John Griswold

Jr. Member

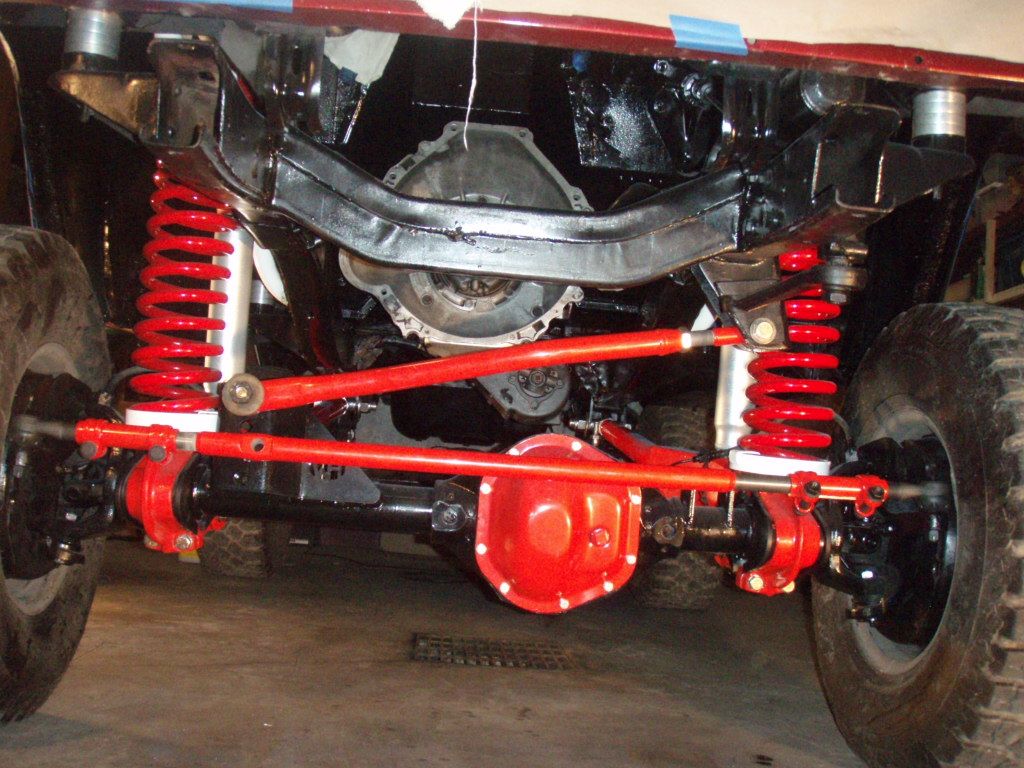

I'm looking to flip my tie rod over to the top to help with drag link angle. I've ordered the sleeves and reamer from BC Broncos to redrilll the holes from the top. First I was wondering if the holes can be reamed with a 1/2" hand drill with the knuckles still on the rear. Second, can it work with just trimming the lower track bar bolt where apparently there is a clearance issue when going tie rod over or has anyone used the Duff bracket that raises the lower track bar location? Raising the lower location would probably be beneficial in getting the track bar and drag link parallel. Anyone have any input on Duff' s bracket?

Thanks, John

Thanks, John