Greg_B

Bronco Guru

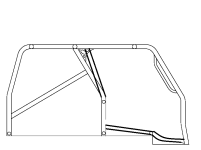

I took the time to draw up the profile of my cage plans... Only thing I left off is a chicken bar... not sure I want one...%)

What do you think? Do the angles look right? Will the bar by the seat be a PIA to get in and out? I can form it differently if needed.

I may laser cut a bucking bronco into that gusset just for kicks...;D

Anything I forgot? Anything you would do differently?

To make sure it clears I formed a mock version up today out of 18ga 1-1/4" tube with all the OD dimensions.... Cheaper than screwing up 2" tube.

Greg

What do you think? Do the angles look right? Will the bar by the seat be a PIA to get in and out? I can form it differently if needed.

I may laser cut a bucking bronco into that gusset just for kicks...;D

Anything I forgot? Anything you would do differently?

To make sure it clears I formed a mock version up today out of 18ga 1-1/4" tube with all the OD dimensions.... Cheaper than screwing up 2" tube.

Greg