Crews-

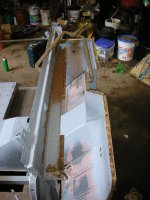

My advice would be to do your panel replacement before you media blast. If its pretty bad in some areas, you can pre-blast it with some "black beauty" or similar (not panels, but floors, cowl, rockers, kick panels...ie--places you will likely need to do repair. Spot blasting the problem areas allows you not to have to freak out about the rest of the body. Get those areas cleaned up, do the metal fixes/replacements, THEN take the finished product in for media blasting. That way you dont have a project that languishes around un-protected. As I did an area, I used cold-galvanizing compound or weld-thru primer....which was all later stripped in the media blasting stage, from there it went to primer.

So, the answer to the other half of your question is YES, do use a primer. Epoxy or a quality etching primer is what you want below your liner. Epoxy is probably the best, but you need to check with the Liner-product that you will be using to make sure if its compatible and to find out what the cure times in between need to be. I went with Line-X...underneath it we sprayed an etching primer. I wanted epoxy, but was assured that the etch-primer would provide excellent rust prevention and adhesion properties for the Line-X.

Another thing to consider...what "media" will you be using for your "blasting". SOme of my panels were done in soda, some with silica or alumina, some were a little coarser. All of my panels were metal conditioned afterward to ensure that any soda was quenched and removed prior to primer. Soda leaves a residue that gets into the pores. This is great for storage, b/c it acts as a rust inhibitor, but if not quenched and removed ( by dilute acid wash--usually phosphate --metal conditioner. Some use vinegar, but there are better products...thats what metal conditioners are for and they promote adhesion)..as I was saying...if not quenched and removed, the bicarbonate (soda) will react with the paint, affect adehesion and likely bubble and ruin the paint job.

Let us know what products you are using. You really should consult someone 'in the know' and not go by just internet gossip...not when it comes to paint. What may work for one guy and another guy may not work for you if you combine their two partial methods. Make sure that the plan and materials you plan to use will work well in conjunction with each other. Thats why there are "paint systems" and "product lines"...some of it is marketing, but alot of it comes down to science as well...so make sure you do your research and talk to some pros or experienced folk who can give you solid advice.

Good luck. ...while it was alot of work, some of the most fun and "best learning" I had during my project was doing the stripping, welding, fabrication and sheet metal repair. Try to think about upgrades or personalizations you want to do now and try to factor them in...access panels, sealing up unused holes, etc. It sucks to have to cut, weld or re-engineer something that you have already "finished". Installing upgrades and configuring the truck before and during tear-down, makes reassembly much faster. Keep in mind tolerances will become tighter once you have 1/16, 1/8 or 1/6" thick bedliner on everything.

Again...Good luck!

John