murdador

Mr. Member

- Joined

- Aug 6, 2017

- Messages

- 160

Hey Guys,

I have a '69 that has a dana 44 installed from the previous owner. I managed to get my hands on 78-79 knuckles and related brake hardware. Everything has come together fairly easy, except the locking hubs. I bought new '79 wheel hubs but I'm trying to use the old locking hubs. They fit but it super tight and do not slide easy at all even with enough grease to swim in.

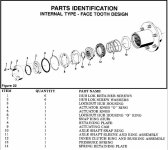

What am I missing? Are the locking hubs specific to the drum wheel hubs because they fit and function perfectly in them. Do I need to bite the bullet and get new locking hubs? Attached is a diagram of what my locking hubs look like.

Any advice would be greatly appreciated.

Thanks,

Pedro

I have a '69 that has a dana 44 installed from the previous owner. I managed to get my hands on 78-79 knuckles and related brake hardware. Everything has come together fairly easy, except the locking hubs. I bought new '79 wheel hubs but I'm trying to use the old locking hubs. They fit but it super tight and do not slide easy at all even with enough grease to swim in.

What am I missing? Are the locking hubs specific to the drum wheel hubs because they fit and function perfectly in them. Do I need to bite the bullet and get new locking hubs? Attached is a diagram of what my locking hubs look like.

Any advice would be greatly appreciated.

Thanks,

Pedro