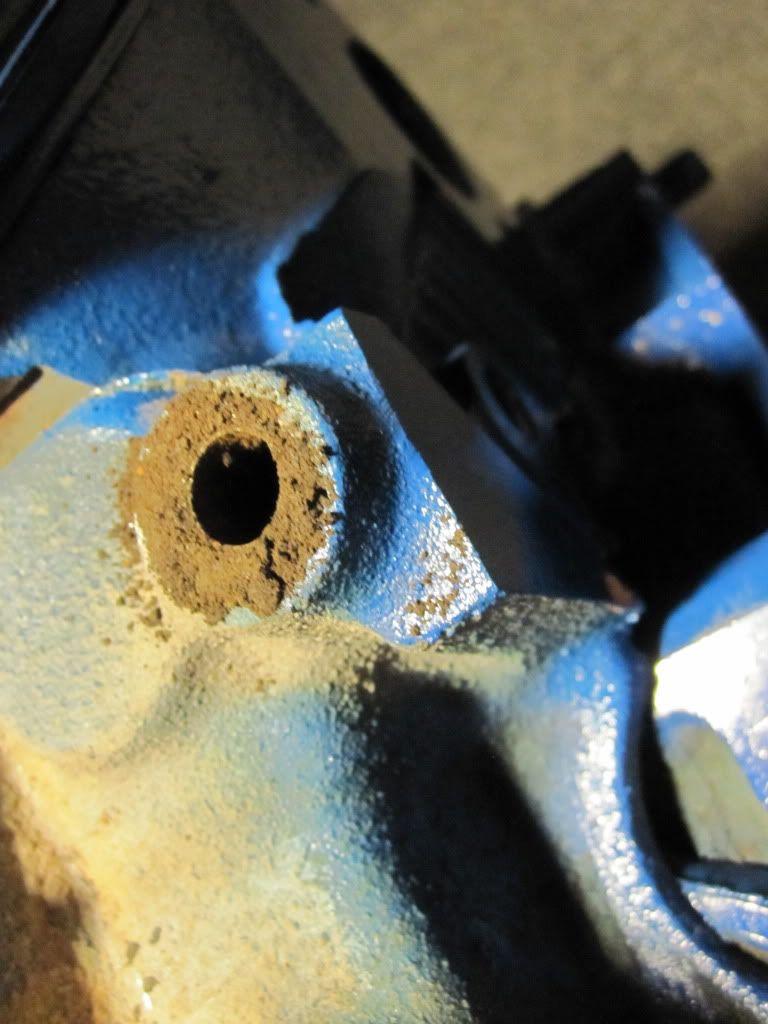

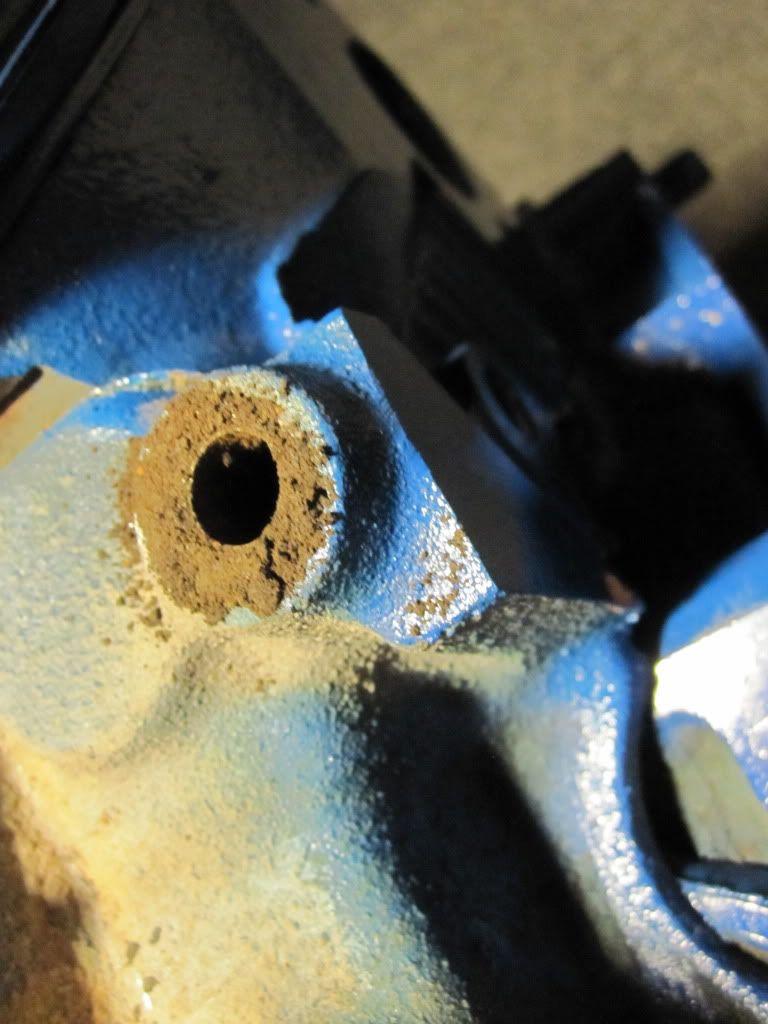

So I was taking the intake manifold off last night and all of the bolts were not really a problem. I did the bolts on the corners last and they were really difficult. as I removed them I noticed that there was some black material that looked like dirt and though it might be a thread sealer that dried up. on the last one, I felt a pop and all it does is spin. It takes allot of force to turn it but it will not back out.

After inspecting the other bolts i noticed that some of the threds in the middle of the bolt were worn down and were caked with the Black dirt type material.. I am thinking that i will have to drill and tap the hole again.

What is the best way for me to approach this task?

After inspecting the other bolts i noticed that some of the threds in the middle of the bolt were worn down and were caked with the Black dirt type material.. I am thinking that i will have to drill and tap the hole again.

What is the best way for me to approach this task?