As always, thanks...

Where exactly is the vacuum modulator?

Oh, and fluid level is over full...

C4 Modulator location:

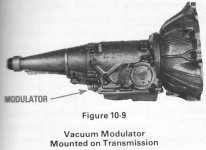

The Vaccuum modulator is located at the rear of the transmission on the right side, just above the pan and the canister that houses the diaphram points towards the rear of the vehicle.

No 3rd gear shift

A number of things can cause a no 3rd shift condition. The most common seem to be usually a malfunction in the vacuum modulator system. The following are a list of preliminary things to check on your vacuum modulator circuit.

1) Make sure there is a good intake manifold vacuum signal reaching the vacuum modulator. Trace the vacuum line from the back of the intake manifold down the bell housing toward the back of the trans. Make sure the line and hoses are in good shape and capable of delivering a good vacuum signal to the modulator located just above the pan on the right rear side of the trans. Sometimes a simple replacement of a vacuum hose will cure the problem. A good vacuum signal will be 14-18 in.Hg on your vacuum gauge at the modulator @ idle. Not every C-4 can be expected to perform well if these vacuum readings are not met. A worn engine, and or poorly tuned carburetor, or ignition can cause a poor or inadequate vacuum signal.

2) Make sure the vacuum modulator itself is not bad or broken. If you remove the hose from the vacuum modulator and transmission fluid comes out of the hose connection, this is an indication that the vacuum modulator diaphragm has a hole in it and is considered bad or broken and in need of replacement. I usually check them with a hand held vacuum pump, and a postal scale. If you are in doubt or don’t have the proper tools to check the operation, replace the modulator. Sometimes these checks can indicate a good modulator and the vacuum modulator tested can still be bad. When in doubt, replace it with a good OEM brand like Century Brass, Scovill, or Rostra Controls.

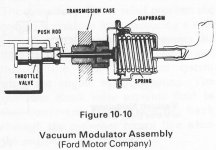

3) Be certain the vacuum modulator valve inside the transmission case moves back an fourth freely and is installed properly. The shaft at one end of the spool valve will be pointed toward the rear of the car when installed properly.

4) The modulator pin needs to be in place. This is a steel pin that is about 3/32” in diameter and about 1 ½” long. This pin is the link that goes between the vacuum modulator diaphragm and the spool valve, and is absolutely needed for proper function of the modulator circuit.

Modulator Pressure;

The pressure is increased by a drop in the intake manifold vacuum signal coming from the engine. This signal actually increases or decreases the spring tension on the modulator valve and by doing this boosts a certain circuit of hydraulic pressure inside the transmission. If your engine is running good and well tuned, it may be delivering too strong of a vacuum signal to make the transmission behave satisfactorily. One of the ways you can compensate for this surplus of good vacuum is to either change the modulator to a different one or re-calibrate the existing one. The latter is only for fine tuning and should not be used for severe changes.

Adjusting the Screw;

To increase modulator pressure, you turn the screw in as if you were tightening the screw. To decrease modulator pressure, you turn the screw out as if you were loosening the screw. Increasing modulator pressure will cause the shift points to be later and firmer. Decreasing modulator pressure will cause the shift points to be sooner and softer. Turn the screw 1-2 full turns at a time then test drive the vehicle. Repeat the procedure, if necessary until desired results are reached. !Do NOT turn the screw more than 4 FULL TURNS in either direction from the factory preset or damage to the modulator could occur! The modulators come pre-set from the factory with a neutral adjustment, which is approximately 1 to 3 turn in from flush with the end of the mod. from this point, backing out the screw will do probably nothing. To increase modulator pressure you tighten the screw. Do not exceed 4 turns.

Adjustment screw location:

All 6 versions may or may not have an adjustment screw, which is usually located inside the vacuum hose connection with the exception of the red-stripe modulator. You will find the adjustment screw by unplugging the hose connection to the modulator at the trans. The red stripe dual input version, the screw is not located inside the hose connection but in the center rear of the diaphragm housing. The adjustment screw on the red-stripe dual modulator is found at the rear and not inside the hose connection. It cannot usually be adjusted unless the retainer is removed.

Types of vacuum modulators available for the C-4 and C-5:

Push-In or Bracket Mounted Modulators:

1) Red-stripe with two vacuum inputs. (large & small) Usually found on earlier (73-74) vehicles where EGR Devices were first introduced. This can in most cases be replaced with the green stripe version and get better results for the shift characteristics. The red-stripe dual diaphragm equipped C-4s use a different modulator retaining clip. This retaining clip is held in place by an extension housing bolt that is located just above the modulator. When changing the modulator to a single diaphragm type, you need to get the correct retainer from the dealer or the boneyard. C-5s also use the same C-4 retainer made for the single diaphragm modulator. The dual diaphragm retainer will cover access to the hose connection on the single diaphragm modulator. The retainers are made of spring steel.

2) Yellow stripe, with one single hose connection for High Vac lower altitude driving. Usually found on larger engines with strong vacuum signals, and trucks with earlier governor shift point calibration. Usually found on 72-81