- Joined

- Mar 2, 2013

- Messages

- 2,672

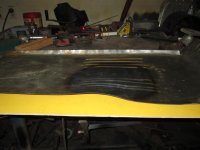

I was making a floor pan for the passenger side front floor today. I got it fitted and then rolled the beads , after I rolled the ones in the middle the pan warped up pretty bad. Is there any way to take out the warp or just scrap it and start over? Thanks in advance.