LSharpNM

Full Member

- Joined

- Mar 9, 2020

- Messages

- 164

Sorry Nvrstuk - didn't mean to hijack your thread. LsharpNM - do you have a preferred / recommended location to drill and tap in the servo unit to maximize flow? Trying to maximize likelihood of having quick enough responsive steering on road.

I can't tell you exactly where on a 4x4x2 box would be ideal since I don't have personal experience with them, but look where all the steering companies tap their boxes for an idea of the area I am talking about.

Here's an example:

Here's a thread on different boxes: https://www.pirate4x4.com/threads/where-to-tap-a-saginaw-power-steering-box-for-hydro-assist.2702761/#post-44988344

You might have to pull your servo apart to figure out the best spots.

Here's a thread of someone doing that on a Delphi box: https://irate4x4.com/general-4x4/276993-delphi-600-steering-box-tech-jeep-wj

I am porting directly in the large cavity (top of the cap) with the sector shaft and at the end of the piston (valve) at that farthest end of the box. For clarification, are you saying that these 2 spots don't have enough fluid volume?

I can see where porting a small return inner passage spot inside the box where fluid is channeled might not have the flow but could you explain why the 2 spots I mentioned wouldn't have enough volume?

Just don't want to have issues-thx

Not so much "volume" as flow rate being the issue. You are trying to move a larger volume of fluid in the same amount of time through the small passageways that power the piston in the steering gear. These passage ways are restrictive and slow down the flow of fluid which means you can turn the steering wheel faster than the hydraulics can keep up. When trying to steer quickly (think emergency maneuvers/counter-steering) it can feel like you don't have power steering at all and make it difficult to impossible to steer as quickly as you need to.

You can always just do it like you planned and see how it comes out, I don't have personal experience with the 4x4x2, so I can't say how restrictive the passageways are relative to other boxes, but regardless, going straight from the servo is always ideal.

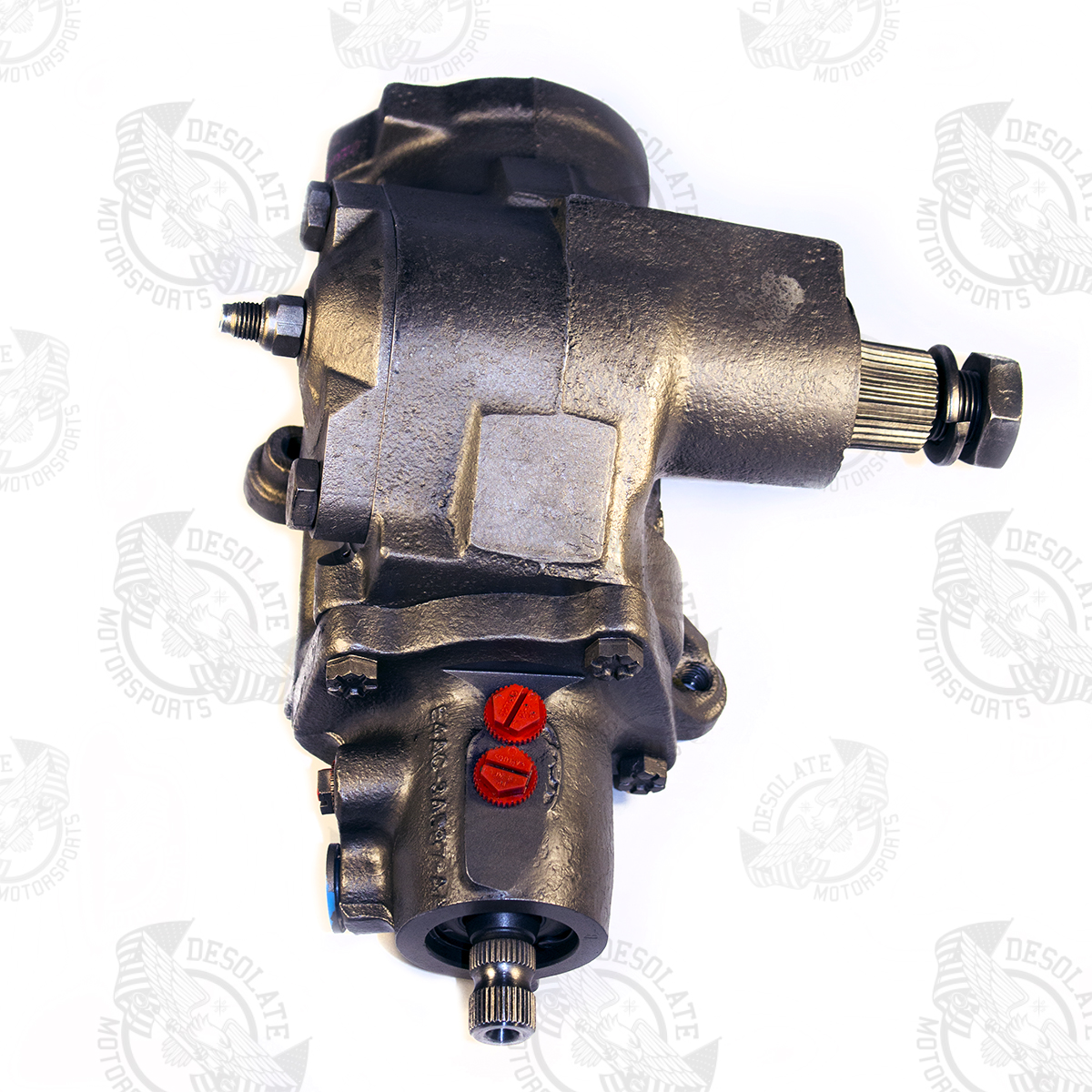

Y'all see a problem with porting at these locations (photos stolen from pirate4x4)?

These locations are basically the same thing as the locations nvrstuk is proposing from a flow perspective.