Notice there is a "spout" with no tubes/hoses attached to it on the top-left side of the engine, is this supposed to be connected somewhere?

To the air cleaner housing.

It is your "fresh air return" for lack of a better term. It's the backside of your PCV (positive crankcase ventilation) system and is very important.

Every time you run the engine, outside air is being sucked into the engine through that fitting. So it needs to be connected to the clean air side of the air filter.

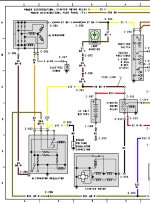

Notice in the driver's side valve cover (literally the opposite corner to the fitting you're asking about) there is your oil filler cap with the PCV valve sticking out the center.

The valve is connected directly to engine vacuum, usually at the base of the carburetor, and sucks dirty air from inside the crankcase, back into the intake where it's burned along with the new air/fuel mixture.

Because it's sucking out the bad, you need the other fitting to be sucking clean air back into the crankcase.

You have a rarity there, in that the carburetor still has the bowl vent for the charcoal canister, and the data tag under one of the top screws.

It's very possible that you have the original carburetor. If not, then at least someone went to the trouble of getting the correct replacement, and leaving the data tag on the new carb.

Either way, the point I'm eventually going to get 'round to, is to NEVER throw away the tag, or let it go with your old carburetor as a core for a new one.

In fact, even if you do get a new or rebuilt carburetor, don't get rid of the old one until you know for certain that the new one is the same thing.

Once it's been turned over as a core, your old one is virtually gone.

Speaking of the air cleaner and the charcoal canister (evaporative emissions system, or EVAP), that 3/4" diameter fiber-like hose sticking up behind the wheel house is from the charcoal canister mounted to the frame rail. There should be two of them.

One goes to the air cleaner, and one just stays there letting outside air into the canister.

The bowl vent with the hose on top of your carburetor should go down to the canister as well.

Paul