ObscureMachine

Seatbelt Orifice Officer

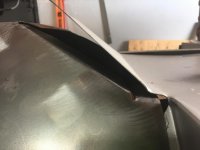

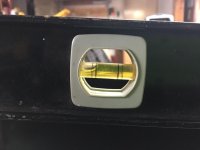

So does Tab A fit into Slot B? Does this tab go OVER the platform "flap", or under it? If it goes under it, what do I do with the gap between the tab and the tunnel. The platform is as forward as it will go, and the tunnel is as far back as it will go.

Thanks for help!

Extra Thanks for Pictures!

- Jim

Thanks for help!

Extra Thanks for Pictures!

- Jim

Attachments

Last edited: