It also depends upon the machine you have. I have an older basic machine (chinese) that I've upgraded with bead rams, bead puller, and center post adapter kit.

But the rams especially, are on large arms that have some play. Occasionally, they move around and could cause some rim damage. Also, the main head is metal and

requires plastic inserts (they do make non metal heads, but mine has the integral bead puller). If the plastic inserts are worn, again, possible damage on outer edge of rim.

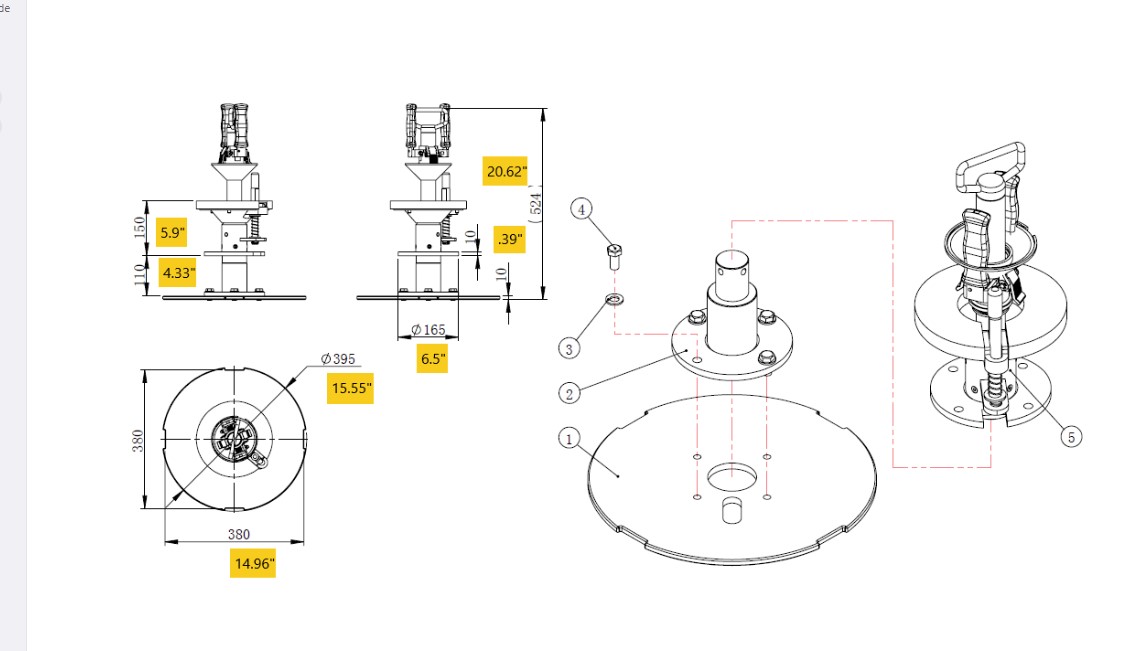

The new high end machines have some of these the items on ACME threaded rods, that are solidly mounted, so no flex. They don't use a traditional head, they use a

non-metal disk that can break down bead and/or push down bead for de-mount. Like this

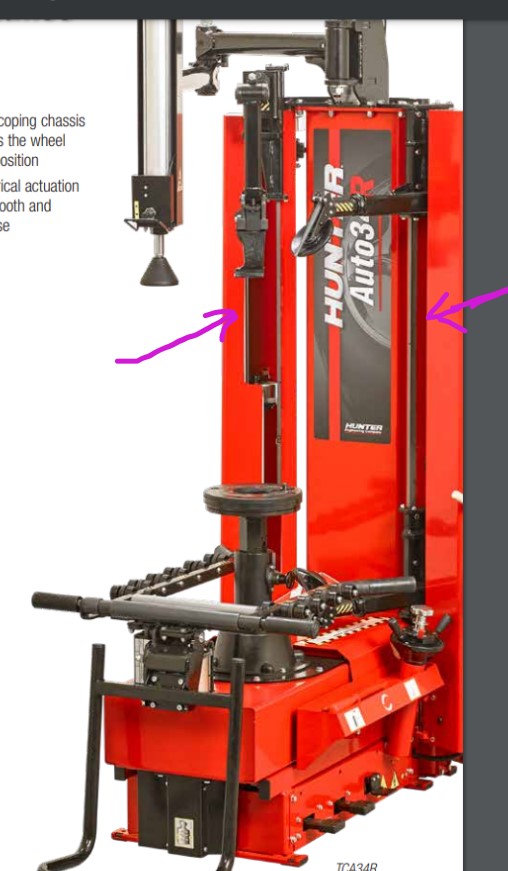

So yes, you need a good tech who gives a crap about their work, but the newer equipment (if you know how to use it), can greatly reduce rim damage also.

Can ask the place exactly what machine they have, go look it up and see if it appears to be more like this new hunter, than an older POS like mine.