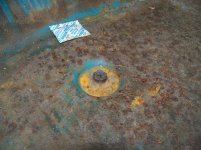

Anyone got any ideas how to take care of gettin' these jokers out? PO must have put something around the bolt to lock er' down tight as a drum to the body. My one inch body lift is on hold till I figure a way to get these damn things out.

Help-- give some ideas,,,,

Help-- give some ideas,,,,