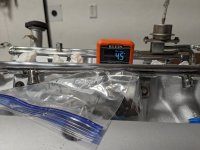

Thanks for the suggestions. After posting the question about the gaskets and bolts. I discovered the Remflex gaskets and bolts in with the exhaust kit. The bolts have the torque lock style washers with them. Wednesday, a co-worker gave me a set of Stage 8 header bolts. So I bolted up the driver side last night. So I will give these a try.I too am a Remflex fan as I see JD is. But there are other factors to insure a long leak free header installation. First is to make sure that the exhaust port surface is clean and flat. Second is to make sure the same is true of the header flange. Test fitting w/o a gasket and checking for gaps between the surfaces is hard to do but necessary. In your current situation, this will be very easy.

For fasteners I only use the ARP header studs. With their fine threaded 12-point nuts, you can get a more even and consistent torque on them.

The key is the maintenance of the torque on the header bolts/nuts. I retorque after the first 2 to 6 heat cycles. Then it becomes a once a week check until finding that I'm not adding anything to them. Then I recheck every oil change. Over time you learn what they want and can retorque as you feel it is needed.

I've followed this Technik multiple times and have zero leaks. My current '96 Bronco has the original header gaskets installed since 2017 and 80k miles. It now has become part of the annual maintenance cycle.

Everything is looking great, and I can't wait to hear it!

If I get more time to work on the Bronco this week I will invite you over. After this week, it will be all about Christmas prep. We are going to our daughter's home for the holidays and granddaughter's birthday.