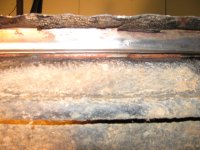

Ok, got back into the shop and finished getting my passenger fender removed. I have taken many photos. I have read other post where guys said they cut a couple of spot welds and the fender fell out. Well that was not the case with mine. I do not know if the fenders were attached differently over the years. Mine is a 66 wagon, and I can only share with you my experience. Also keep in mind that I was very careful and worked slowly to make sure that I did not damage any of the surrounding metal. On my previous post where I said to cut around the edge, try to cut down to maybe an inch of the edge. This will allow you greater access with the angle grinder and wire brush. My orig plan was to use my portable sand blaster to clean metal to locate welds, but it was raining heavily last night and I could not roll Flying Tiger outside. I worked with the rear tire still on, you could of course take the tire off for more room to work. My first job was to thorouly clean the inner edge of the remaining fender. You need to really get in there and get down to the bare metal, this will make the spot welds easier to see. First pic is all the equipment that I used. After I finished removing the fender, I counted 57 spot welds, thats right, 57. Once the metal has been thoroughly cleaned, and the spot welds located, you need to center punch each weld. This step is very important and can save you time later. I used both a deck screw and a ground down phillips screw driver as my punch. On hind sight, I think a better option would be a drill and a small bit. You really want a good pilot hole because the spot weld removing bit is going to want to travel and walk. To save you time of constantly trying to reset the bit on the spot weld, take the time to make a good center punch or drilled pilot hole. Next picture is the bit I used. I bought the 3/8 bit at Harbor Freight. Cost was under $5. The bit has a center point which is spring loaded. There is a screw on the end of the bit that allows you to adjust the tension of the spring. The bit is actually double ended. You can screw the bit off and turn it over for a fresh set of teeth. I cut all 57 welds without turning it over. The first pictures you see of holes being drilled is on the rear bottom portion of the fender edge. I started on the bottom and worked my way up. There are later pics that show how you can clearly see where the spot welds are. The last pic on this page you can see where the fender goes behind a lip. About a foot up from the bottom the fender goes behind a lip. I only found a couple of spot welds on the front of that lip. The rest of the welds in this area of the fender are actually welded from the rear light bucket housing. I could not get to those with the spot weld bit. Those were removed using a combination of the air chisle, hammer and chisle, and the angle grinder with a cutting wheel.