- Joined

- Oct 25, 2016

- Messages

- 941

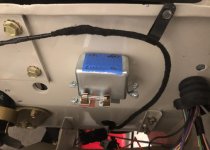

OD Relay

After a lot of fruitless searches for the “ correct” placement of some of the components, I’ve made some decisions. By correct, I mean where the techs at Ken Roggy Ford would have installed them back in 1968. For the OD Relay, I have installed it on the outer firewall on the drivers side. The OD cable release handle will be situated to the right of the emergency brake handle. I found a nice 1968 Mustang air vent cable bracket to secure it.

I am providing a pic of the relay with the notes on which terminal leads where. If I’ve made any mistakes, I will correct it as I proceed. Also, a pic of the underside view of the kick down switch as it is installed in the floorboard under the gas pedal. I’m currently underway with building my wiring harness which will connect the relay, OD solenoid, kick down switch, and governor.

After a lot of fruitless searches for the “ correct” placement of some of the components, I’ve made some decisions. By correct, I mean where the techs at Ken Roggy Ford would have installed them back in 1968. For the OD Relay, I have installed it on the outer firewall on the drivers side. The OD cable release handle will be situated to the right of the emergency brake handle. I found a nice 1968 Mustang air vent cable bracket to secure it.

I am providing a pic of the relay with the notes on which terminal leads where. If I’ve made any mistakes, I will correct it as I proceed. Also, a pic of the underside view of the kick down switch as it is installed in the floorboard under the gas pedal. I’m currently underway with building my wiring harness which will connect the relay, OD solenoid, kick down switch, and governor.