houseofdiesel

Jr. Member

- Joined

- Dec 26, 2008

- Messages

- 253

Update 9/23/11

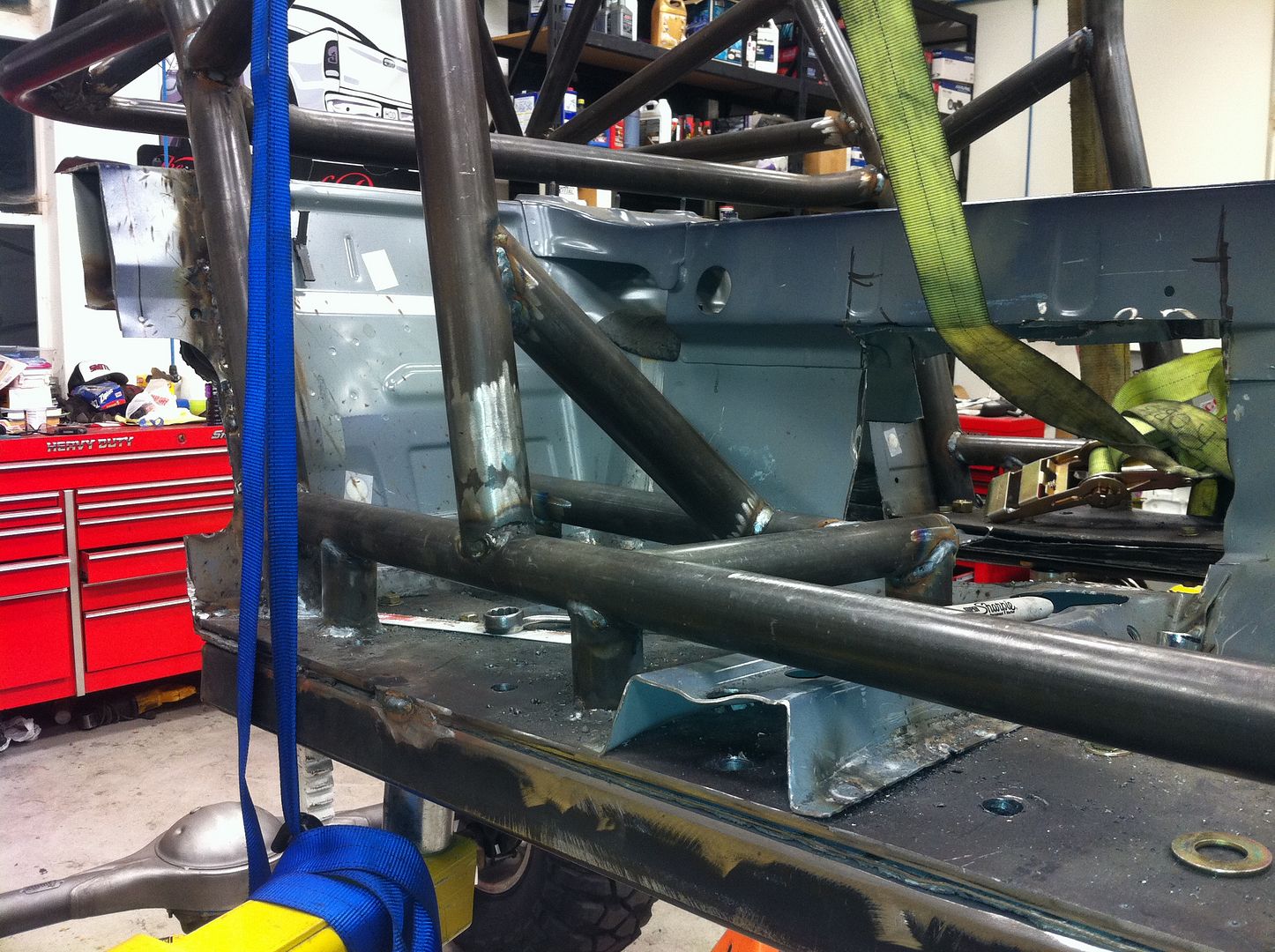

So got the front motor mount ears braced up, and the rear one link main bracing cut and in. Coming together nice. Let the wife throw down some welds on the inside of the skid and cut the bracing. She did pretty good for her first day. I even laid down my first ever TIG welds. Only did a couple open spots where I could get set up at good easy angles. Inside corners, weren't going very smooth once things started to get boxed in, so I'll just need to practice a bit more before I feel comfortable TIGing full time. I love it though and can't wait to get the hang of it, and figure out all the tips and tricks to tough spots. So plan is once I finish all the bracing, I'll drop the motor to finish welding all the tight spots, box in the front and rear one / uni link brackets, and paint things up. Ordered axle bracket, and trac bar hiems tonight, so progress should stay pretty steady. It'll take a little bit extra time to make sure all the links are bent perfectly to 90 to the axles, so that if I ever need to adjust the pitch of the axles or tweak the distance of the axles further out I can. It won't have more than a 1"-1.5" of adjustment but it's nice to at least be able to adjust the pitch of the axle, instead of the tubes being welded directly to the axles and never being able to adjust anything. If you are questioning the design, don't worry you'll see it very soon, 2-3 weeks max.

So got the front motor mount ears braced up, and the rear one link main bracing cut and in. Coming together nice. Let the wife throw down some welds on the inside of the skid and cut the bracing. She did pretty good for her first day. I even laid down my first ever TIG welds. Only did a couple open spots where I could get set up at good easy angles. Inside corners, weren't going very smooth once things started to get boxed in, so I'll just need to practice a bit more before I feel comfortable TIGing full time. I love it though and can't wait to get the hang of it, and figure out all the tips and tricks to tough spots. So plan is once I finish all the bracing, I'll drop the motor to finish welding all the tight spots, box in the front and rear one / uni link brackets, and paint things up. Ordered axle bracket, and trac bar hiems tonight, so progress should stay pretty steady. It'll take a little bit extra time to make sure all the links are bent perfectly to 90 to the axles, so that if I ever need to adjust the pitch of the axles or tweak the distance of the axles further out I can. It won't have more than a 1"-1.5" of adjustment but it's nice to at least be able to adjust the pitch of the axle, instead of the tubes being welded directly to the axles and never being able to adjust anything. If you are questioning the design, don't worry you'll see it very soon, 2-3 weeks max.