Well, thanks to EFI Guy I've got a bunch of work going on-

I've been piling up parts for awhile and I finally jumped on it and had him burn a chip so I could get the most out of my parts.

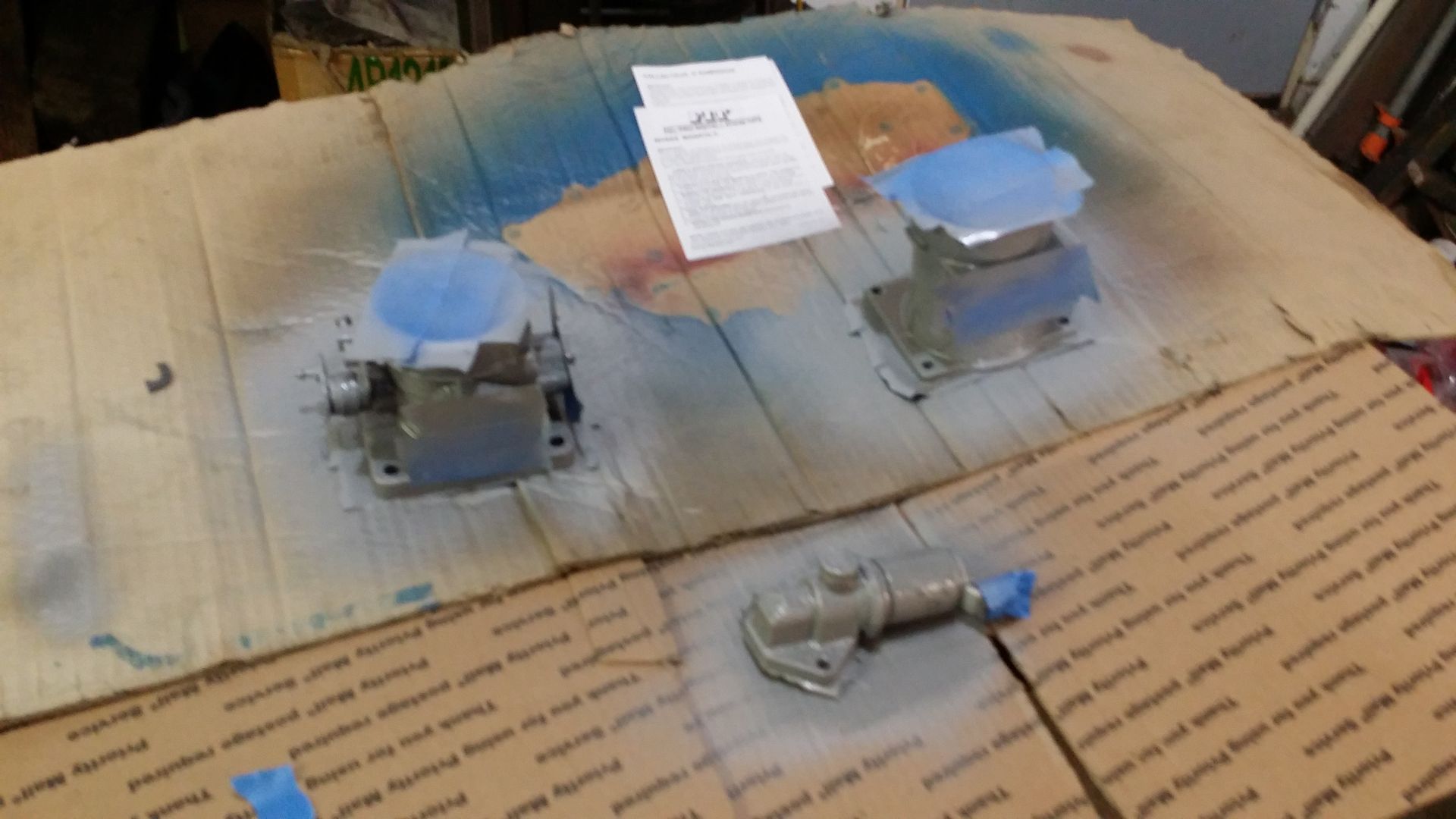

I tossed a coat of paint and clear on my Chinese speed parts (no clear on upper in this pic)

I tossed the computer in the Bronco and drove it up to the house - runs completely different, starts and gets to idle much faster now. It loops a little, but I've got the MAF unplugged as I need to switch over to the Explorer MAF we tuned for. To be expected - motor is cold.

[youtube]LOk0H-MUgIk[/youtube]

Last pics of this setup-

So of course the bolt snaps right off trying to pull the IAC off the throttle body... %)

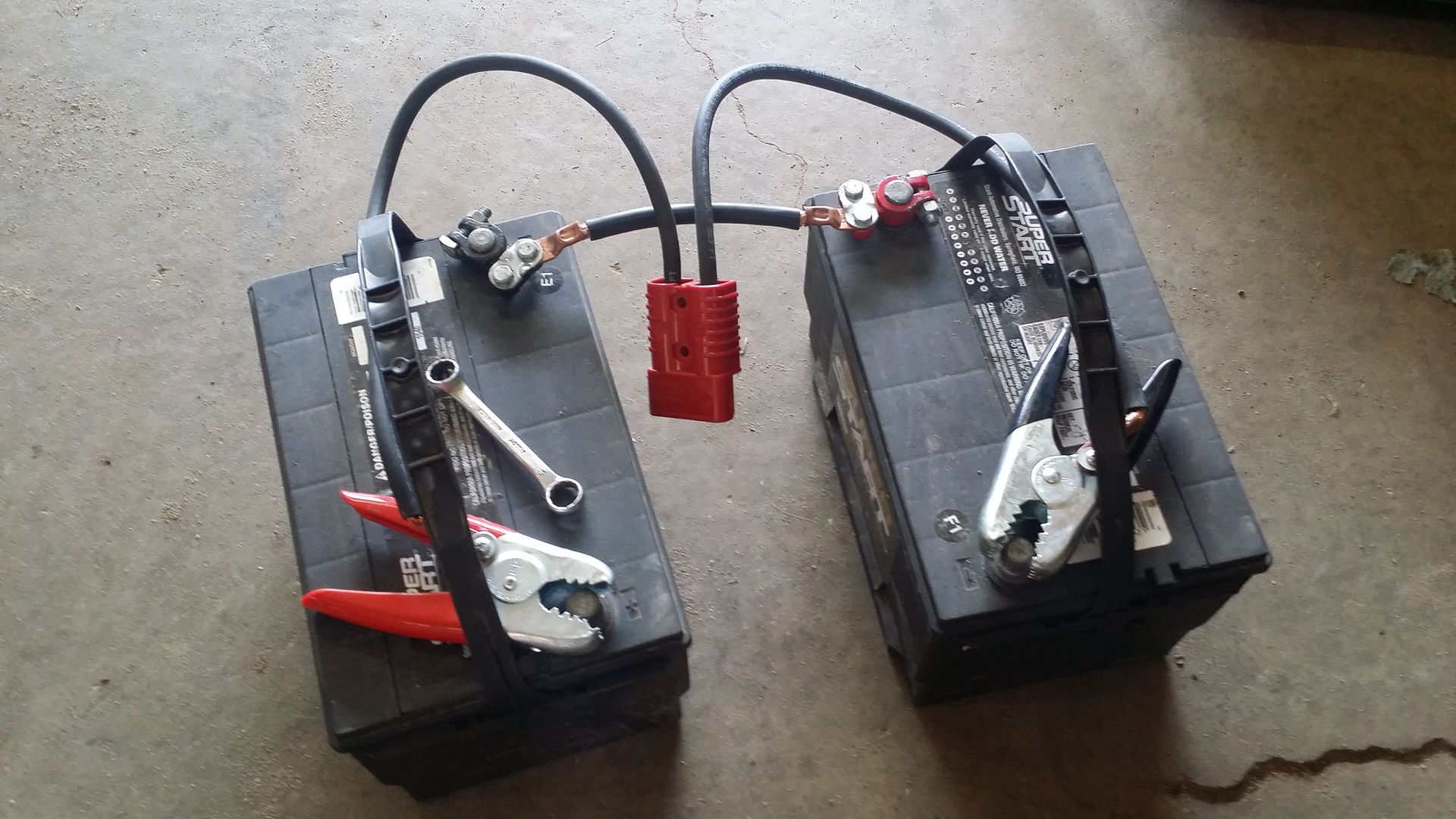

I don't have a 220v welder but I do have a lot of truck batteries....

Out comes the Ready Welder and I literally touch the nut with the wire and it instantly fills and turns the nut cherry red. I love amps!

Unbolt more parts-

#1 plug looks great - these are the plugs I put in this when I built the engine.

Make a giant ass mess- clean said giant ass mess. Cover it in goo

Take the dirty wiring and injectors off your old intake and put it right on the fresh Chinese speed part. Make studs out of bolts - test fit intake gaskets - forget that the driver's side front corner needs to be much longer and have to pull the intake back off....

I just stuck the intake on there for fun and notice that there is an extra intake bolt that doesn't line up - not worried about it.

Hope this crap is dry enough to put together in the morning-

It looks like I'm going to need a MAF adapter for that throttle body. I'm going to put a new radiator in it just for fun - this is a junkyard unit I had meant to replace some time ago. I have to get a new gasket for between the intakes as the provided gaskets look like dirty conveyor belt material. Most importantly I need to hit up a junkyard and get the plug for the MAF so I can get it running right. I'm hoping to get this buttoned up tomorrow so I can start test fitting my headers - time to make some sweet Windsor music ;D

I'm going wheeling next weekend - I ordered u-joints so I can rebuild my front drive shaft. I'm really looking forward to this as the last two events I had fuel issues and I got that fixed just before I started this project.