Brent13

Sr. Member

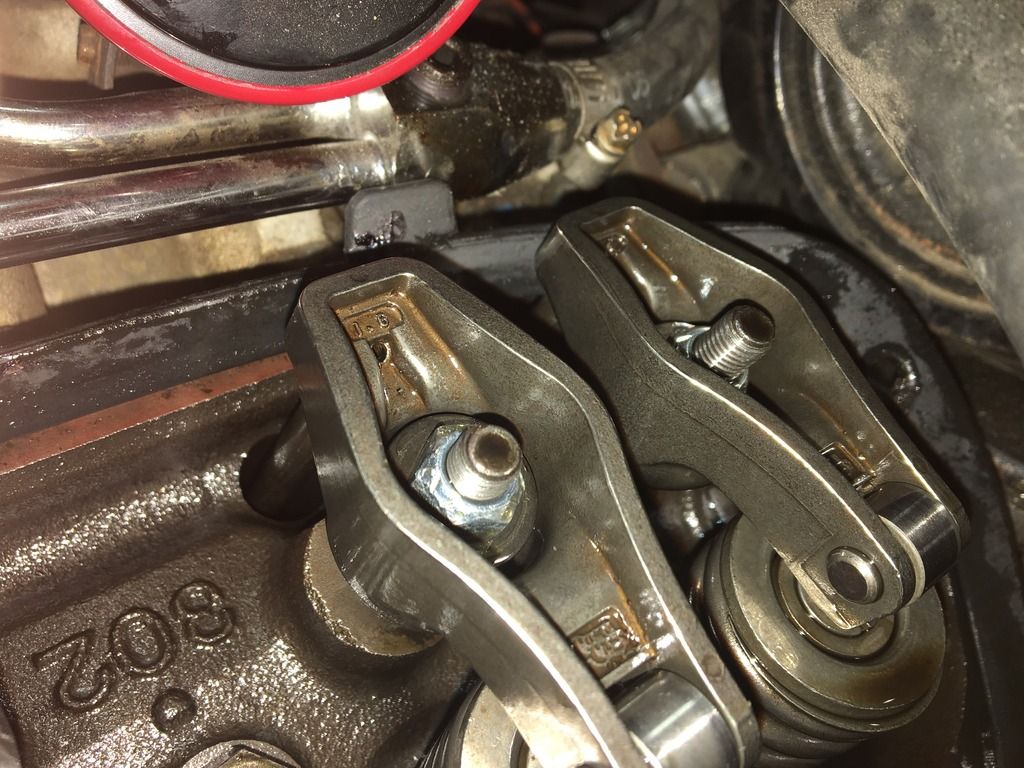

Can someone post a link, or explain the proper method of adjusting rockers/valves on a 1974 302? I have watched 20 YouTube videos, and they all seem different. I have had a rocker loosen up, #1 exhaust. Need to figure out why, and then will need a adjust properly. My rockers are roller tipped if that makes a difference. Last time I adjusted these rockers, I brought the cylinder to TDC, and adjust the intake and exhaust rockers by tightening down the nut while rotating the push rod. When the push rod stopped rotating, I went a full turn further on the nut. Is this proper procedure?

Thank you

Thank you