Yep, wrong angle on the driveshaft and WAY too short.

Someone swapped in an existing shaft for something else perhaps. Possibly even a front driveshaft off of one of the oddball '66 models that came from the factory with single-cardan shafts.

Otherwise I don't see anyone measuring that far off since they don't change that much with modest suspension changes. Then again, your measurement indicates the need for a shaft that's a full 2" longer than stock, which is odd in itself.

Maybe you have more lift than you think? Or maybe there is a change in the location of the engine, or transmission from a swap? Or just the difference in the two types of yoke.

The yoke at the transfer case looks like it's been changed to accommodate the type of shaft. The slinger is the wrong size and the gap too wide.

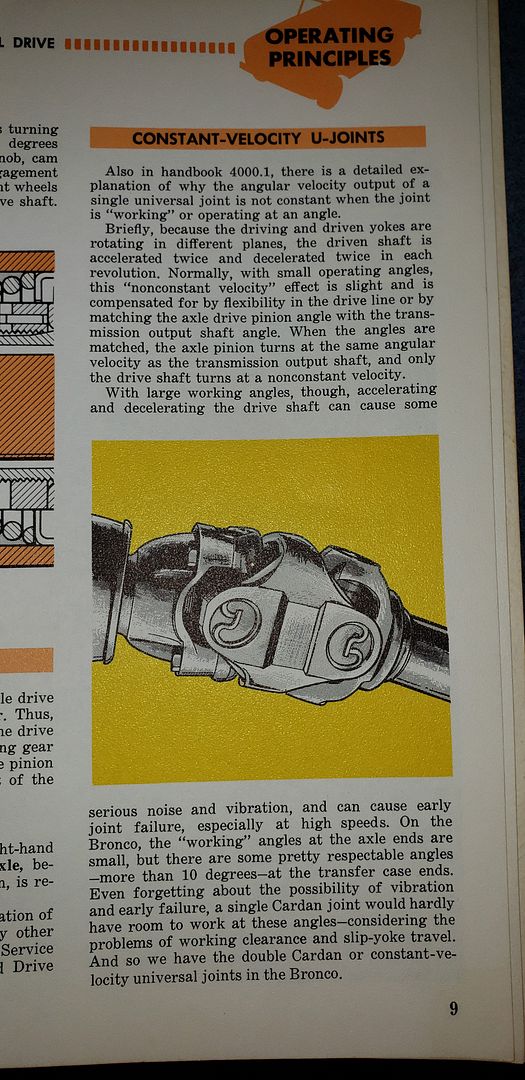

Your rear pinion angle is set up perfectly for a double-cardan shaft. It's improper for a single-cardan shaft like you have, and is potentially why you get the rattling sound. It's a harmonic being transferred from the shaft into the area with the most slop, the gears in the transfer case.

Depending on how long it's been like that too, it could be why you have some slop in your output shaft. It's not like they don't wear out all on their own, but a driveline vibration will certainly accelerate the normal wear and tear.

So, it sounds like you measured correctly, but it's extremely odd to need a longer shaft. I would check the yoke and change it out to the proper style if needed, and then re-measure to make sure. Means more downtime while you experiment, but saves you the trouble of ordering the wrong shaft.

Might as well measure the suspension height while you're under there too. Take a reading between the top of the axle tube and the bottom of the frame rail in all four corners. Anything over 7" in front and 6" in the back is the amount of lift you have. Approximation only though, as it can easily vary by 1/2" or so.

And can you take a couple of shots of the rear springs and if there are tapered shims under them?

Thanks

Good luck. Might be curing multiple ills with one fell swoop.

Oh, did you say what kind of shaft is on the front?

Paul