- Joined

- Jul 5, 2009

- Messages

- 1,664

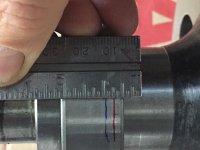

I'm installing a Zip Locker in my 9" that I am also upgrading from a 28 spline to 31 spline axle. The carrier bearings are the 2.89" versus a more standard 3.06" I'm guessing and the side adjuster nuts have a center hole that is smaller than the snout on the locker carrier.

Can I just open up the center hole on the adjuster nut to clear the carrier, or will that lead to another issue further into the install?

Can I just open up the center hole on the adjuster nut to clear the carrier, or will that lead to another issue further into the install?

Last edited: