Tech article by Chris (taipeichris)

Since I’ve owned my 1966 Bronco it never got past 3rd gear for years and I drive the freeways in Los Angeles all the time.

Finally I collected the parts to install my new NV3550 and a twin-stick shifter I purchased made for an early Bronco.

The problem simply was the twin-stick shifter wasn’t designed with the offset of a NV3550 in mind. With the mounting bracket of the twin-sticks, the bracket supplied by Advanced Adapters, and the height of the shifters I could see it wouldn’t work.

I wanted to have a clean twin shifter that would not be killing my right knee all the time and cleared the shifter from the NV3550. Additionally I wanted to close the whole in my floor where the 3speed shifter was previously installed. So I decided to design and fabricate my own shifters and a sheet metal floor patch or access panel which would allow me to install a stock carpet kit one day. After all these are just two levers on a common pivot point, right?

Parts and Supplies Needed:

I didn’t like the way prefab tubing fit; it had too much play. Instead I took solid metal rods and drilled them to make snug fitting tubes for my pivot points.

Including machine shop expenses and materials my total spent was just under $80 not including tax or shipping.

Fabricating The Floor Patch.

1. Measure the whole in your floor that needs to be covered.

2. Cut out a large piece of paper from a grocery bag. Making sure your lines are square, draw the outline of the patch to make your template. I added a 3/4 inch tab on the edges to allow for the tabs to make a physical connection over the existing floor. I also labeled the template to show front and top.

3. Double check your measurements, measure twice, cut once. With that said, cut out your paper template and fold it to match the different angles of the floor. When you are satisfied with your paper template carefully trace it onto your sheet metal. For my patch, I used a scrap piece from an old hard top.

4. After double checking your measurements, cut out your sheet metal patch. You can use a cut off wheel on a grinder or sheet metal sheers. I prefer to use my electric sheet metal sheers from Harbour Freight.

5. To make my bends I have several pieces of extra metal bar around the garage I use to bend my sheet metal patches. Here I clamp the first bar under the patch with two vice grips at each end. Next I clamp the other bar on the top side of the tab which I am going to bend down. I couldn’t find my extra vice grips so I just used a channel lock instead and slowly bent my first tab.

6. Check your bends often during this process. Bend the patch carefully and make sure you apply even force to keep your bends straight. This takes a bit of back and forth work to check each bend as you go.

7. With the bends completed, try a test fit. At this point the big whole in my tunnel was completely covered.

8. Sand, paint or coat the patch to match your floor. I Herculined my floors so I did the same to the patch and let it dry. Later on you will be removing a portion of your new patch for the shifters to come through the floor so you may want to wait to paint the patch until the end of this project.

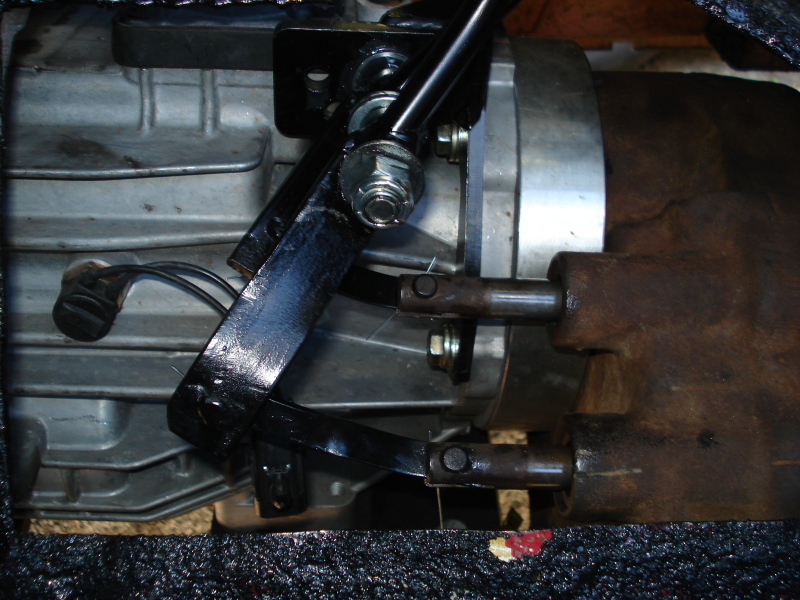

1. The first thing to establish here is what transmission you are using and does it come with a mounting bracket for the 4x4 shifter. In my case Advanced Adapters provided this backing bracket with the NV3550 kit. All I needed to do was drill a 7/16 diameter hole in the center for the pivot point of my shifters. For you, you may want to fabricate a bracket of your own depending on your transmission. A simple solution is a flat metal bar with 3 holes drilled into it. [The correct length will vary depending on your application.] Your mounting bracket will require two outer holes to be drilled for mounting the shifter to the transmission and one hole drilled in the center to mount the pivot point for your shifters. With my setup I drilled a 7/16 hole into the center of the bracket supplied by Advanced Adapters. I then welded the 7/16 course thread 4 ¼ inch grade 5 bolt used for the pivot point. Later this 7/16 bolt was trimmed to the exact length required.

2. With my high quality napkin and tin foil I made 2 bendable templates for the upper rods of the shifter. I started by rolling the foil with the napkin in the center and then cutting the foil rods into two 12 inch length.

My goal here was to first shape the rear axle shifter then the front axle shifter. I wanted to have the end result to allow clearance for the two shifters to be able to move freely with out binding up when the shifter knobs were installed. Also I wanted them to be low enough to allow for full shifting of my NV3550 shifter in all gears and for clearance to my left knee to not hit at all. Last but not least the ending product had to be able to fit under my sheet metal patch for the floor. Easier said than done.

3. With the mounting bracket installed onto the transmission I next installed two 1 ½ inch long pieces of drilled metal rod onto the pivot bolt. The shifters and lower arms will later be welded to these with washers and a lock nut.

4. I designed the rear axle shifter to be in 2 wheel high when the shifter was in a low position on the floor with the shifter knobs both being at an equal height when in all positions. Forming the foil rod here took some practice, imagination for future clearance, and some trimming. At this step I marked on the inner tube with a Sharpie the position of the foil rod and drew two alignment lines from the foil rod to the tube.

5. I repeated this step for the front axle shifter. To make sure I was going to have the desired end result I had a flat piece of card board I used to cover the large tunnel hole to represent the sheet metal floor patch. I trimmed a small hole in the card board allowing for the foil rods to poke up through the floor.

I used a small amount of blue masking tape to hold the shifters in place at times while I shifted the foil rods through all positions.

6. To bend the metal rods I strongly recommend you cover the threaded end of the rod with a lot of making tape. Don’t screw up the threaded ends of the rods. Start from the top of the rod and make your way down. This helps to protect the threaded end from accidentally being crushed when using the long pipe/breaker bar to bend the rod.

7. Starting with the first bend, compare the foil rod to the metal rod marking on the metal rod a line where the first bend is to be done. Carefully place your metal rod in one side of your vice, the foil rod in the middle, and a small 1 inch piece of scrap metal rod on the left side in the vise. Line up the mark on the metal rod with the edge of your vice, place your long pipe/breaker bar over the metal rod and slowly bend.

This was tricky and very time consuming. You will do step 7 over and over before achieving the correct shape of your metal rods.

8. You may want to cut the non-threaded ends of the shifters to the correct length for your application. This will very depending on your body lift height. Try to contour the end of the rod with the grinder so it will fit over the pivot point metal tubes.

9. Tack the rods into place but do not weld them completely just incase you need to reposition them later.

10. With the rods tacked in place, remove the protective tape from the threads and mount your shifter knobs. Try moving them freely, imagining where you want the final location of 2 wheel high and 2 wheel low to end up.

11. At this point I found the metal tubes could be trimmed allowing the shifters to be installed closer together. I trimmed them just a little at a time, installed the 7/16 washers, and the lock nut loosely.

12. Cut two pieces of the 1 metal bar, a 3 inch, and a 4 inch piece. Cut out a shape with two long outer finger which fit over the metal tubes at the bottom of the pivot(See the parts photo). The rear axle arm will be somewhat shorter than the front axle arm. Grind out a slight angle on the inside of the bar between the fingers.

13. Drill a ¼ inch hole about ½ an inch away from the end of the two bars. Take some time to view the movement of the arms under the metal tubes. When I got the angles right here I tack welded them into place.

14. Cut two pieces of ½ inch wide card board strips. These will connect the bottom of your shifter arm to the transfer case rails. At this point the length will vary. The rear shifter connection bar was about 3 inches and the front shifter connecting bar was almost 5 inches long. Your exact length will vary. (The pair in the photo were too short, I made another set) Double check the movement with the card board connecting bars first. Next cut to length your metal bars and before you start to do any bending, drill 2 ¼ inch holes at the ends of each.

15. To bend the lower arms of the shifter I placed it in the vice and used a large adjustable crescent wrench to make my final adjustments. Keep the bends in the middle of the bars not at the ends. The ends will require flat surfaces for the connections at the clevis pins to move freely. Also some twist will be needed to make the connection rods move freely. Try assembling the shifter and moving it check to make sure it doesn’t bind up.

16. Cut the clevis pins to length and welded them into place on the lower arms of the shifter. At this point I did my final welding making it very solid.

17. Paint. I filed the metal tooth marks from my vise off, cleaned the metal with acetone, masked off the threaded ends and gave the shifters 2 coats of semi-gloss black paint. I also prepped and painted the sheet metal screws too.

18. Finally I installed the twin-stick shifters, trimmed the sheet metal floor patch, and installed the patch, and shifter boot. The trim ring did also need some adjusting to make it fit flat on the floor.

After all said and done I am very happy with my ending result. If anyone has questions please feel free to contact me.

Chris taipeichris13@yahoo.com

Since I’ve owned my 1966 Bronco it never got past 3rd gear for years and I drive the freeways in Los Angeles all the time.

Finally I collected the parts to install my new NV3550 and a twin-stick shifter I purchased made for an early Bronco.

The problem simply was the twin-stick shifter wasn’t designed with the offset of a NV3550 in mind. With the mounting bracket of the twin-sticks, the bracket supplied by Advanced Adapters, and the height of the shifters I could see it wouldn’t work.

I wanted to have a clean twin shifter that would not be killing my right knee all the time and cleared the shifter from the NV3550. Additionally I wanted to close the whole in my floor where the 3speed shifter was previously installed. So I decided to design and fabricate my own shifters and a sheet metal floor patch or access panel which would allow me to install a stock carpet kit one day. After all these are just two levers on a common pivot point, right?

Parts and Supplies Needed:

| Quantity | Parts Description | Cost |

| 2 | shifter knobs | $12.99 each |

| 1 | shifter boot w/chrome ring | $24.99 each |

| 2 | ¼ diameter by 12 inch long round rods | $3.31 for 3 feet |

| 1 | piece of 1x3/16x12inch metal bar | $2.30 per foot |

| 1 | piece of 1/2x1/8x12 inches long | $1.30 per foot |

| 1 | ½ diameter 3 inch long round rod | $0.60 |

| 1 | 7/16 course thread 4 ¼ inch grade 5 bolt | $1.21 each |

| 1 | 7/16 lock nut | $0.27 each |

| 2 | 7/16 washers | $0.10 each |

| 2 | 1/4x2 inch clevis pins | $1.29 each |

| 2 | 3/32x1 inch cotter pins | $0.19 each |

| 4 | ¼ inch washers | $0.05 each |

| 1 | 8-18round washer/phillips sheet metal screws | $2.59 per box |

| 1 | long piece of tin foil | Cheap |

| 1 | restaurant napkin | Free |

| 1 | semi-gloss black Rust-O-leum spray paint | $2.99 |

| 1 | paper shopping bag | Free |

| 1 | medium size piece of card board | Free |

| 1 | medium size piece of sheet metal | Free |

| Tools Required | |

| 1 | very big vice |

| 1 | long metal pipe/breaker bar(for bending the shifters) |

| 1 | big crescent wrench |

| 4 | vice grips |

| 1 | drill press |

| 1 | electric grinder with a cut-off and grinding wheel |

| 1 | electric sheet metal sheer [optional but handy] |

| 1 | 7/16 drill bit |

| 1 | ¼ drill bit |

| 1 | socket set |

| 1 | wrench set |

| 1 | roll of blue masking tape |

| 1 | sharpie marker |

| 1 | pair of scissors |

| Machine Shop Expenses | |

| Threading the metal rods | $15.00 |

| Drilling the solid metal rods to make metal tubes | $5.00 |

Including machine shop expenses and materials my total spent was just under $80 not including tax or shipping.

Fabricating The Floor Patch.

1. Measure the whole in your floor that needs to be covered.

2. Cut out a large piece of paper from a grocery bag. Making sure your lines are square, draw the outline of the patch to make your template. I added a 3/4 inch tab on the edges to allow for the tabs to make a physical connection over the existing floor. I also labeled the template to show front and top.

3. Double check your measurements, measure twice, cut once. With that said, cut out your paper template and fold it to match the different angles of the floor. When you are satisfied with your paper template carefully trace it onto your sheet metal. For my patch, I used a scrap piece from an old hard top.

4. After double checking your measurements, cut out your sheet metal patch. You can use a cut off wheel on a grinder or sheet metal sheers. I prefer to use my electric sheet metal sheers from Harbour Freight.

5. To make my bends I have several pieces of extra metal bar around the garage I use to bend my sheet metal patches. Here I clamp the first bar under the patch with two vice grips at each end. Next I clamp the other bar on the top side of the tab which I am going to bend down. I couldn’t find my extra vice grips so I just used a channel lock instead and slowly bent my first tab.

6. Check your bends often during this process. Bend the patch carefully and make sure you apply even force to keep your bends straight. This takes a bit of back and forth work to check each bend as you go.

7. With the bends completed, try a test fit. At this point the big whole in my tunnel was completely covered.

8. Sand, paint or coat the patch to match your floor. I Herculined my floors so I did the same to the patch and let it dry. Later on you will be removing a portion of your new patch for the shifters to come through the floor so you may want to wait to paint the patch until the end of this project.

Fabricating the Twin-Stick Shifters

1. The first thing to establish here is what transmission you are using and does it come with a mounting bracket for the 4x4 shifter. In my case Advanced Adapters provided this backing bracket with the NV3550 kit. All I needed to do was drill a 7/16 diameter hole in the center for the pivot point of my shifters. For you, you may want to fabricate a bracket of your own depending on your transmission. A simple solution is a flat metal bar with 3 holes drilled into it. [The correct length will vary depending on your application.] Your mounting bracket will require two outer holes to be drilled for mounting the shifter to the transmission and one hole drilled in the center to mount the pivot point for your shifters. With my setup I drilled a 7/16 hole into the center of the bracket supplied by Advanced Adapters. I then welded the 7/16 course thread 4 ¼ inch grade 5 bolt used for the pivot point. Later this 7/16 bolt was trimmed to the exact length required.

2. With my high quality napkin and tin foil I made 2 bendable templates for the upper rods of the shifter. I started by rolling the foil with the napkin in the center and then cutting the foil rods into two 12 inch length.

My goal here was to first shape the rear axle shifter then the front axle shifter. I wanted to have the end result to allow clearance for the two shifters to be able to move freely with out binding up when the shifter knobs were installed. Also I wanted them to be low enough to allow for full shifting of my NV3550 shifter in all gears and for clearance to my left knee to not hit at all. Last but not least the ending product had to be able to fit under my sheet metal patch for the floor. Easier said than done.

3. With the mounting bracket installed onto the transmission I next installed two 1 ½ inch long pieces of drilled metal rod onto the pivot bolt. The shifters and lower arms will later be welded to these with washers and a lock nut.

4. I designed the rear axle shifter to be in 2 wheel high when the shifter was in a low position on the floor with the shifter knobs both being at an equal height when in all positions. Forming the foil rod here took some practice, imagination for future clearance, and some trimming. At this step I marked on the inner tube with a Sharpie the position of the foil rod and drew two alignment lines from the foil rod to the tube.

5. I repeated this step for the front axle shifter. To make sure I was going to have the desired end result I had a flat piece of card board I used to cover the large tunnel hole to represent the sheet metal floor patch. I trimmed a small hole in the card board allowing for the foil rods to poke up through the floor.

I used a small amount of blue masking tape to hold the shifters in place at times while I shifted the foil rods through all positions.

6. To bend the metal rods I strongly recommend you cover the threaded end of the rod with a lot of making tape. Don’t screw up the threaded ends of the rods. Start from the top of the rod and make your way down. This helps to protect the threaded end from accidentally being crushed when using the long pipe/breaker bar to bend the rod.

7. Starting with the first bend, compare the foil rod to the metal rod marking on the metal rod a line where the first bend is to be done. Carefully place your metal rod in one side of your vice, the foil rod in the middle, and a small 1 inch piece of scrap metal rod on the left side in the vise. Line up the mark on the metal rod with the edge of your vice, place your long pipe/breaker bar over the metal rod and slowly bend.

This was tricky and very time consuming. You will do step 7 over and over before achieving the correct shape of your metal rods.

8. You may want to cut the non-threaded ends of the shifters to the correct length for your application. This will very depending on your body lift height. Try to contour the end of the rod with the grinder so it will fit over the pivot point metal tubes.

9. Tack the rods into place but do not weld them completely just incase you need to reposition them later.

10. With the rods tacked in place, remove the protective tape from the threads and mount your shifter knobs. Try moving them freely, imagining where you want the final location of 2 wheel high and 2 wheel low to end up.

11. At this point I found the metal tubes could be trimmed allowing the shifters to be installed closer together. I trimmed them just a little at a time, installed the 7/16 washers, and the lock nut loosely.

12. Cut two pieces of the 1 metal bar, a 3 inch, and a 4 inch piece. Cut out a shape with two long outer finger which fit over the metal tubes at the bottom of the pivot(See the parts photo). The rear axle arm will be somewhat shorter than the front axle arm. Grind out a slight angle on the inside of the bar between the fingers.

13. Drill a ¼ inch hole about ½ an inch away from the end of the two bars. Take some time to view the movement of the arms under the metal tubes. When I got the angles right here I tack welded them into place.

14. Cut two pieces of ½ inch wide card board strips. These will connect the bottom of your shifter arm to the transfer case rails. At this point the length will vary. The rear shifter connection bar was about 3 inches and the front shifter connecting bar was almost 5 inches long. Your exact length will vary. (The pair in the photo were too short, I made another set) Double check the movement with the card board connecting bars first. Next cut to length your metal bars and before you start to do any bending, drill 2 ¼ inch holes at the ends of each.

15. To bend the lower arms of the shifter I placed it in the vice and used a large adjustable crescent wrench to make my final adjustments. Keep the bends in the middle of the bars not at the ends. The ends will require flat surfaces for the connections at the clevis pins to move freely. Also some twist will be needed to make the connection rods move freely. Try assembling the shifter and moving it check to make sure it doesn’t bind up.

16. Cut the clevis pins to length and welded them into place on the lower arms of the shifter. At this point I did my final welding making it very solid.

17. Paint. I filed the metal tooth marks from my vise off, cleaned the metal with acetone, masked off the threaded ends and gave the shifters 2 coats of semi-gloss black paint. I also prepped and painted the sheet metal screws too.

18. Finally I installed the twin-stick shifters, trimmed the sheet metal floor patch, and installed the patch, and shifter boot. The trim ring did also need some adjusting to make it fit flat on the floor.

After all said and done I am very happy with my ending result. If anyone has questions please feel free to contact me.

Chris taipeichris13@yahoo.com