Welcome to the club. Just finished my 347, delivery from machinsist this AM.

Edelbrock performer heads, 60cc volume, KB 366 stepped hyperT flatop pistons, SCAT stroker forged crank/ rods. To use the pistons I wanted, I had to pick different scat components so a little more cost than a kit.

My camshaft from fordstroker.com who I highly recommend:

J. DIAM: STD INT EXH

VALVE ADJUSTMENT HYD HYD

GROSS VALVE LIFT .561 .556

DURATION @ .006

TAPPET LIFT 260 270

VALVE TIMING OPEN CLOSE

@ .050 INT 3- 33

EXH 45 7-

SPECS FOR CAM INST. @ 108.0 CENTERLINE

INT EXH

DURATION @ .050 210.00 218.00

LOBE LIFT .351 .348

LOBE SEPARATION 112.0 FIRING ORDER STD

ROCKER ARM RATIO 1.60 1.60

Cam is a fordstroker design, compcams grind.

Cam installed advanced two degrees to drop RPM range, have not test driven it but by all accounts the way it starts right up and throttle response is fabulous.

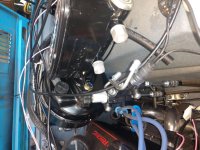

I'm using a custom ignition system designed for this cam/motor, by Ignition Engineering. They used the shell of a Duraspark, set the curve to my cam/motor use, and limited advance to prevent detonation and piston issue (max 38 degree's), using a mopar ignition module which is cheaper than a Ford duraspark and reliable as the day is long in Phoenix summer heat.

Carb is a new out of the box Holley TA 650, no adjustment needed. I'm going to get a AFR reading once its insalled in vehicle.

My stroker lessons learned:

Don't be to afraid about pushing 9.8:1 CR, with the right cam and aluminum heads, dynamically the motor will be seeing about a CR of 8.5:1You'll only get into trouble if you fall for a cam thats too big.

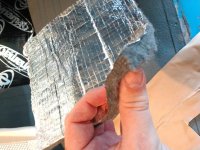

You already found one, ensure all the oil galley plugs are tapped, forgot one and on first start lost oil pressure. The plugs don't like to be cleaned in a abrader, loosens them up.

Second lesson, every cam maker except fordstroker wanted to give me too big a camshaft, all worked from 1500 rpm on up. Compcams technicians one on one wanted to tighten up the LSA which would work counter to my goal (heavy truck, relatively hi CR, lower power band, excellent idle and vacuum).

Stay with a stock oil pump, last thing you need is hi pressure oil flying around inside finding an excuse to burn, stock pump gives me 60 psi at idle.

Classic rear end oil leak, two to be exact. First was standard rear intake leak, easily fixed, second hard to find, rear main seal, needed to buy the upgraded seal to get it to stop leaking. Not sure of that part number, sorry.

My recommendations: Make sure the cam works with your stuff, I spent four weeks going back and fourth with three cam designers before locking down this one. I was also going to try and fake it with an EFI camshaft (i thought I might be goint that way), but now satisfied I made the right choice sticking with a carb cam.

It sounds like you have EFI? If so, I highly recommend getting it to a tuner and solve your higher RPM issues once it gets running, at least verify AFR so you don't smoke the pistons. If your using hypers, stay below 32 degrees advance.