Ugggghhhh!!!! If you want anything done right you just have to do it yourself. The sandblaster took 6 weeks to get around to my frame. In the meantime after 3 weeks I went to get the differentials and they did the lockers backwards, with the locker in the front and the true trac in the back. It took another 3 weeks to get them redone. To make it up to me they offered to put the brakes on. I wanted to do them myself, but now it's HOT here in AZ so I let them.

Brought everything home. I cleaned up the factory slag and welds on the frame with a sanding disc for a neater appearance. For the frame I decided on KBS coatings 3 stage frame system. I know a lot of people like to powder coat, but once you powdercoat, you can't change anything. If you remove part of the coating to add a shock mount or something, it'll peel off everything around it eventually. I like having the option to modify in the future. The system was easy to do: apply a diluted zinc compound with a sprayer (I used a weed sprayer instead of the bottles they provided), rinse, then brush on the primer. The primer is UV sensitive so if it's going to see sun, it needs a top coat. While the frame mostly won't see direct sun, I put a top coat on anyway. Then a residual problem from the sandblaster. Because he took 6 weeks, the air temp now tops out ABOVE 85 degrees in the afternoon, and the primer requires 4 hours to dry tacky and any topcoat within 6 hours of application or you'll have to sand it before you can add the top coat. Even though I started early in the morning, by the time I could put the top coat down, it was hot. I added reducer, but the final coat shows some brush lines and some drips. The primer coat was perfect and looked beautiful because it has low surface tension and flows to a nice, even, flat coat. The Top coat wouldn't flow the brush marks out, yet ran on the vertical surfaces. Not too bad, but damn it, It WAS perfect. Once this stuff is on, the only way to take it off is a grinder so I'll have to live with it. If I do it again (and I will with the underside) I won't brush such a large area. I'll spray it.

The differentials came back. I used Chrome moly on the front and some Yukons on the back, upping the 29 spline to I think 31 or 33 (can't recall now). Also upgraded the bearings.

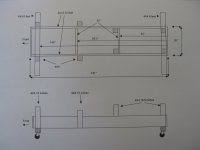

I chose a WH 2.5 inch lift kit. Partly because I didn't want to modify everything to go higher, and partly because I'm also doing a 1 inch body lift for the NV3550, 33 inch tires, and it needs to fit through the garage door with the top on. Since I'm not going to be crawling, I didn't see the need to go higher. I guess I'm just part of the "camping" crowd as their website states. Poly bushings except the radius arm to frame which is rubber. I upped to 7 degrees for the "C" bushings and use their 6 degree wedge for the back springs. I splurged on their Extreme U bolt kit. I couldn't get the metal sleeve out of the rear shackle so I took it to a machine shop. They couldn't either so I had to get new ones. Picked up a BC Bronco 23 gal tank, and bolted it all together. I'll torque it to correct specs after the new engine is in and it settles.