dirwin

New Member

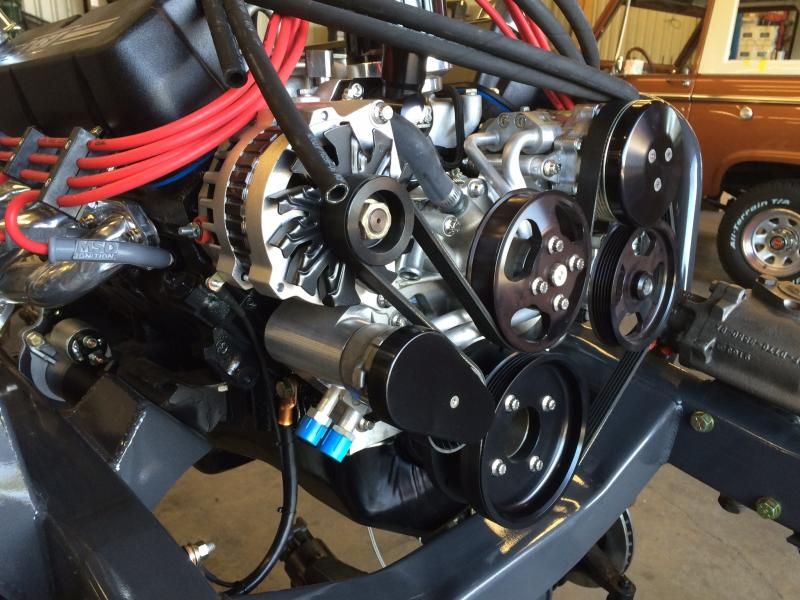

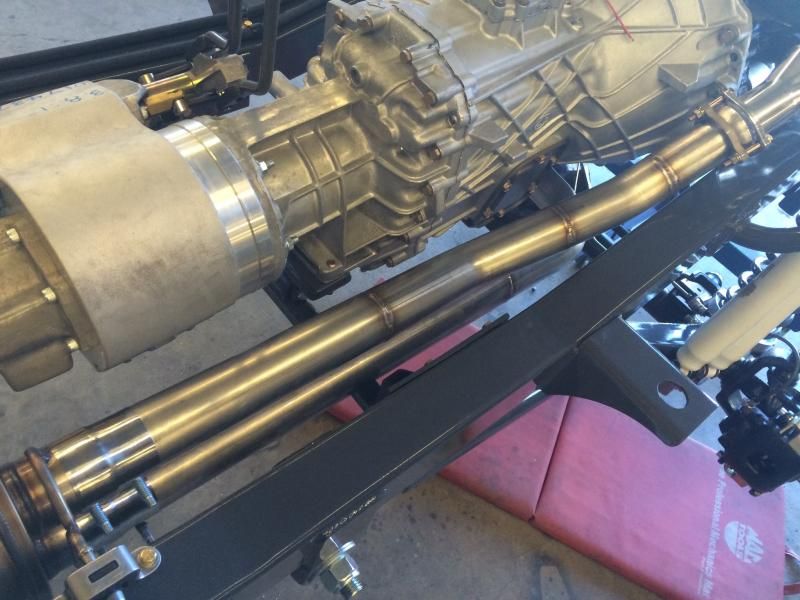

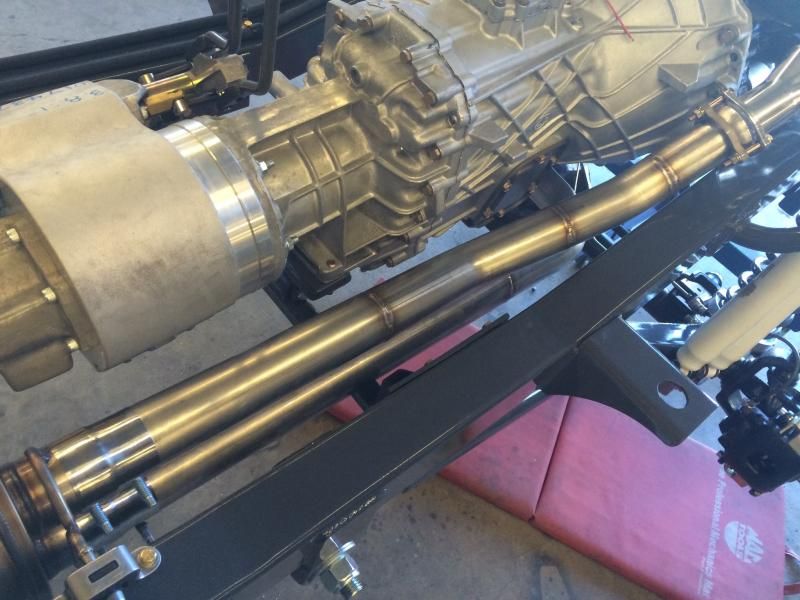

Just started getting going on the chassis of my 72. The frame was absolute crap so I went with a new JBG frame. With this one I decided to go with a 3.5" James Duff suspension, 2" body lift, 351/ZF/Atlas driveline and went with BC Bronco's headers.

I've not really cared for the pre-bent exhaust that's out there, it's good and functional and all, I just don't care for the plain look and heaven knows I love to over complicate stuff for myself. So I decided to teach myself how to tig weld stainless and do a 2.5" mandrel bent, weld up exhaust myself. I'm an absolute amateur with the tig but I did decide to do a merge pipe and exhaust on my Mustang prior to taking on the Bronco. I've got to give props to another website here though, Jody at www.weldingtipsandtricks.com is absolutely a fantastic resource, his videos that he post for free are a great tool.

So, I ordered a bunch of 2.5" 16 gauge 304 stainless bends, 15, 30, 90 and 180 degree bends, one 2 in, 2 out Magnaflow muffler with the internal crossover and a new bimetal blade for the bandsaw and away I went. My goal was a single muffler dual setup that brought 2 pipes out the passenger side. Here is the photo trail of the work. All I lack is one hanger on the rear pipe section that I should be able to do tonight after work.

One observation I will make, I am very impressed with Chuck's headers, of all the headers I've used so far with the Broncos, these are by far the best.

I've not really cared for the pre-bent exhaust that's out there, it's good and functional and all, I just don't care for the plain look and heaven knows I love to over complicate stuff for myself. So I decided to teach myself how to tig weld stainless and do a 2.5" mandrel bent, weld up exhaust myself. I'm an absolute amateur with the tig but I did decide to do a merge pipe and exhaust on my Mustang prior to taking on the Bronco. I've got to give props to another website here though, Jody at www.weldingtipsandtricks.com is absolutely a fantastic resource, his videos that he post for free are a great tool.

So, I ordered a bunch of 2.5" 16 gauge 304 stainless bends, 15, 30, 90 and 180 degree bends, one 2 in, 2 out Magnaflow muffler with the internal crossover and a new bimetal blade for the bandsaw and away I went. My goal was a single muffler dual setup that brought 2 pipes out the passenger side. Here is the photo trail of the work. All I lack is one hanger on the rear pipe section that I should be able to do tonight after work.

One observation I will make, I am very impressed with Chuck's headers, of all the headers I've used so far with the Broncos, these are by far the best.